Assembly type hoisting method and hoisting rod structure applied to exhaust fan supporting

A hoisting method and exhaust fan technology, which is applied in the direction of pipe supports, connecting components, mechanical equipment, etc., can solve the problems that the noise of the exhaust fan cannot be reduced, the structure of the exhaust support frame is complicated, and the construction period of hoisting is shortened, so as to achieve rapid and rapid improvement. Convenience, convenient and quick installation, shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

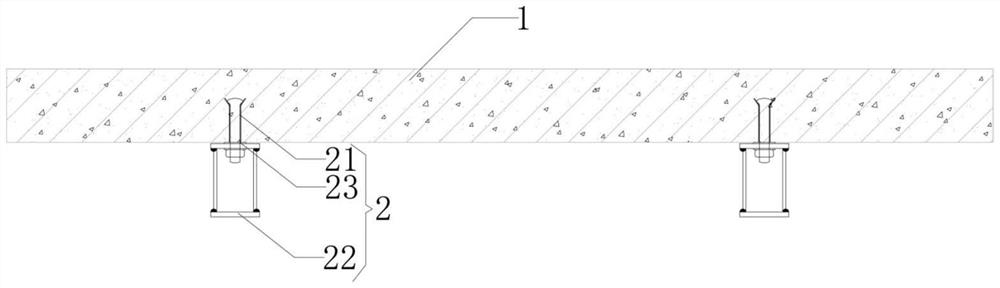

[0071] Such as Figure 11 As shown, another structural diagram of the structural adapter 22 of the present invention, the structural adapter 22 includes an upper flange 221, a lower flange 222, and a web 223, wherein two webs 223 are arranged on the upper Between the flange 221 and the lower flange 222, the two webs 223 are obliquely welded between the upper flange 221 and the lower flange 222, and the angle formed by the inclination of the web 223 and the lower flange 222 is 45-60 Between the upper flange 221 and the lower flange 222, the installation of the structural adapter 22 can be completed by welding the web 223 in the middle of the upper flange 221 and the lower flange 222. A structural connection hole 224 is punched on the lower flange 222, Two structural connection holes 224 are drilled, and the purpose of drilling two structural connection holes 224 is to install two expansion bolts, thereby enhancing the bearing capacity of the structural adapter 22 for hoisting, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com