A method and fiber for preparing ultra-high molecular weight polyethylene fiber

An ultra-high molecular weight, polyethylene fiber technology, applied in the direction of single-component polyolefin rayon filament, fiber processing, complete sets of equipment for the production of rayon, etc., can solve problems affecting fiber quality and production efficiency, adverse solvent diffusion and volatilization, Increase the cost of solvent recovery and other issues, to achieve the effect of reducing the production rate of filaments and the rate of broken ends, low cost, and enhanced cohesion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

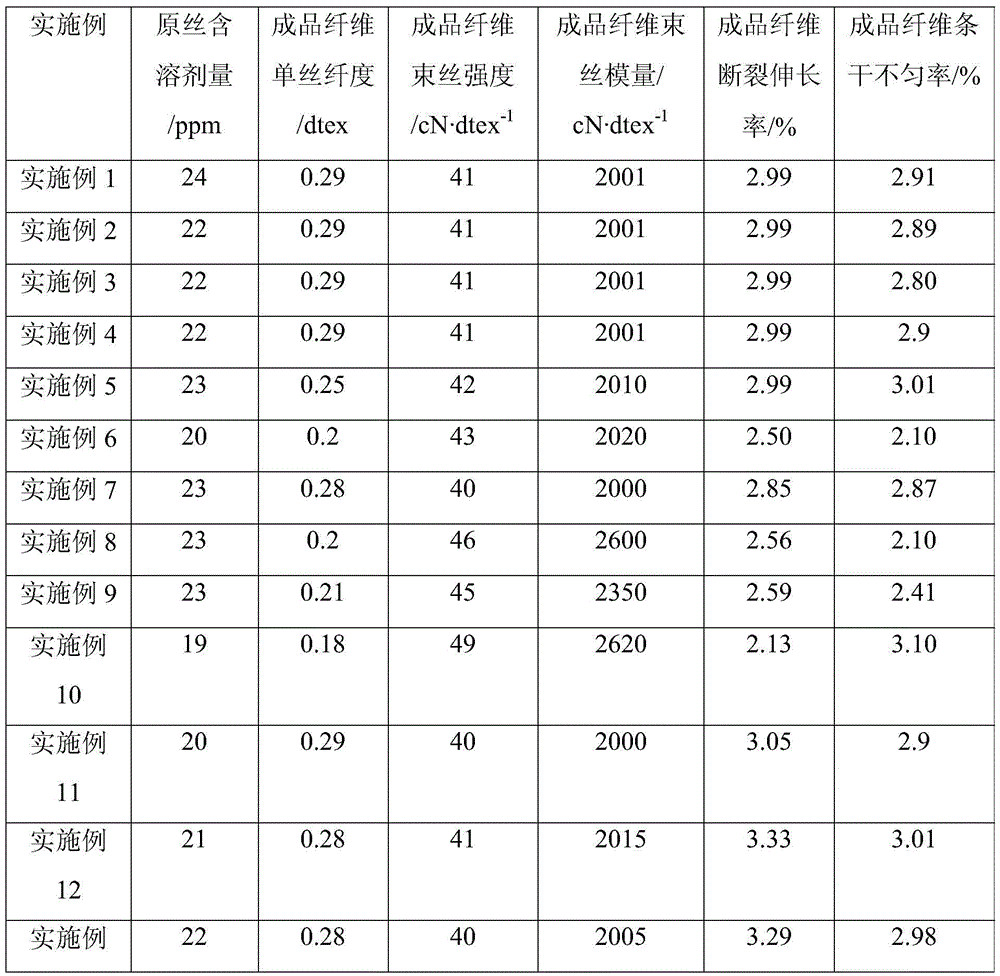

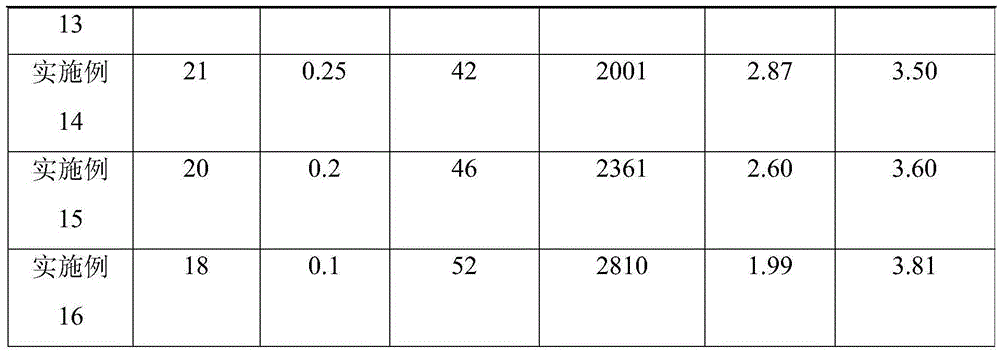

Examples

Embodiment 1

[0061] 7% (mass percentage) of ultra-high molecular weight polyethylene (viscosity-average molecular weight 6,000,000) decahydronaphthalene solution is extruded through the spinneret in the spinning box, and through the gas phase section, the spinneret plate surface area is 50.24cm 2 , the cross-sectional area of the gas-phase section is 1.1 times the area of the spinneret plate, the length of the gas-phase section is 0.2 of the cross-sectional width of the sealing cover, that is, 17mm, nitrogen enters through the air inlet, and the temperature in the sealing cover is 99 ° C, nitrogen and flash The steamed decahydronaphthalene is drawn out from the air suction port, and the fine spinning flow enters the box containing pure water at 10°C. The tensile stress is 8kPa. The spun filaments pass through five sets of pressing rollers. The force exerted by each set of pressing rollers on the spun filaments is 0.5MPa. The bonding rate of the filaments is 5%. Winding, and finally pos...

Embodiment 2

[0063] 7% (mass percentage) of ultra-high molecular weight polyethylene (viscosity-average molecular weight 6,000,000) decahydronaphthalene solution is extruded through the spinneret in the spinning box, and through the gas phase section, the spinneret plate surface area is 50.24cm 2 , the cross-sectional area of the gas-phase section is twice the area of the spinneret plate, the length of the gas-phase section is 0.8 of the cross-sectional width of the sealing cover, that is, 91mm, nitrogen enters through the air inlet, and the temperature in the sealing cover is 150 ° C. The steamed decahydronaphthalene was drawn out from the air suction port, and the other processes were the same as in Example 1. The final fiber performance indicators obtained by post-spinning and drawing are shown in Table 1.

Embodiment 3

[0065] 7% (mass percentage) of ultra-high molecular weight polyethylene (viscosity average molecular weight 6 million) decahydronaphthalene solution is extruded through the spinneret in the spinning box body, and through the gas phase section, the spinneret plate surface area is 200.96cm 2 , the cross-sectional area of the gas phase section is 4 times the area of the spinneret plate, the length of the gas phase section is 1 time the cross-sectional width of the sealing cover, that is, 320mm, nitrogen enters through the air inlet, the temperature in the sealing cover is 220 ° C, nitrogen and The flash evaporated decahydronaphthalene is drawn out from the air suction port, and the spinning fine stream enters the box containing -10°C decahydronaphthalene. The other processes are the same as in Example 1. The final fiber performance indicators obtained after post-spinning and drafting are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile stress | aaaaa | aaaaa |

| tensile stress | aaaaa | aaaaa |

| tensile stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com