Control system for zero-carbon flexible efficient cold source system

A zero-carbon flexible and control system technology, applied in control input related to air characteristics, air conditioning system, space heating and ventilation control input, etc., can solve the problems of large-scale curtailment, high energy consumption, and low energy efficiency, and achieve Improve work efficiency, save operating costs, and achieve the effect of carbon emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

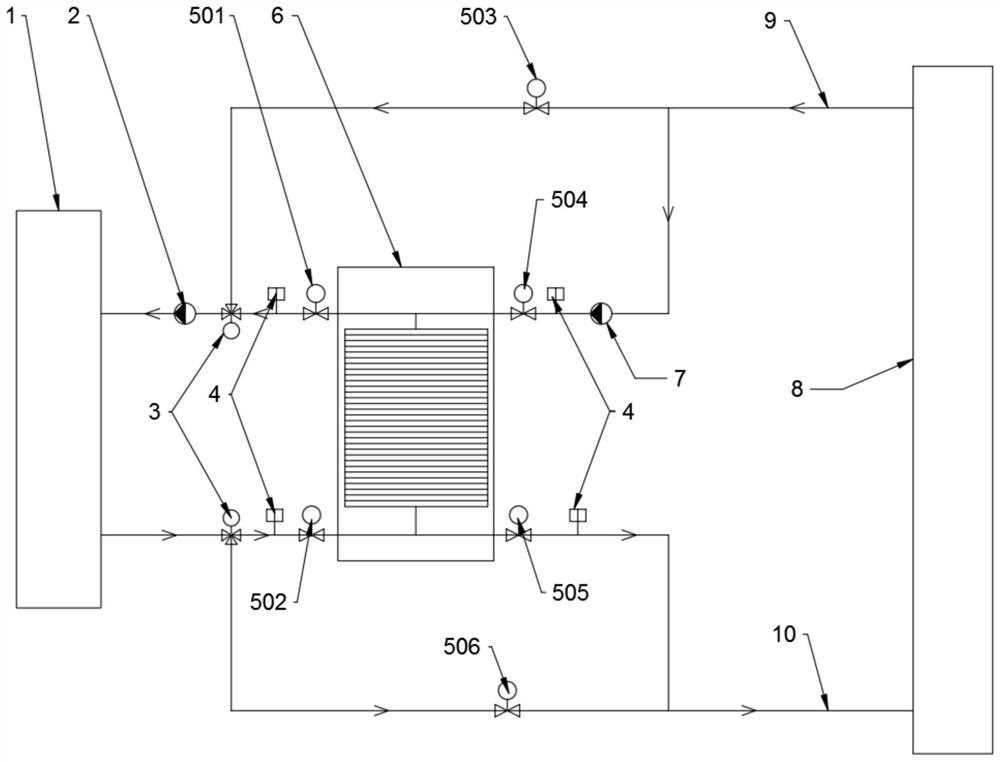

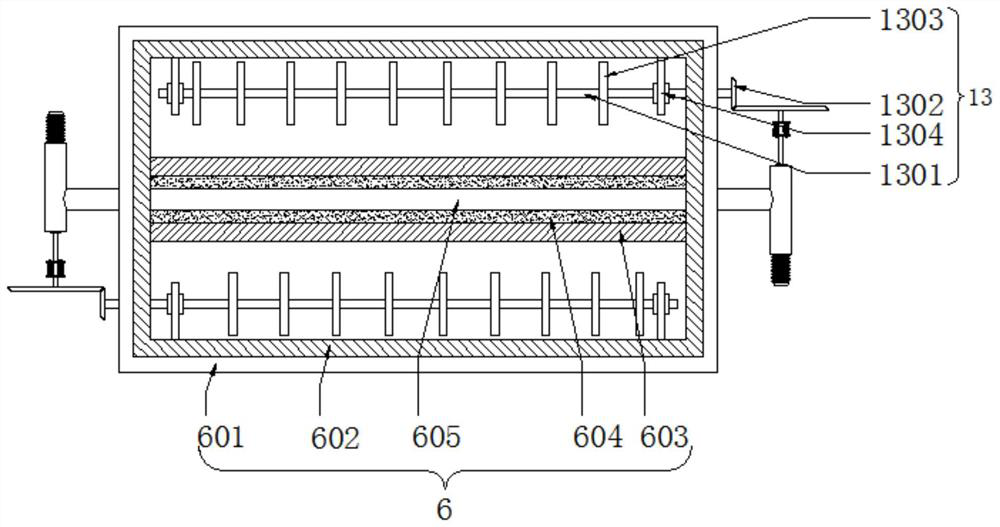

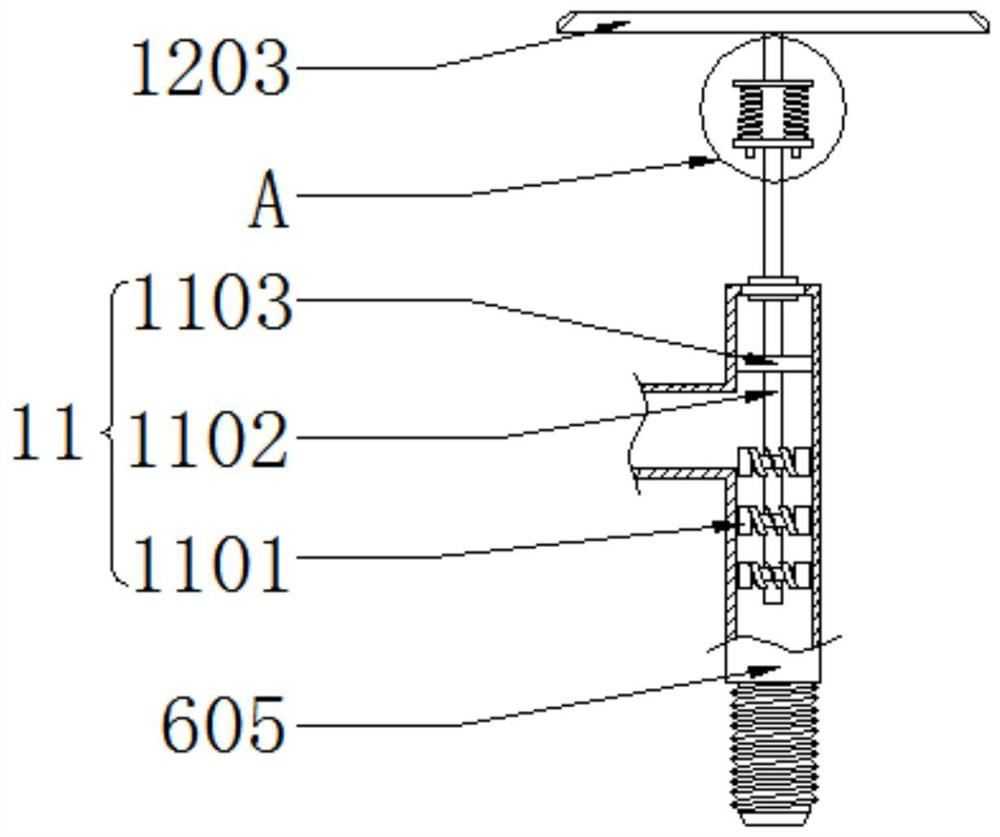

[0033] like Figure 1 to Figure 6 As shown, the present invention provides a technical solution: a zero-carbon flexible high-efficiency cold source system control system, including a magnetic levitation evaporative cooling integrated unit 1, a phase change cold storage tank 6 and a user side 8, the return water pipeline 9 of the user side 8 and The magnetic levitation evaporative cooling integrated unit 1 is connected through the electric valve three 503, the water supply pipeline 10 on the user side 8 is connected to the magnetic levitation evaporative cooling integrated unit 1 through the electric valve six 506, and the phase change cold storage tank 6 and the return water pipeline 9 on the user side 8 pass through The electric valve 4 is connected with 504, the water supply pipeline 10 of the user side 8 is connected with the electric valve 5 505, and the phase change cold storage tank 6 is connected with the magnetic levitation evaporative cooling integrated unit 1 water in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com