Supporting seat for improving looseness of titanium lump of titanium sponge

A technology of sponge titanium and porosity, which is applied in the field of non-ferrous metal smelting, can solve problems such as electrode breaking or slag falling, abnormal smelting, and affecting the yield of piezoelectric electrodes, etc., and achieve the effect of increasing the barrel density and promoting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the drawings and embodiments, but it is not used as a basis for any limitation on the invention.

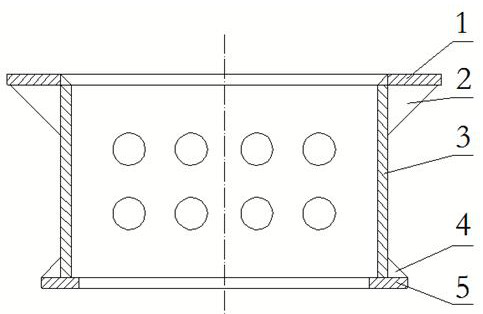

[0016] As shown in the accompanying drawings, a support base for improving the porosity of titanium sponge, including an annular upper flange ring 1 and a lower flange ring 5 and a cylindrical support 3, the upper port and the lower end of the support 3 The ports are all open, the upper port of the support tube 3 is welded to the inner edge of the upper flange ring 1, the end face of the lower port of the support tube 3 is welded to the upper surface of the lower flange ring 5, in order to avoid the upper flange ring 1, The lower flange ring 5 and the support tube 3 are deformed during use, and a rib plate is also provided, including the upper rib plate 2 arranged between the upper flange ring 1 and the outer wall of the support tube 3 and the upper rib plate 2 arranged between the lower fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com