Thick food temperature adjusting machine

A food and viscous technology, which is applied in the field of quantitative pouring machines for viscous food, can solve problems such as inappropriateness, increased manual processing costs, uncontrollable sprue flow, etc., and achieves the effect of not being prone to errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

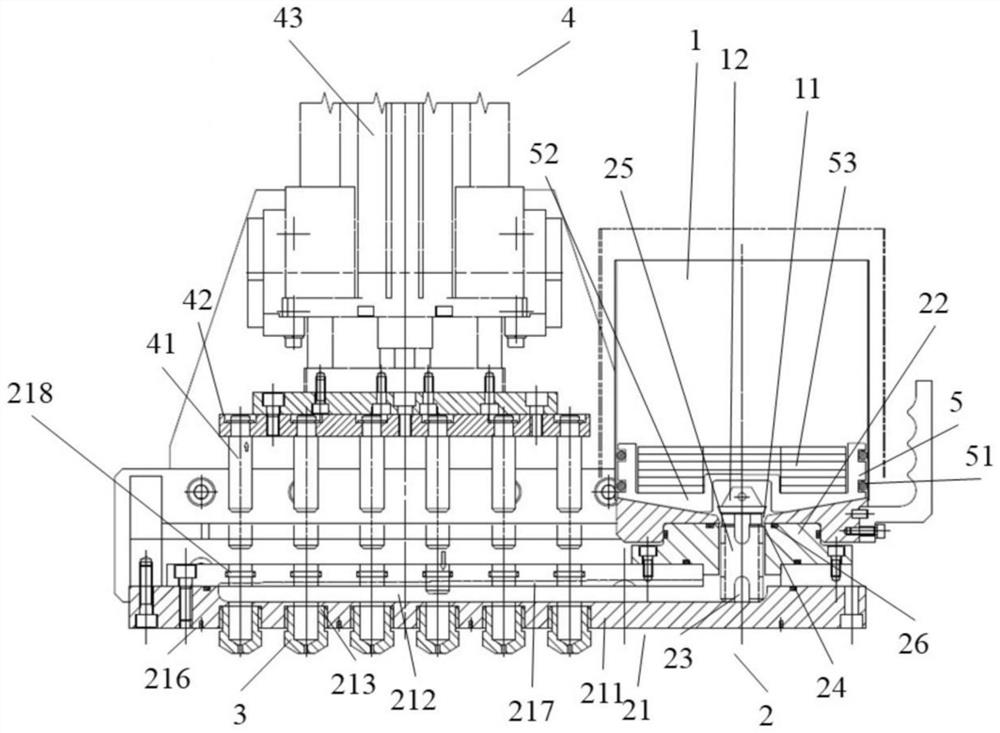

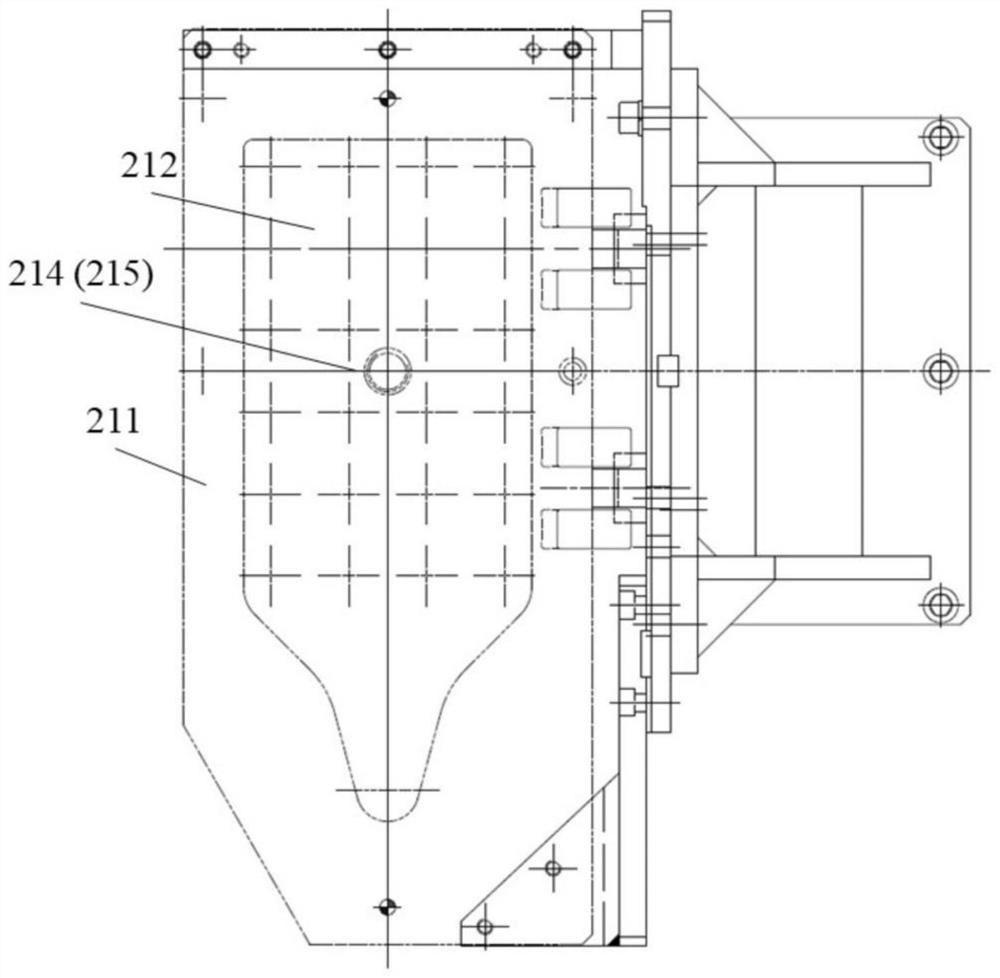

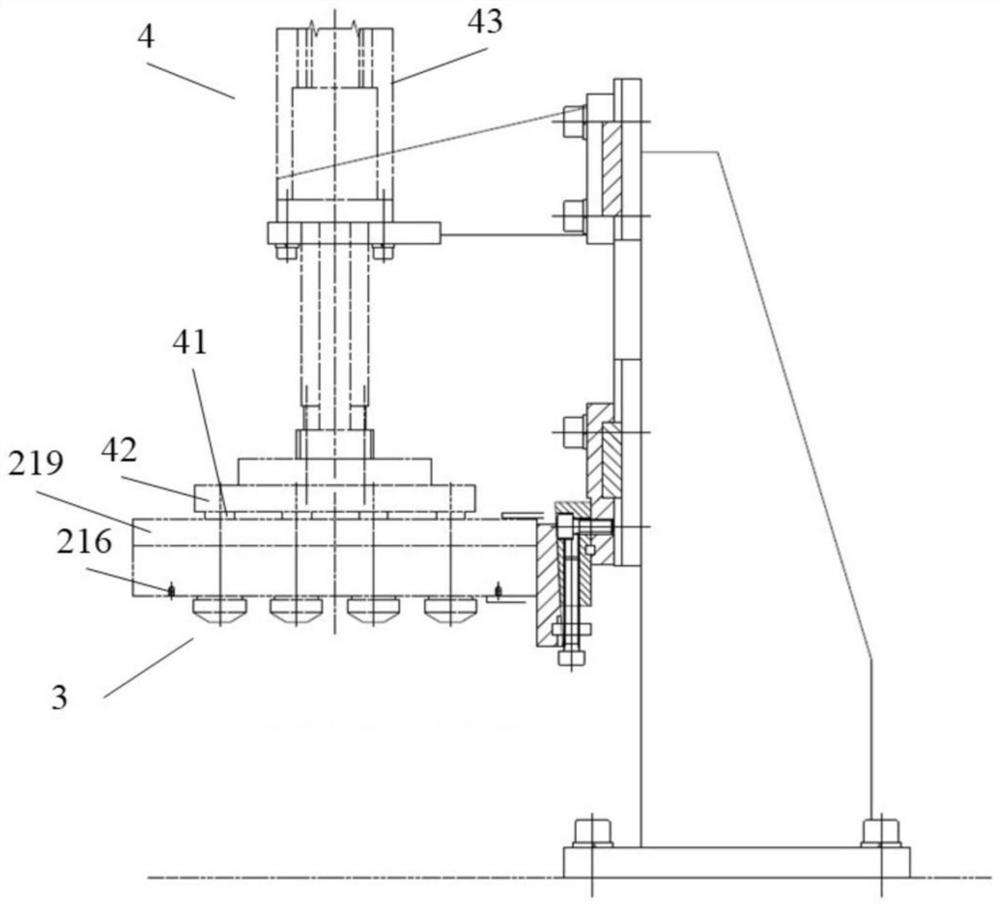

[0063] see figure 1 As shown, the present invention is about a viscous food quantitative pouring machine. The structure of the present invention is first introduced below, and then the action flow of the present invention is introduced. First, the structure of the present invention includes:

[0064] One container 1:

[0065] see figure 1 As shown, the container 1 is used for containing viscous food. For example, those whose raw materials are thick, such as chocolate, are all viscous foods referred to in this manual, and the bottom of the container 1 is provided with an opening. 11 for outputting the viscous food.

[0066] In order to allow the viscous food to slide out of the opening 11 automatically, the bottom wall of the container 1 slopes downward toward the opening 11, so that as long as the opening 11 is open, the The viscous food in the container 1 will automatically fall out from the opening 11 . In order to make the opening 11 appear in a closed state, the openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com