Tension locking device

A technology of lockers, pulls, applied in the direction of sheet pile walls, protection devices, building construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

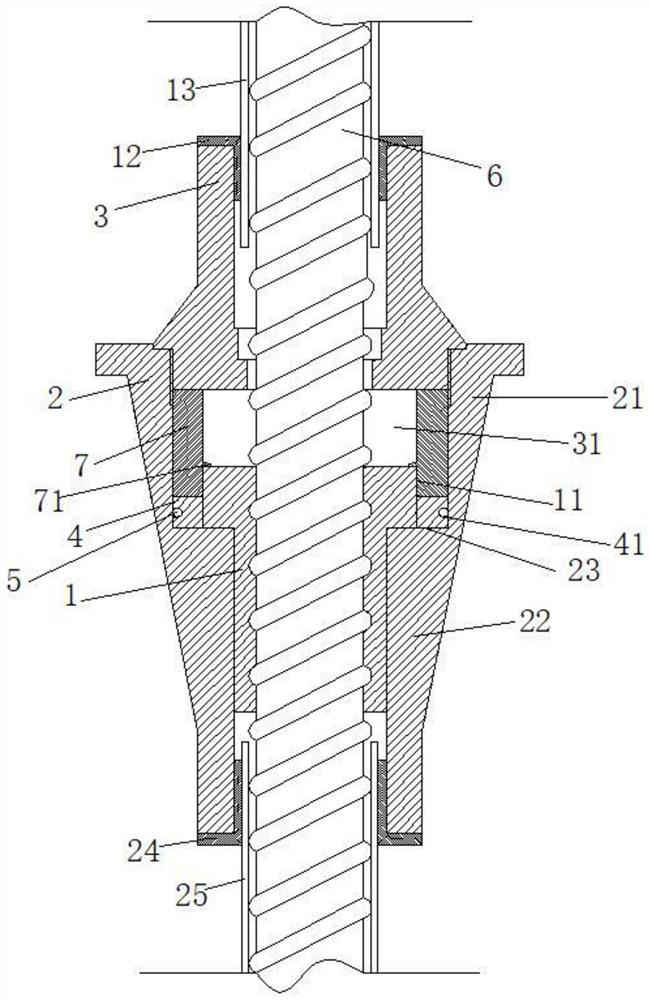

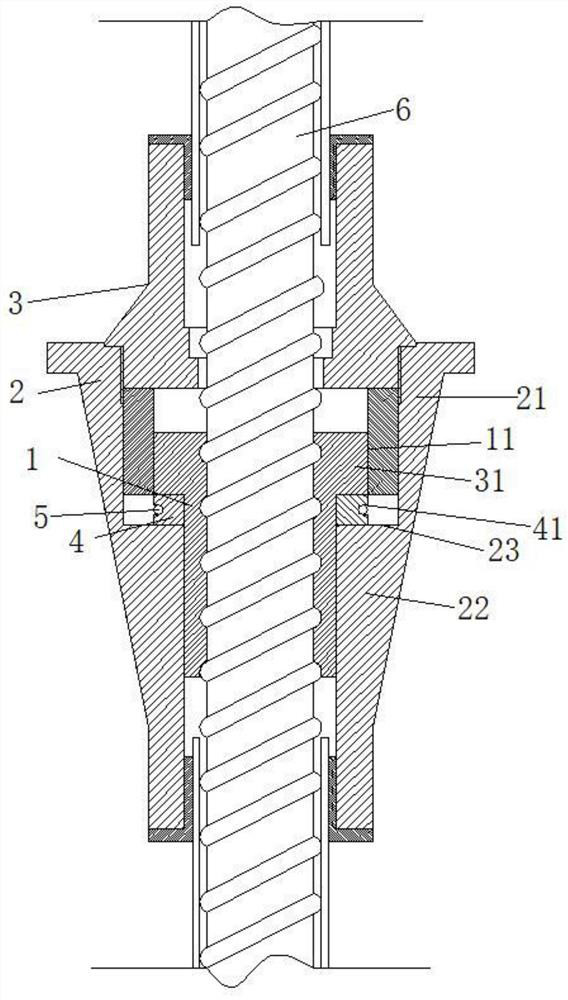

[0024] Such as figure 1 The tension locker shown includes a sleeve 1, a bearing sleeve 2, a gland 3, a slider 4, and a rubber ring 5;

[0025] The sleeve 1 is threaded on the peripheral surface of the finish-rolled rebar 6; one end of the sleeve 1 extends radially away from the finish-rolled rebar 6 with a ring eaves 11 integrally;

[0026] The gland 3 is positioned above the sleeve 1 and is installed on the peripheral surface of the finish-rolled threaded steel bar 6 through the first sealing cover 12 and the first sleeve 13; the first sealing cover 12 and the The upper end of the gland 3 is threaded, and the first sleeve 13 is sleeved on the outer surface of the finish-rolled threaded steel bar 6 .

[0027] A movable space 31 for the movement of the sleeve 1 is provided between the gland 3 and the sleeve 1;

[0028] Such as figure 1 As shown, in the initial state, the slider 4 is fixed outside the ring eaves 11 of the sleeve 1;

[0029] Preferably, the carrying sleeve 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com