TPO waterproof roll non-perforation fixing method

A technology of waterproof roll material and fixing method, which is applied to roofs, roofs, and building structures using flexible materials. It can solve problems such as difficult leakage prevention repairs, high maintenance costs, and factory building leakage, and achieve economic benefits and social benefits. Significant benefit, low maintenance rate and low leakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The non-perforated fixing method of the TPO waterproof membrane of the present invention:

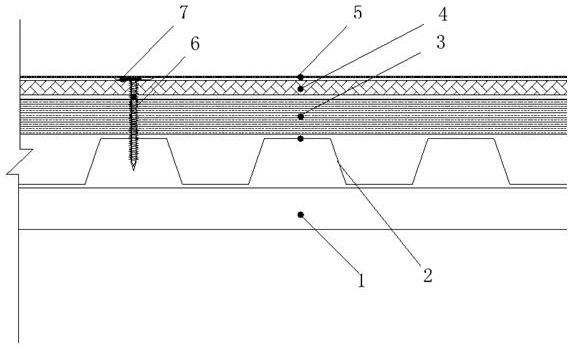

[0020] see now figure 1 , figure 1 It is a schematic diagram of the non-perforated fixing structure of the roof TPO waterproof membrane according to the embodiment of the present invention. As shown in the figure, the non-perforated fixed structure of the TPO waterproof membrane includes a 0.8mm thick circular fixed steel plate 7; 7φ4mm*120mm screw 6 (diameter*length); roof purlin 1; 0.8mm thick profiled steel plate 2; 80mm thick Extruded board 3; 10mm thick calcium silicate fireproof board 4; 1.5mm thick TPO waterproof membrane 5.

[0021] figure 2 It is a structural schematic diagram of a circular fixed steel plate in an embodiment of the present invention. The 0.8mm thick circular fixed steel plate is used together with the φ4mm*120mm screw, and the 0.8mm thick profiled steel plate, 80mm thick extruded plastic plate, and 10mm thick calcium silicate fireproof board are fix...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap