Smoke removal device of denim laser washing device

A water washing device and denim technology, applied in laser welding equipment, dispersed particle separation, manufacturing tools, etc., can solve the problems that activated carbon particles cannot be fully used, cannot meet the production needs of denim, and the replacement of activated carbon particles is inconvenient, etc., to achieve protection The effect of environment and staff, simple structure and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

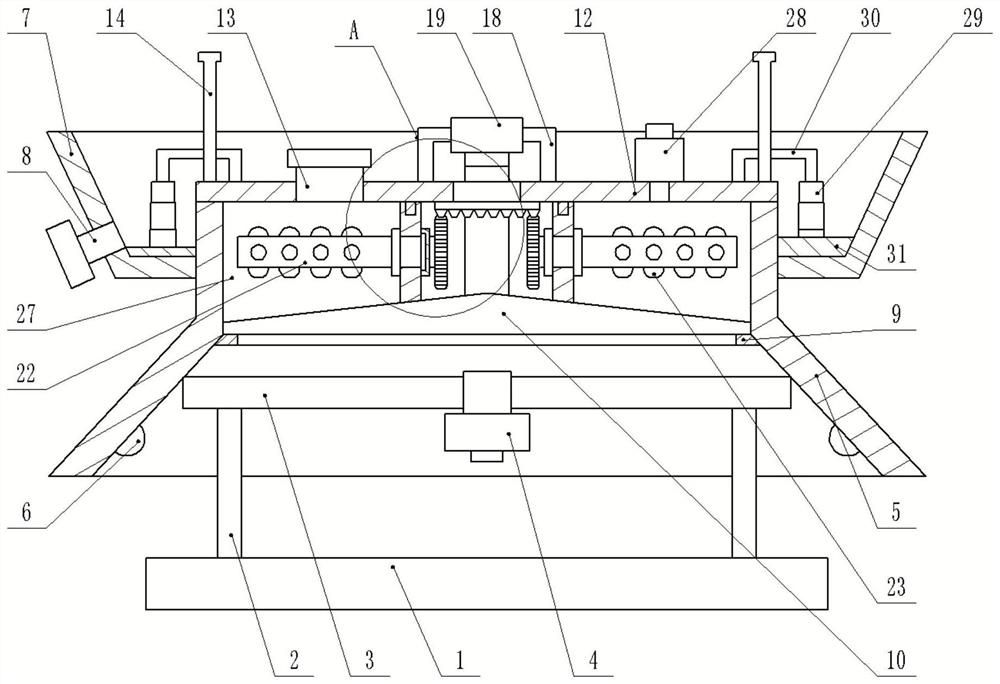

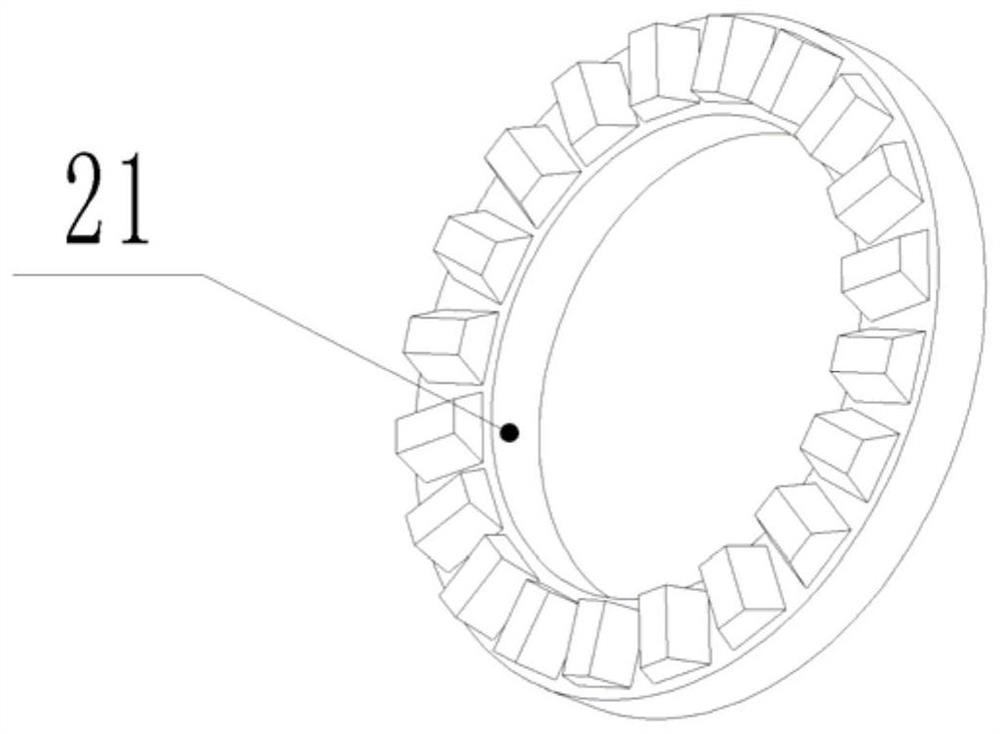

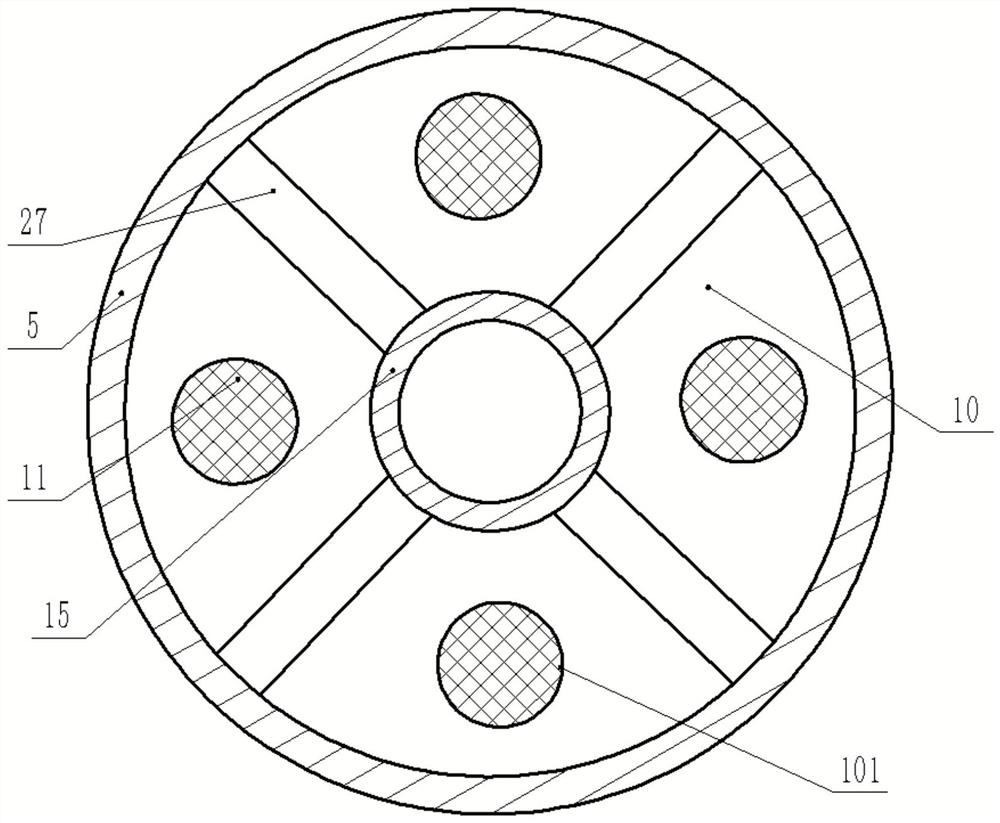

[0023] Such as Figure 1 to Figure 5As shown, a smoke removal device for a denim laser washing device includes a workbench 1, a plurality of vertical rods 2 are fixedly connected to the top surface of the workbench 1, and slide rails 3 are fixedly connected to the top surface of the plurality of vertical rods 2, A laser marking device 4 is movably connected to the slide rail 3, and a first cylinder 5 is fixedly connected to the top surface of the slide rail 3. The shape of the first cylinder 5 is funnel-shaped, and the first cylinder 5 A plurality of LED lamps 6 are fixedly connected in a ring on the inner wall, and the LED lamps 6 are electrically connected to an external controller through a circuit. The top gradually becomes larger, the side wall of the barrel body 7 is fixedly connected with a discharge pipe 8, the discharge pipe 8 is arranged obliquely, and the bottom of the discharge pipe 8 is threadedly connected with a cover body, and the inside of the barrel body 7 T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com