Speed reducer rigidity detection device

A technology for detection devices and reducers, which can be used in measuring devices, testing of machines/structural components, instruments, etc., can solve the problems of reducer spindle offset, affecting detection accuracy, and the clamping and fixing effect of reducer spindles in general, etc., to achieve Effect of reduced offset, precise stiffness data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention;

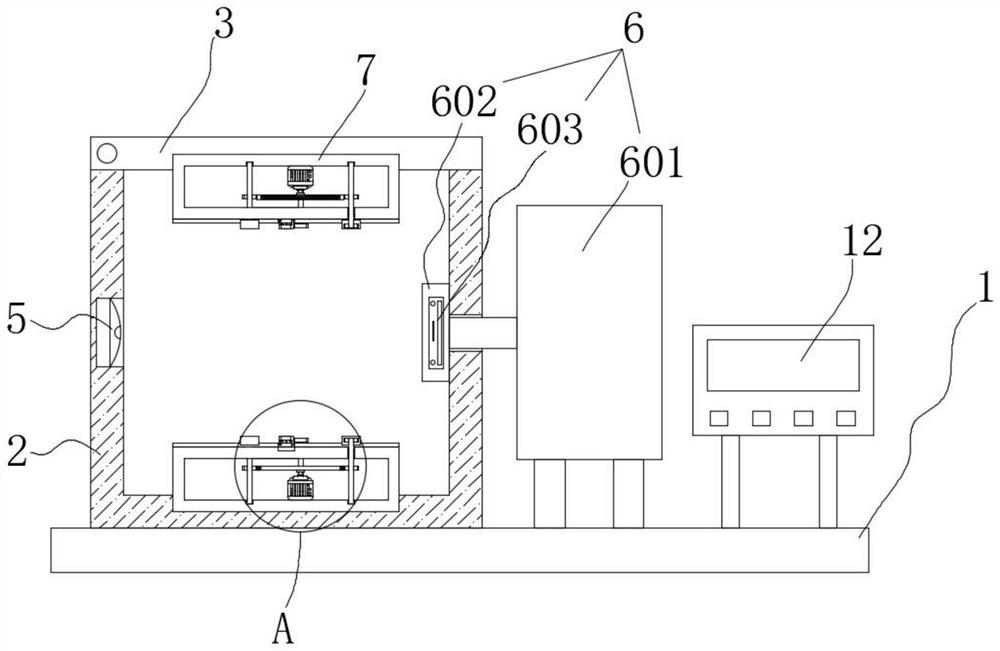

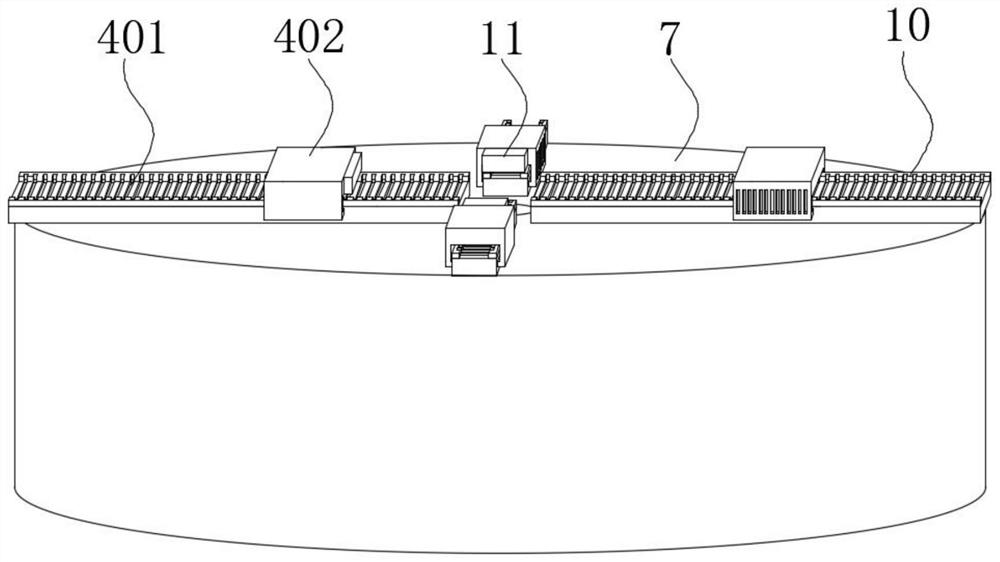

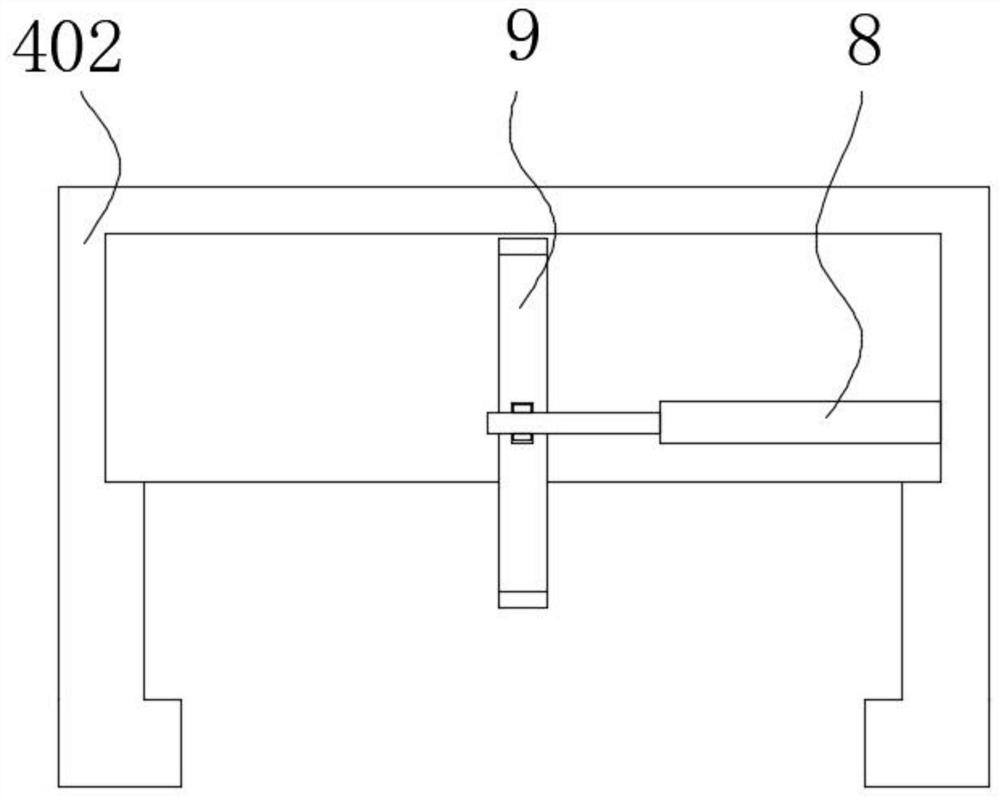

[0031] see Figure 1~4 , in the present invention, a kind of reducer rigidity detection device comprises base plate 1, and the top of base plate 1 is fixedly connected with detection box 2, and the top of detection box 2 is hinged with cover 3, and the bottom of cover 3 and the inside of detection box 2 Both are provided with a clamping assembly 4 , a laser ranging sensor 5 is fixedly installed on the left side inside the detection box 2 , and a detection assembly 6 is fixedly installed on the top of the bottom plate 1 .

[0032] In the present invention, the arrangement of the bottom plate 1 facilitates the support of the whole device. When the user needs to check the rigidity of the main shaft of the reducer, the cover 3 can be opened, and then one end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com