Self-lubricating knuckle bearing accelerated degradation reliability evaluation and service life prediction method

A joint bearing and accelerated degradation technology, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve the problems of low evaluation accuracy, ignore performance degradation data correlation, and unrealistic problems, and achieve the goal of improving evaluation accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

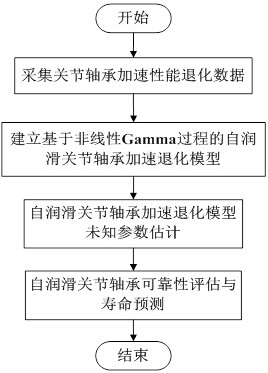

[0107] The present invention provides a self-lubricating joint bearing accelerated performance degradation reliability assessment and life prediction method, the flow chart is as follows figure 1 Shown, the concrete realization of the inventive method comprises the following steps:

[0108] S1: Collect the degradation data of the joint bearing acceleration performance;

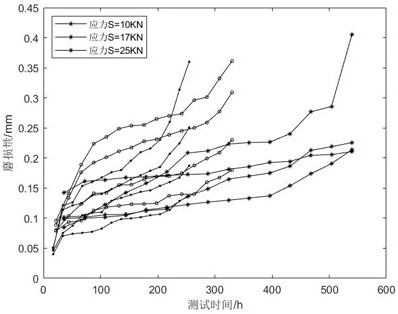

[0109] Suppose there is a batch of self-lubricating spherical plain bearings of the same type at Q accelerated stress levels S 1 2 ,K,Q Under the accelerated life test, at the kth stress level S k Lower input N k A specimen bearing test while at the kth stress level S k Next, the jth bearing is sequentially tested at the preset test time Corresponding wear performance degradation data measured at where X kji for the stress level S k The measurement value of the performance parameter of the i-th bearing for the j-th bearing, t kji for the stress level S k The time point of the i-th measurement of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com