Real-time combination optimization intelligent boxing simulation method and system

A technology of combined optimization and simulation methods, applied in design optimization/simulation, 3D modeling, virtual/augmented reality, etc., can solve the problems of high packing utilization, affecting packing efficiency, deformation, etc., to improve packing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

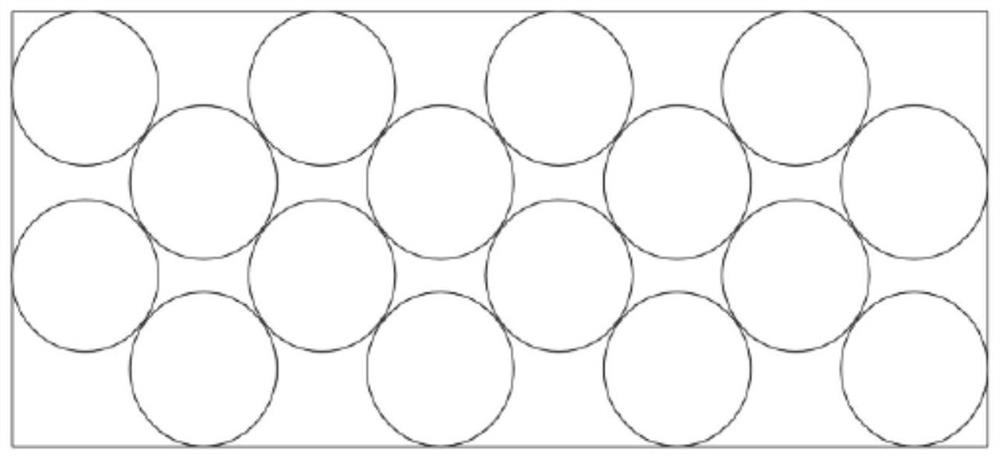

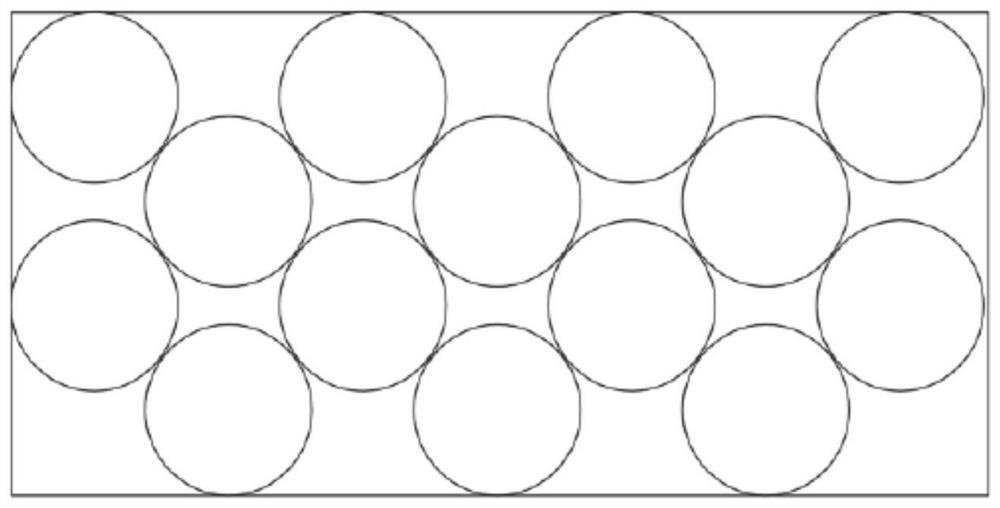

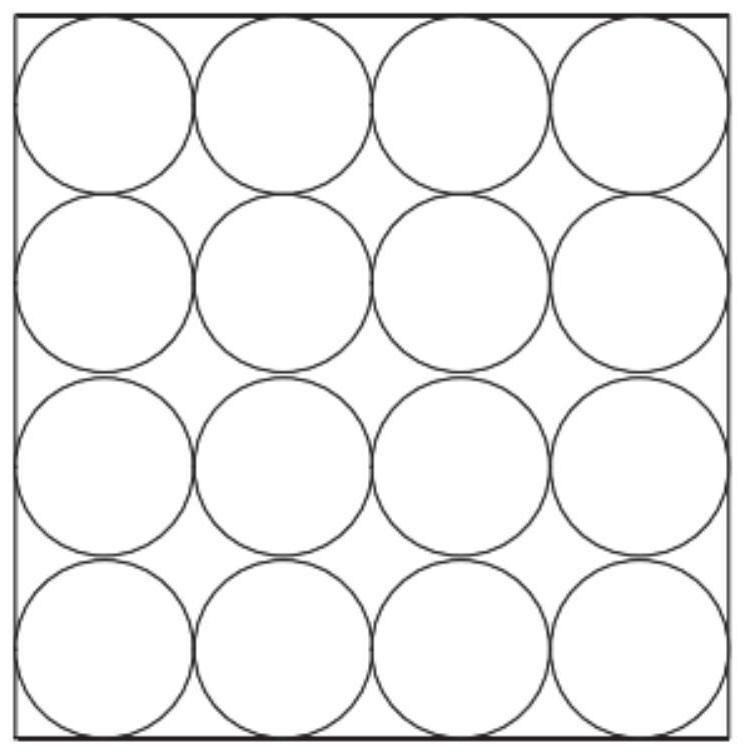

[0032] Such as Figure 5 As shown, this embodiment provides a real-time combined optimization intelligent packing simulation method, which specifically includes the following steps:

[0033] Step 1: Obtain the size of the container and cylindrical cargo, and generate a 3D model of the container and cylindrical cargo.

[0034] In a specific implementation, the size of the container includes the length, width and height of the container; the size of the cylindrical cargo includes the diameter and length of the cylindrical cargo.

[0035] Among them, based on the size of the container and the cylindrical cargo, according to the existing simulation and 3D model generation program or software, the 3D model of the container and the cylindrical cargo can be correspondingly generated.

[0036] Step 2: Select and run a simulation scheme that matches the set simulation requirements, and dynamically display the packing process based on the 3D model of the container and cylindrical cargo...

Embodiment 2

[0069] Such as Image 6 As shown, the present embodiment provides a real-time combined optimization intelligent packing simulation system, which specifically includes the following modules:

[0070] A three-dimensional model generation module, which is used to obtain the size of the container and the cylindrical cargo, and generate a three-dimensional model of the container and the cylindrical cargo;

[0071] Packing process simulation module, which is used to select and run a simulation scheme that matches the set simulation requirements, and dynamically display the packing process based on the three-dimensional model of the container and cylindrical goods;

[0072] Wherein, the set simulation requirements include real-time packaging simulation requirements for a single cylindrical cargo and single-layer cylindrical cargo packaging simulation requirements.

[0073] It should be noted here that each module in this embodiment corresponds to each step in Embodiment 1, and the s...

Embodiment 3

[0075] This embodiment provides a computer-readable storage medium, on which a computer program is stored, and when the program is executed by a processor, the steps in the real-time combined optimization intelligent packing simulation method as described above are implemented.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com