A wax spray method for reducing the corrosion dispersion of quartz wafer sheets

A chip corrosion and quartz technology, applied in the field of frequency components, can solve the problems of large corrosion dispersion of quartz wafers, etc., to achieve the effects of reducing dispersion, good versatility, and improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

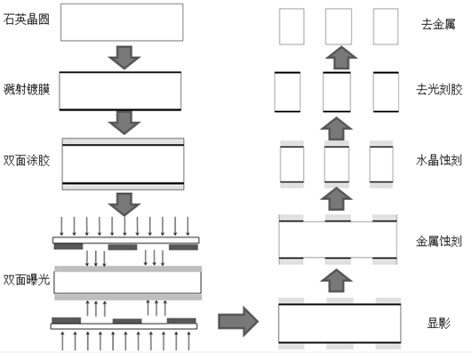

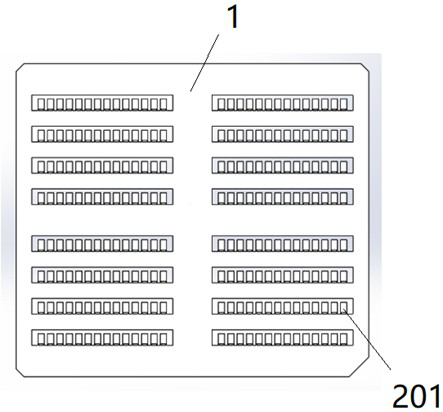

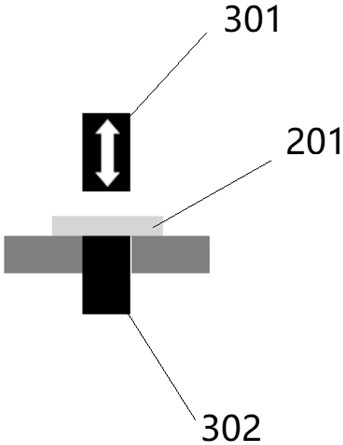

[0030] see Figure 1 to Figure 6 , a wax spray method for reducing the corrosion dispersion of quartz WAFER sheets, comprising the following steps:

[0031] 1) Process the incoming WAFER sheet of the quartz wafer, and sequentially perform double-sided sputtering coating, gluing, exposure, development, metal etching, crystal etching, degumming, and demetallization to obtain a corroded hollow quartz wafer 1;

[0032] The double-sided sputtering coating is to coat metal Cr and Au on both sides of the WAFER sheet;

[0033] The double-sided gluing is to apply photoresist on both sides of the metal surface of the quartz wafer 1;

[0034] The double-sided exposure is to expose the quartz wafer 1 coated with the photoresist with an exposure machine, and the light and the photoresist will react to change the properties of the photoresist;

[0035] The developing is to remove the reacted photoresist with a developing solution;

[0036] The metal etching is to remove metal Cr and Au w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com