External ink supply integrated device

A technology of integrated device and ink supply device, applied in printing and other directions, can solve the problems of high technical level requirements of operators, long recovery time of negative pressure module, low adjustment efficiency of reset negative pressure value, etc., and meet the technical level requirements. Low, saving transportation cost, the effect of minimizing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

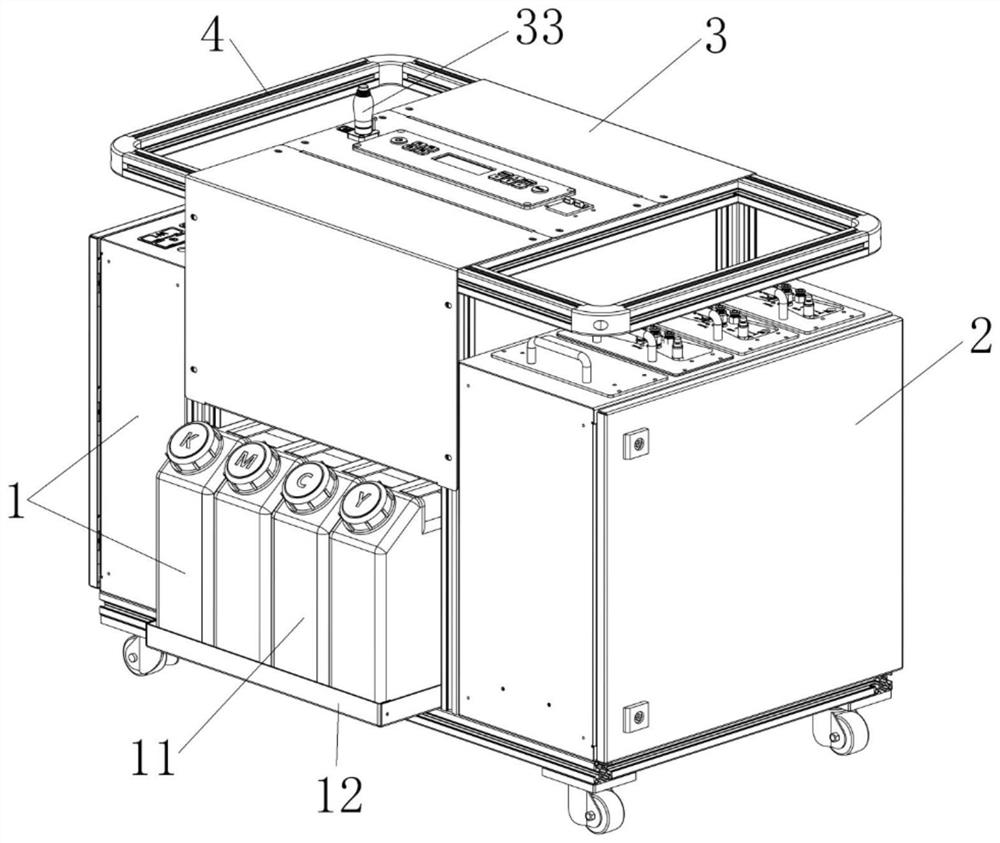

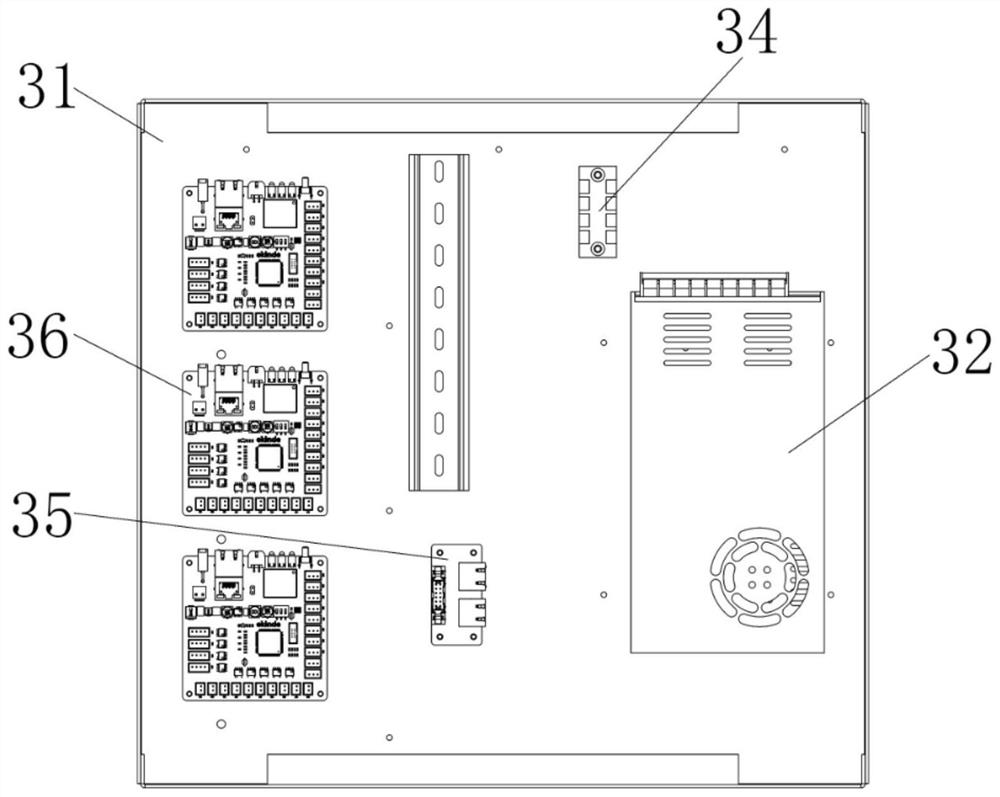

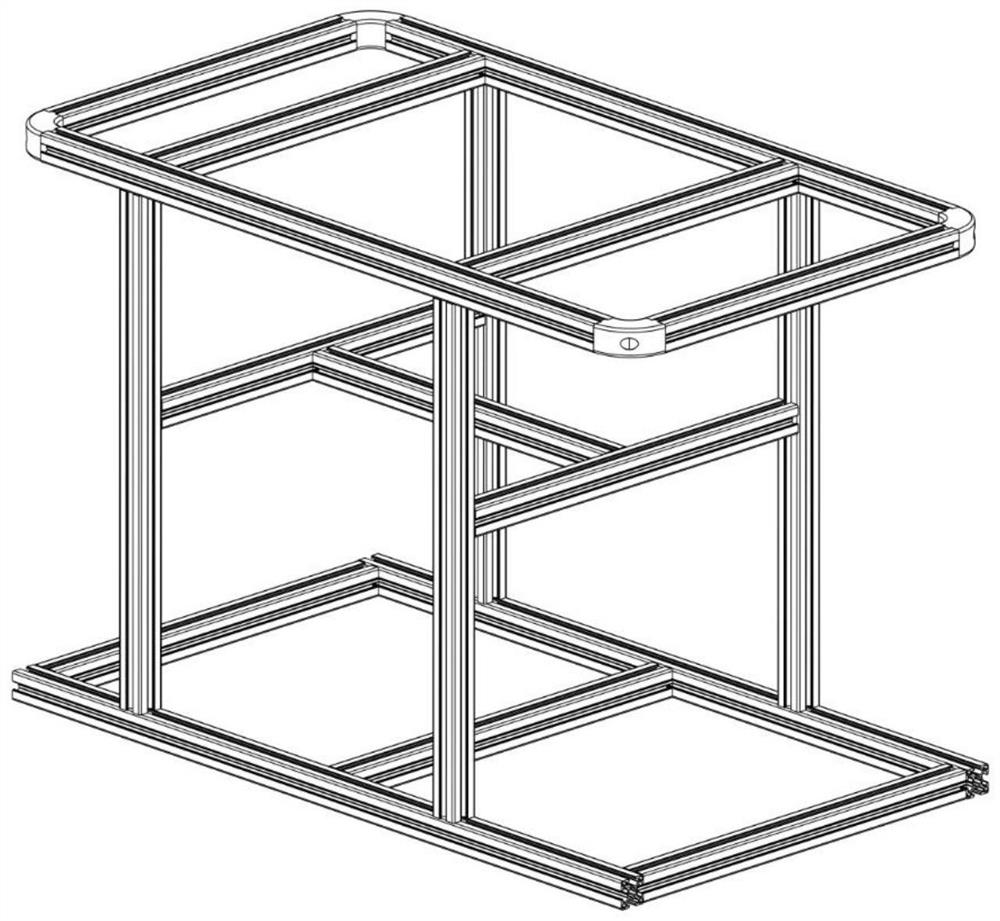

[0046] refer to figure 1 and figure 2 As shown, an external ink supply integrated device is improved in that: it includes an ink supply device 1, which is used to continuously supply ink to the print head; it includes a negative pressure device 2, and the negative pressure device 2. It is used to adjust the negative pressure value in each ink chamber of the secondary ink box connected to the printing nozzle; it includes an electric control device 3, and the electric control device 3 includes a power supply device, a control device and an interface assembly, and the power supply devices are respectively Connected with the ink supply device 1, the negative pressure device 2 and the control device and supply power to them, the control device is used to control the operation of the ink supply device 1 and the negative pressure device 2, the The interface assembly includes an aviation plug 33 through which the control device is connected to the printer bus.

[0047] In this embo...

Embodiment 2

[0053] On the basis of embodiment 1, with reference to Figure 4 As shown, the ink supply device 1 includes several ink supply components, and the ink supply components include a main ink tank 11 , an ink pump 14 , a filter 15 , and a solenoid valve 17 connected in sequence.

[0054] Further, the ink supply device 1 includes an ink tank tray 12 installed under the middle part of the installation frame 4 , and the main ink tank 11 is arranged in the ink tank tray 12 .

[0055] Further, the ink supply device 1 includes an ink tank 13 installed on one side of the installation frame 4 , and the ink pump 14 , filter 15 , and electromagnetic valve 17 are installed in the ink tank 13 .

[0056] In this embodiment, the ink flows out of the main ink tank 11 driven by the ink pump 14, and flows into the filter 15 through the ink pump 14. The filter 15 is used to filter out the particles in the ink to avoid clogging the pipeline or the print head. The filtered ink flows through the sole...

Embodiment 3

[0058] On the basis of embodiment 1 or 2, with reference to Figure 5 to Figure 7 As shown, the negative pressure device 2 includes a negative pressure box 21 and a number of negative pressure modules 22 installed in the negative pressure box 21, one end of the negative pressure module 22 is equipped with a push-in connector 2292, the negative pressure The bottom of the box 21 is provided with a support plate 24 vertically installed with the negative pressure module 22 , and the support plate 24 is provided with a plurality of quick-plug joint adapter plates 25 matching the quick-plug joints 2292 .

[0059] In this embodiment, the negative pressure module 22 in the negative pressure device 2 is installed in a drawer type, and the quick-plug connector adapter plate 25 has the functions of communication and power supply at the same time, and transmits information with the negative pressure module 22 through the quick-plug connector 2292 and compares them. power supply. During u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com