Blade tenon coating layer thickness measuring device and use method thereof

A technology of coating thickness and blade tenon, which is applied in the field of blade tenon coating thickness measurement device, can solve the problems such as the undetectable coating of dovetail blade tenon, and achieve the effects of simple and easy operation, low detection cost and improved detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

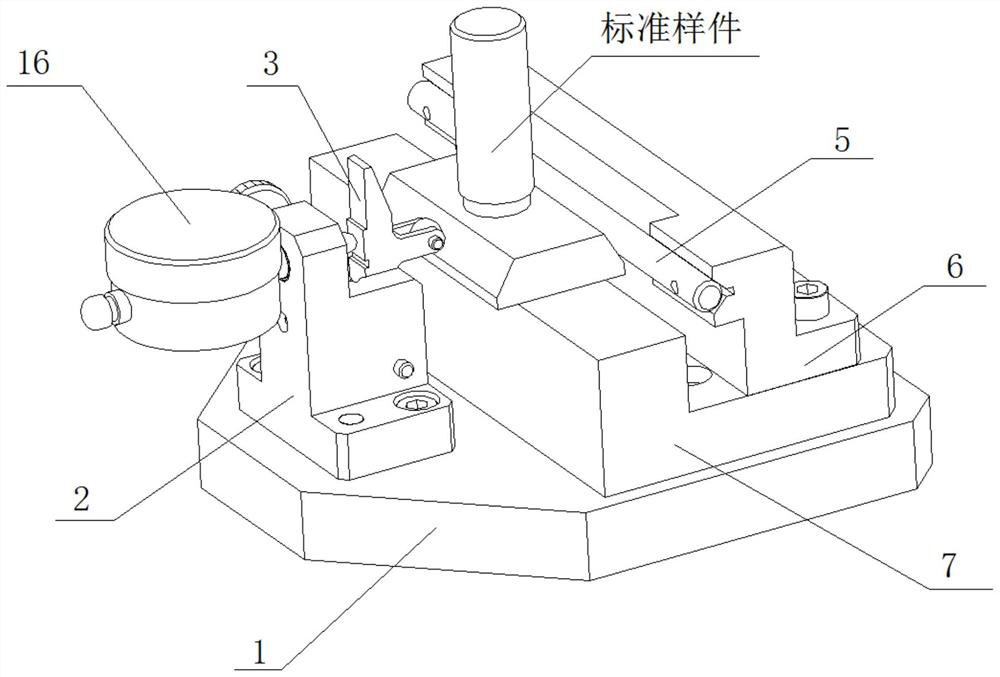

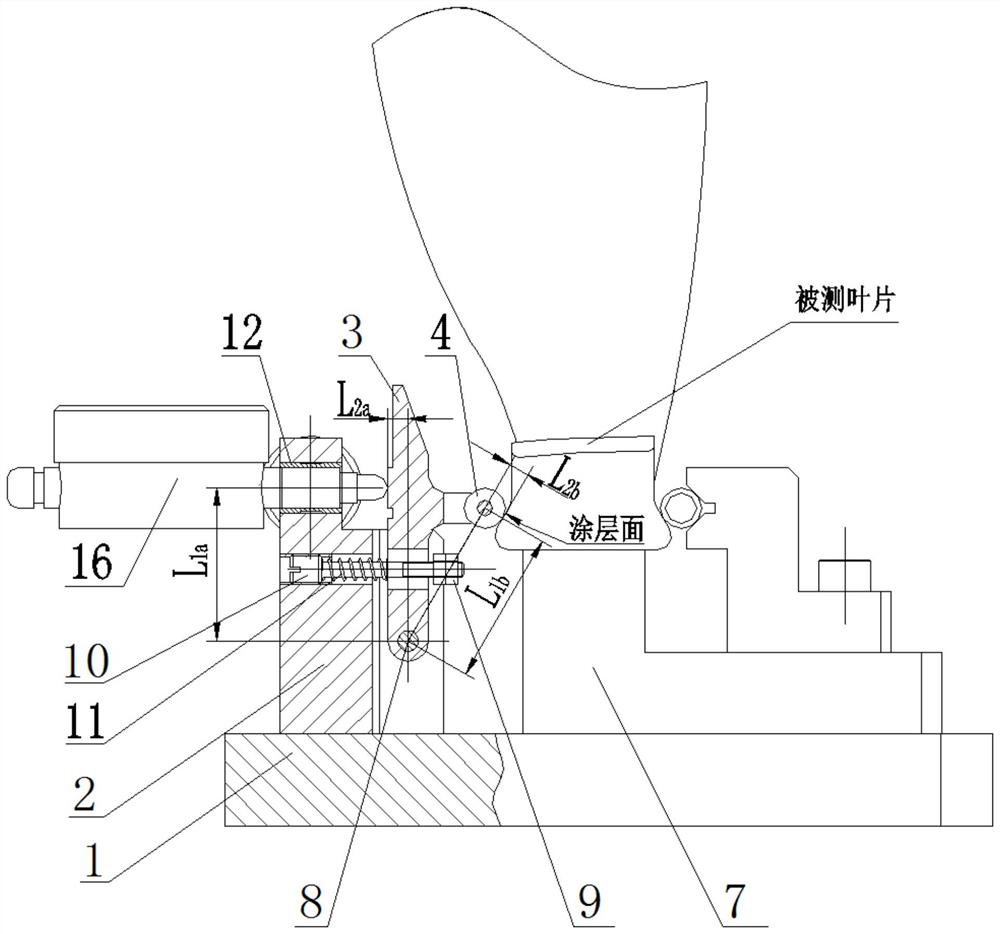

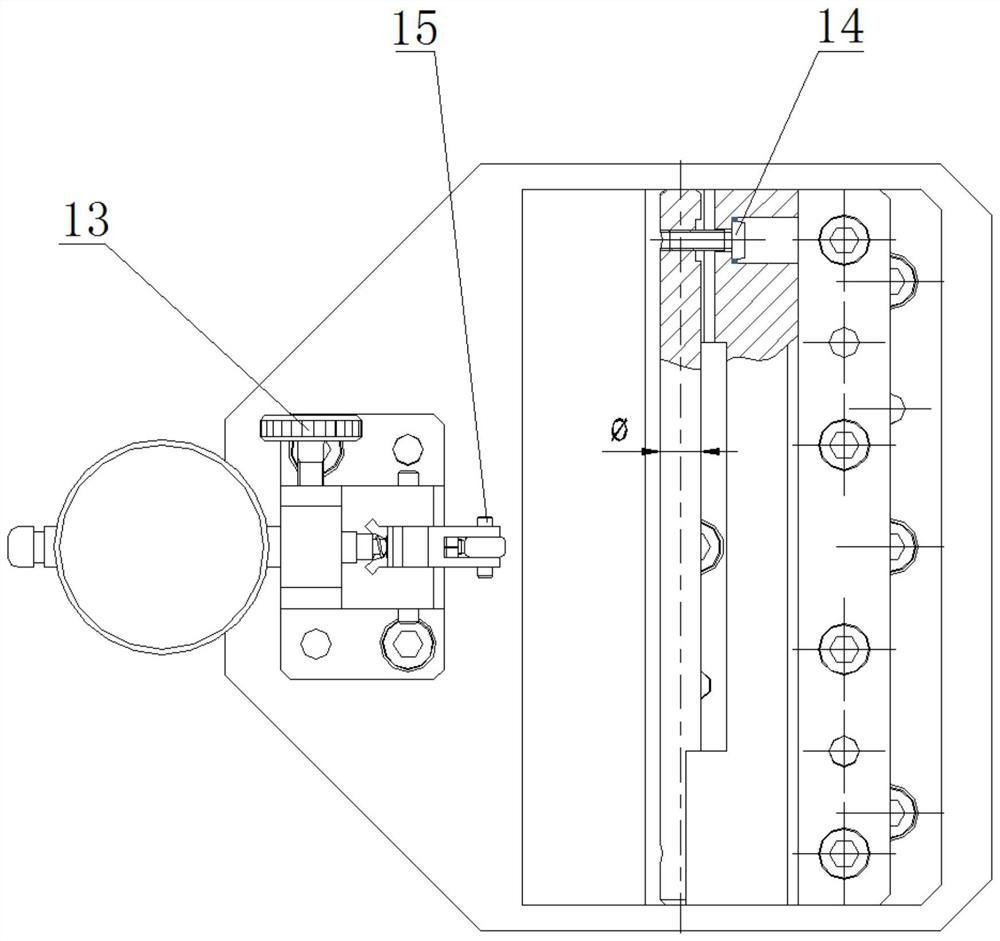

[0017] Such as Figure 1 to Figure 3 As shown, a blade tenon coating thickness measuring device includes a base plate 1, a screw II14, a support I2, a Z-shaped support II6 and a base 7 with a boss, and the upper surface of the base plate 1 is installed by bolts There are support I2 and base 7, and the center line of symmetry of support I2 is coplanar with the center line of symmetry of base 7. The base 7 is provided with support II6, and the horizontal part of the lower part of support II6 is in the same plane as base 7. Through bolt connection, the side wall of the upper horizontal part of the support II6 is provided with a horizontal V-shaped groove on the side close to the support I2, and a positioning rod 5 is installed in the V-shaped groove, and the other end of the upper horizontal part of the support II6 is opened. There is a counters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com