Preparation method of high-breakdown and high-dielectric FPE-based composite material film

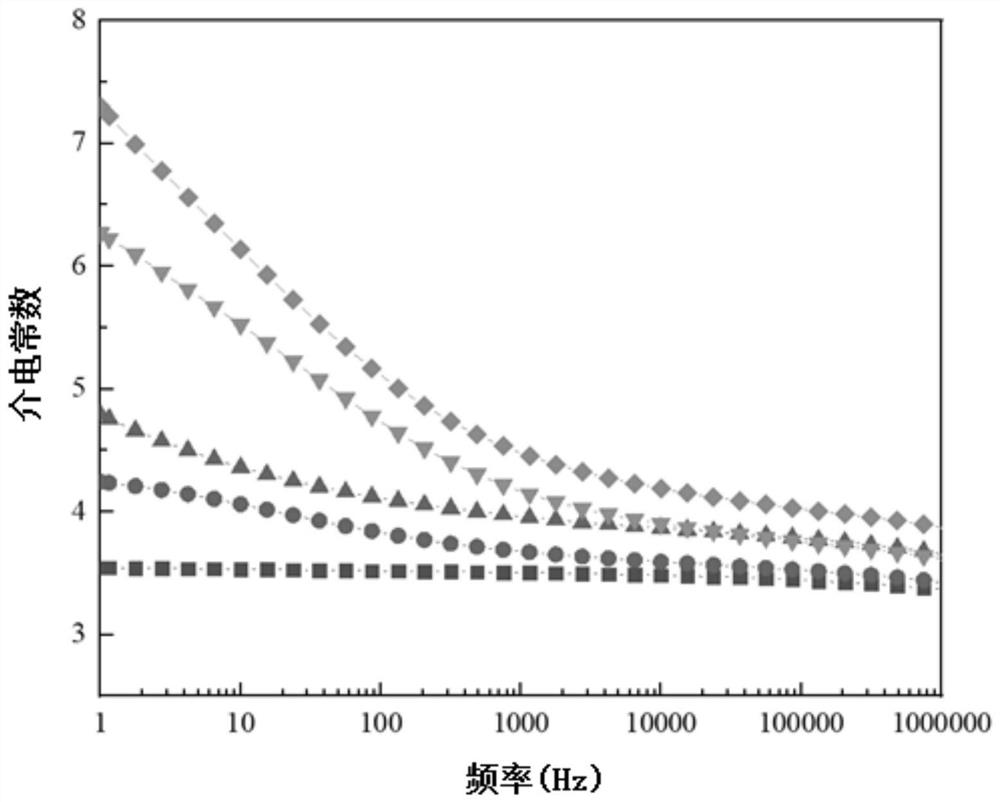

A composite material film and high dielectric technology, which is applied in the field of preparation of FPE-based composite material film, can solve the problems of increased conductivity and dielectric loss of composite film, and achieve the improvement of dielectric properties, excellent dielectric properties, and preparation process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

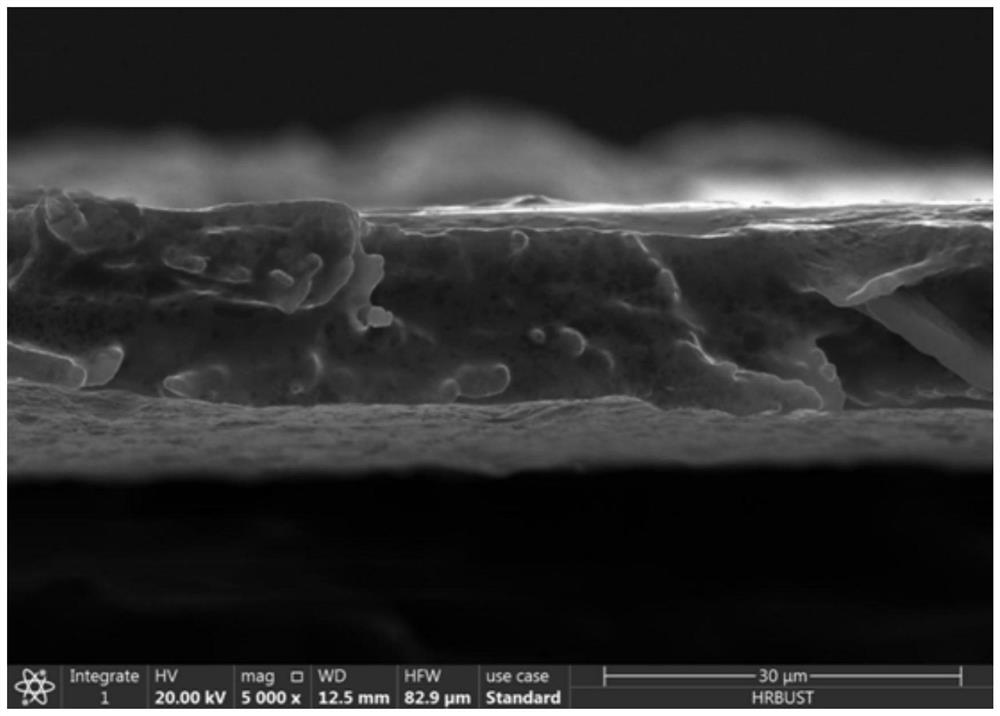

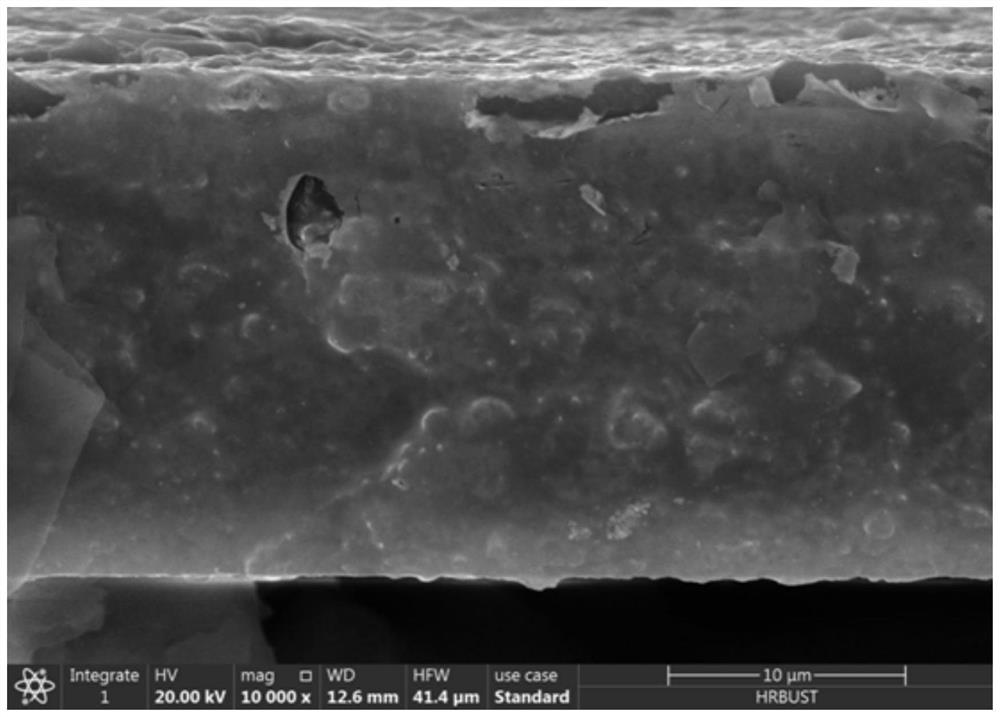

[0018] Specific embodiment one: the preparation method of a kind of high breakdown and high dielectric FPE-based composite film of this embodiment is carried out according to the following steps:

[0019] adding the hexagonal boron nitride nanosheets into the methylpyrrolidone solution, and ultrasonically dispersing for 40 to 120 minutes to obtain a mixed solution a, wherein the mass fraction of the hexagonal boron nitride nanosheets in the mixed solution a is 5% to 20%; SiO was added to solution a 2 Particles are ultrasonically dispersed for 40 to 120 minutes to obtain a mixed solution b in which SiO 2 The mass fraction of the particles is 3% to 9%; while stirring, the fluorene polyester particles are added to the mixed solution b, and stirred for 1 to 2 hours to obtain the stirred mixed solution b. The volume of the methylpyrrolidone solution is the same as The mass ratio of fluorene polyester particles is (3.5~4)mL:(0.4~0.6)g; evenly coat the stirred mixed solution b on on...

specific Embodiment approach 2

[0023] Embodiment 2: This embodiment differs from Embodiment 1 in that: the mass fraction of hexagonal boron nitride nanosheets in the mixed solution a is 5%, 10%, 15% or 20%.

[0024] Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0025] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: SiO in the mixed solution b 2 The mass fraction of particles is 3%, 5%, 7% or 9%.

[0026] Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com