Process for improving structure performance of wind power steel Q355

A technology of microstructure and performance, Q355NE, applied in the direction of temperature control, rolling force/roll gap control, etc., can solve the problems of wind power tower collapse, unqualified, performance difference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A process for improving the microstructure and performance of wind power steel Q355,

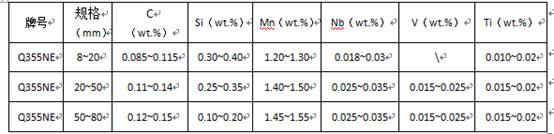

[0015] 1), Q355NE chemical composition (wt.%)

[0016]

[0017] 2) Optimal design of wind power steel rolling process parameters: After the composition design of wind power steel is determined, the rolling process adopts CR+ACC: controlled rolling and controlled cooling process mode for production, and the main path of wind power steel production process is that the slab passes through the heating furnace Heating, billet rolling by the rough rolling mill, and rolling into finished products by the finishing mill;

[0018] a. Optimal design of heating temperature: Under the premise of ensuring a certain composition structure, the heating temperature of the soaking section in the heating furnace area is optimized and adjusted to 1130~1180°C. Compared with the conventional temperature process, the grain size is increased by 0.5 grades, and the grains are more refined. Uniform;

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com