A kind of cobalt-based amorphous alloy thin strip and its preparation method and use

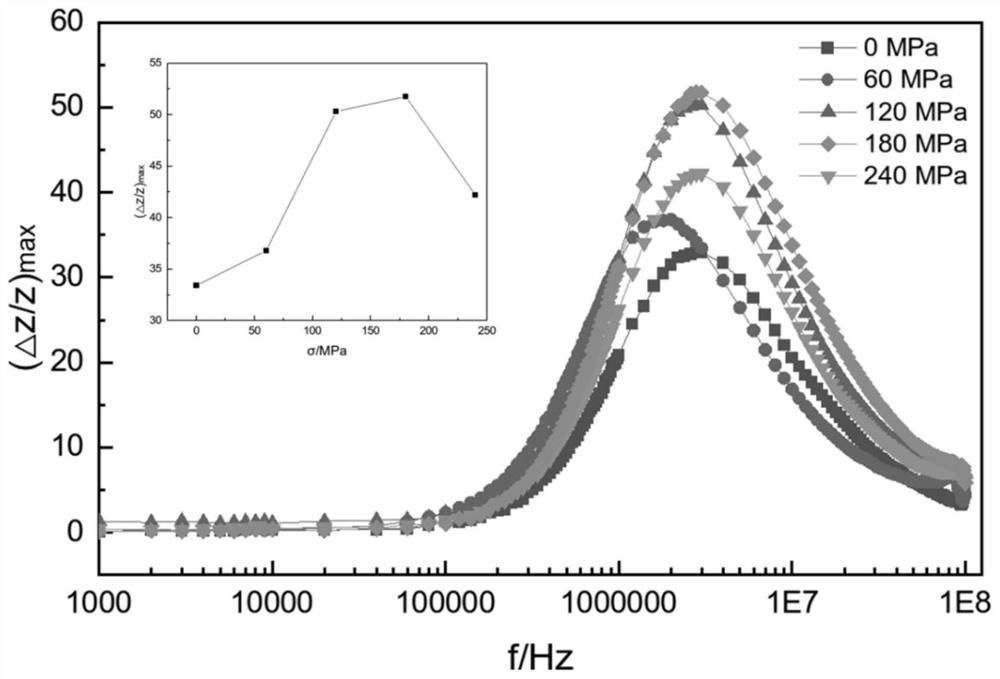

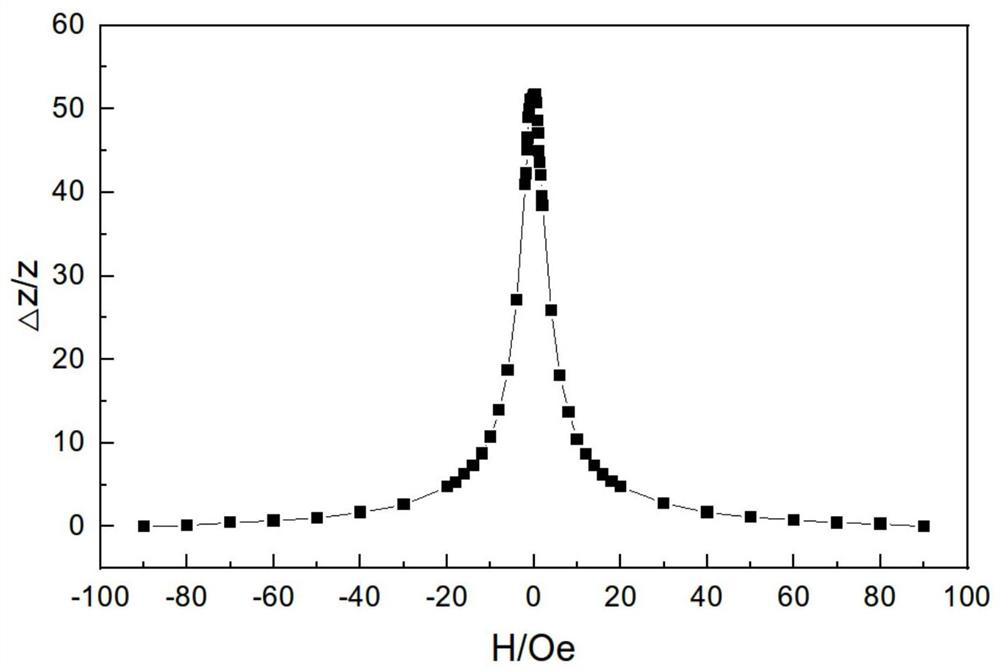

A technology of amorphous alloy and thin strip, which is applied in the field of cobalt-based amorphous alloy thin strip and its preparation, can solve the problems of poor soft magnetic properties, achieve high magnetic flux density, significant GMI effect, and difficult crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] In this embodiment, the preparation chemical formula is Co 68 Fe 6.5 Si 12.5 B 10 Nb 2 Ni 1 The cobalt-based amorphous alloy thin strip includes the following steps:

[0053] 1) Co, B, Ni, FeB, FeSi, FeNb with a purity of not less than 99.99% are converted into Co according to the chemical formula 68 Fe 6.5 Si 12.5 B 10 Nb 2 Ni 1 For ingredients, a total of 50g.

[0054] 2) The obtained ingredients were mixed and put into a crucible of a vacuum induction melting furnace, and in an argon atmosphere, smelted at 1500° C. for 20 minutes, smelted 3 times, and then cast into an alloy ingot.

[0055] 3) The obtained alloy ingot is broken, and the broken alloy ingot is then put into absolute ethanol for ultrasonic cleaning 5min and taken out to dry; the dry bulk alloy ingot is put into a high-vacuum single-roller spin-quenching belt In the machine, the molten alloy ingot was sprayed onto a copper roll with a rotating linear speed of 30 m / s for cooling to obtain an a...

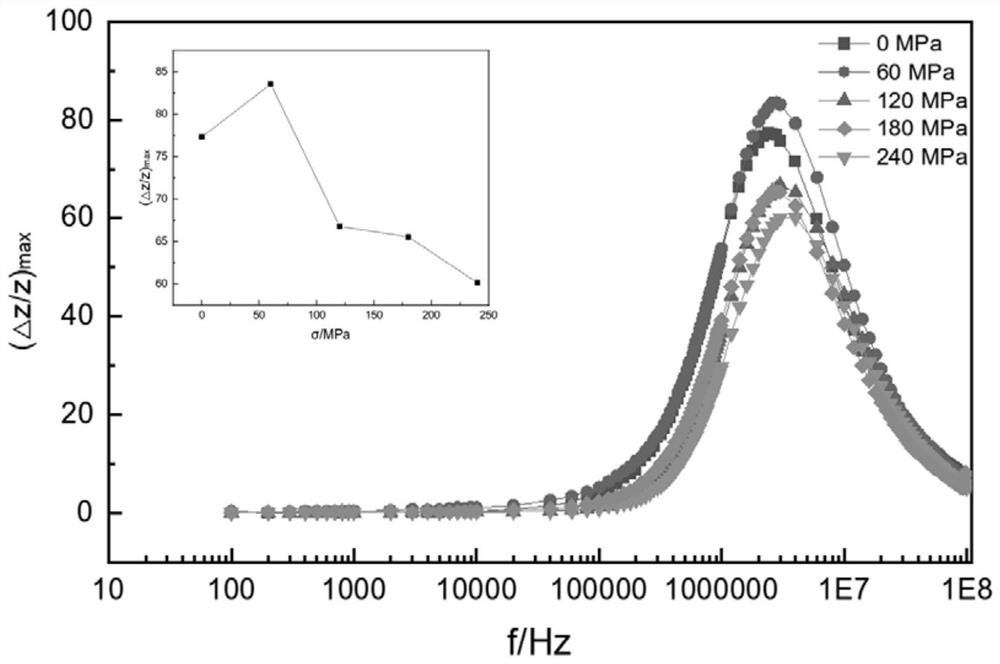

Embodiment 2

[0061] In this embodiment, the preparation chemical formula is Co 68 Fe 6.5 Si 12.5 B 10 Nb 1 Ni 2 The cobalt-based amorphous alloy thin strip includes the following steps:

[0062] 1) Co, B, Ni, FeB, FeSi, FeNb with a purity of not less than 99.99% are converted into Co according to the chemical formula 68 Fe 6.5 Si 12.5 B 10 Nb 1 Ni 2 For ingredients, a total of 50g.

[0063] 2) The obtained ingredients were mixed and put into a crucible of a vacuum induction melting furnace, and in an argon atmosphere, smelted at 1500° C. for 20 minutes, smelted 3 times, and then cast into an alloy ingot.

[0064] 3) The obtained alloy ingot is broken, and the broken alloy ingot is then put into absolute ethanol for ultrasonic cleaning 5min and taken out to dry; the dry bulk alloy ingot is put into a high-vacuum single-roller spin-quenching belt In the machine, the molten alloy ingot was sprayed onto a copper roll with a rotating linear speed of 20 m / s for cooling to obtain an a...

Embodiment 3

[0069] In this embodiment, the preparation chemical formula is Co 68 Fe 6.5 Si 12.5 B 10 Nb 0.5 Ni 2.5 The cobalt-based amorphous alloy thin strip includes the following steps:

[0070] 1) Co, B, Ni, FeB, FeSi, FeNb with a purity of not less than 99.99% are converted into Co according to the chemical formula 68 Fe 6.5 Si 12.5 B 10 Nb 0.5 Ni 2.5 For ingredients, a total of 50g.

[0071] 2) The obtained ingredients were mixed and put into a crucible of a vacuum induction melting furnace, and in an argon atmosphere, smelted at 1500° C. for 20 min, smelted 3 times, and then cast into an alloy ingot.

[0072] 3) The obtained alloy ingot is broken, and the broken alloy ingot is then put into absolute ethanol for ultrasonic cleaning 5min and taken out to dry; the dry bulk alloy ingot is put into a high-vacuum single-roller spin-quenching belt In the machine, the molten alloy ingot was sprayed onto a copper roll with a rotating linear speed of 30 m / s for cooling to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com