A support seat for improving the porosity of titanium sponge

A technology of sponge titanium and porosity, applied in the field of non-ferrous metal smelting, can solve the problems of electrode disconnection or slag loss, abnormal smelting, interruption, etc., to achieve the effect of promoting growth and increasing barrel density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is further described in detail below in conjunction with the accompanying drawings and embodiments, but is not used as a basis for any limitation of the invention.

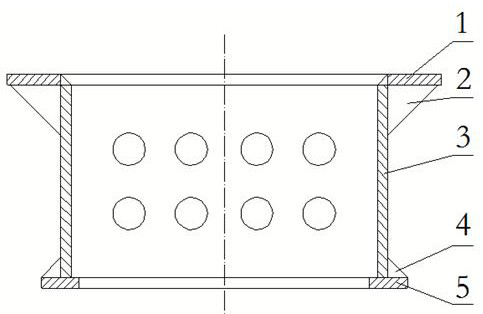

[0016] Referring to the accompanying drawings, a support seat for improving the porosity of sponge titanium and titanium lumps includes an annular upper flange ring 1 and a lower flange ring 5 and a cylindrical support cylinder 3, the upper port of the support cylinder 3 and the lower flange ring 5. The ports are all open, the upper port of the support cylinder 3 is welded with the inner edge of the upper flange ring 1, the end face of the lower port of the support cylinder 3 is welded with the upper surface of the lower flange ring 5, in order to avoid the upper flange ring 1, The lower flange ring 5 and the support cylinder 3 are deformed in use, and are also provided with reinforcing rib plates, including the upper rib plate 2 arranged between the upper flange ring 1 and the outer wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com