Method for preparing silicon germanium on insulator (SGOI) by layer transfer technology

A technology of multi-layer materials and epitaxial materials, which is applied in the field of preparing silicon-germanium-on-insulator and using layer transfer technology to prepare silicon-germanium-on-insulator materials, which can solve the problems of inability to prepare high-speed materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

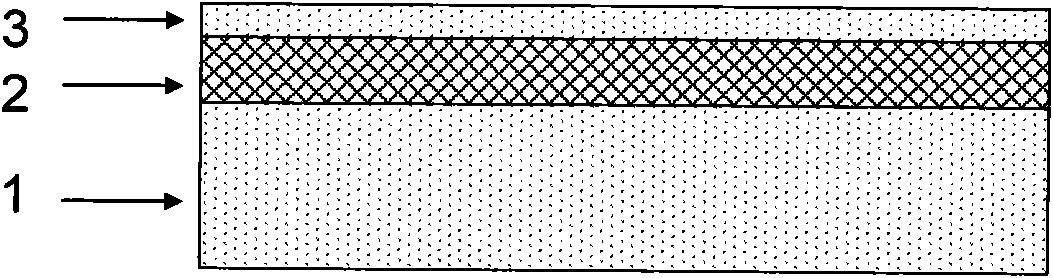

[0017] 1. Use chemical vapor deposition method to epitaxial Si sequentially on bulk silicon substrate 1-x Ge x , Si epi Two different films, where 01-x Ge x The thickness of the film is smaller than the critical thickness while ensuring the Si epi Thicker than Si 1-x Ge x Thickness (see attachment figure 1 ).

[0018] 2. Take a piece of silicon substrate material and prepare SiO on the surface of the silicon substrate by thermal oxidation, or plasma enhanced chemical vapor deposition (PECVD), or other methods 2 , SiO 2 The thickness is generally 200nm~1um.

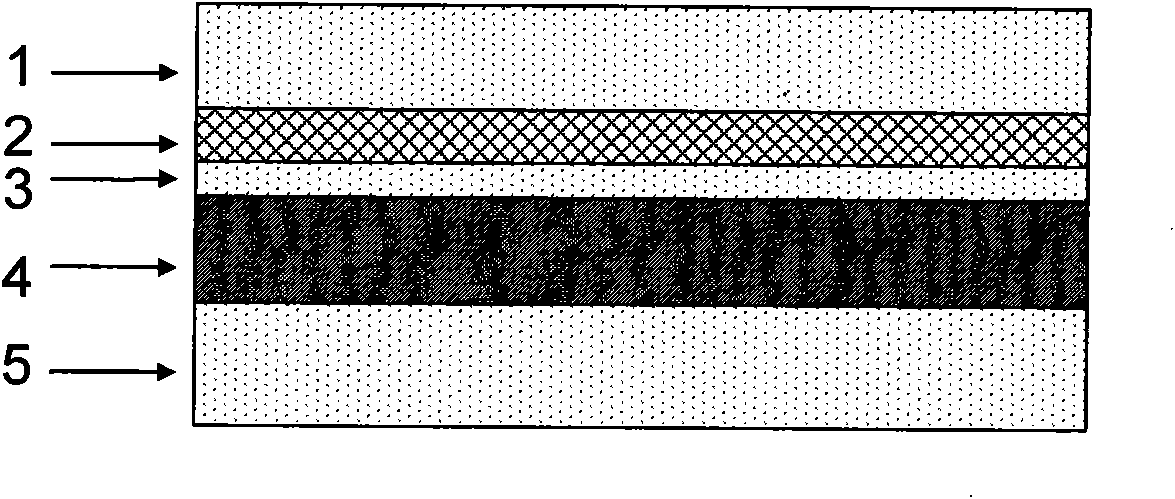

[0019] 3. Bond the material prepared in step 1 with the material prepared in step 2 (see attached figure 2 ).

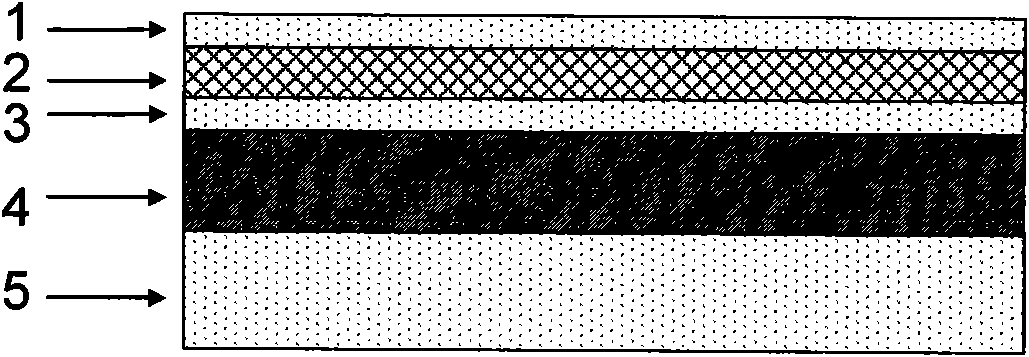

[0020] 4. Through the grinding method, the material obtained in step 3 is removed and Si 1-x Ge x Most of the adjacent bulk Si (see attached image 3 ).

[0021] 5. A chemical solution with a high Si:SiGe etching ratio including TMAH (tetramethyl ammonium hydroxide) or KOH chemical solution is used as a selective etchin...

Embodiment 2

[0025] 1. Use chemical vapor deposition method to epitaxial Si sequentially on bulk silicon substrate 1-x Ge x , Si epi Two different films, where 01-x Ge x The thickness of the film is smaller than the critical thickness while ensuring the Si epi Thicker than Si 1-x Ge x Thickness (see attachment figure 1 ).

[0026] 2. Put H + Or He + 5×10 16 cm -2 ~1×10 17 cm -2 Choose the appropriate energy, and inject from the upper surface of the material prepared in step 1 into the silicon substrate layer of the epitaxial material close to Si 1-x Ge x Place of film (see attached Image 6 ), the preferred recommended dose is 6×10 16 cm -2 , The preferred implantation ion is H + .

[0027] 3. Take a piece of new silicon substrate material and prepare SiO on the surface of the silicon substrate by thermal oxidation, or plasma enhanced chemical vapor deposition (PECVD), or other methods 2 , SiO 2 The thickness is generally 200nm~1um.

[0028] 4. Bond the material prepared in step 2 with the materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com