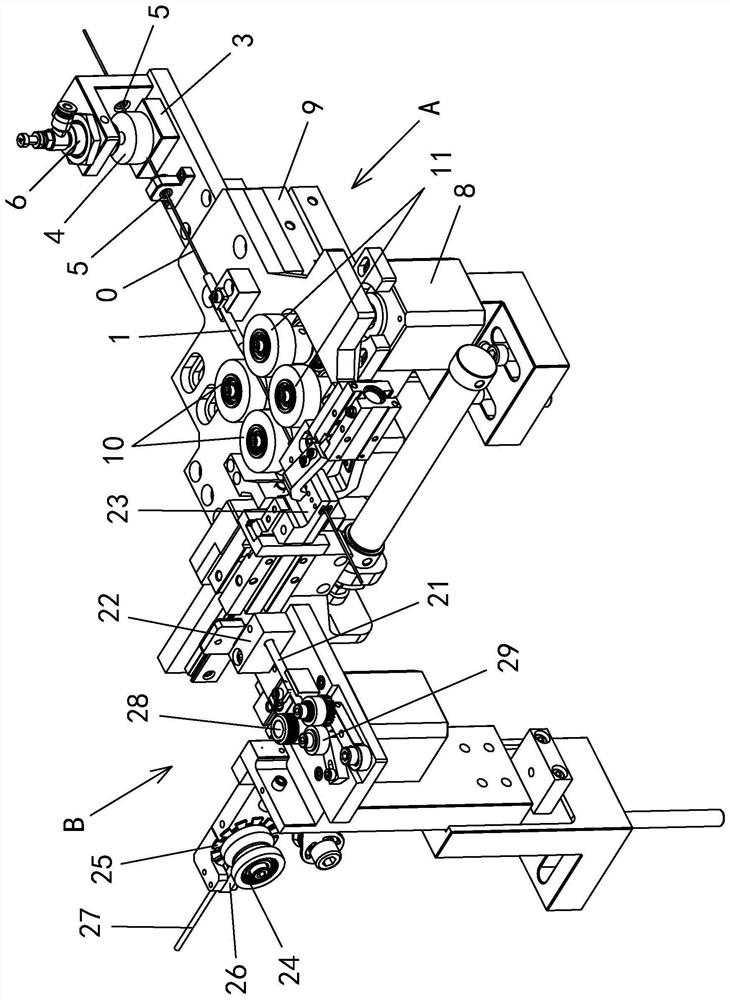

Sleeve threading device

A technology of threading device and bushing, applied in coil manufacturing, electrical components, inductor/transformer/magnet manufacturing, etc., can solve the problems of high labor intensity, low manual operation efficiency, and high labor cost, and achieve labor cost saving, optimal Industrial efficiency and practicality, the effect of avoiding insufficient friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

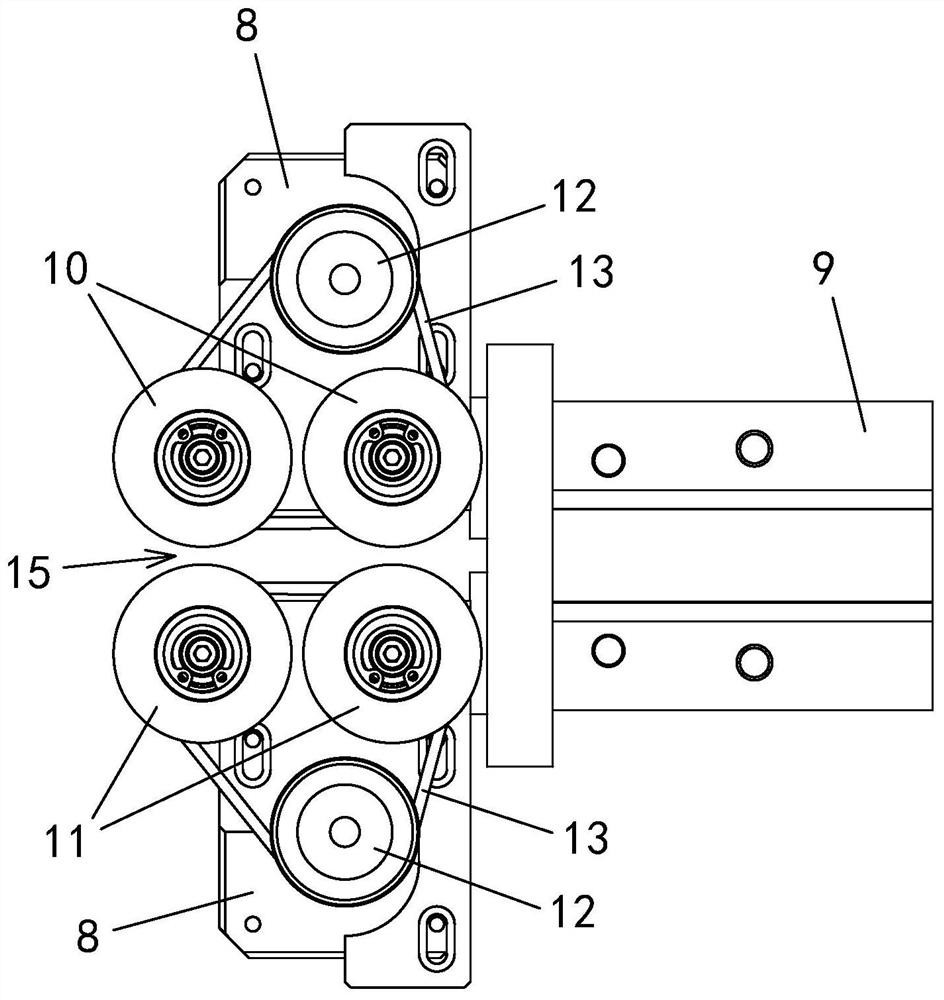

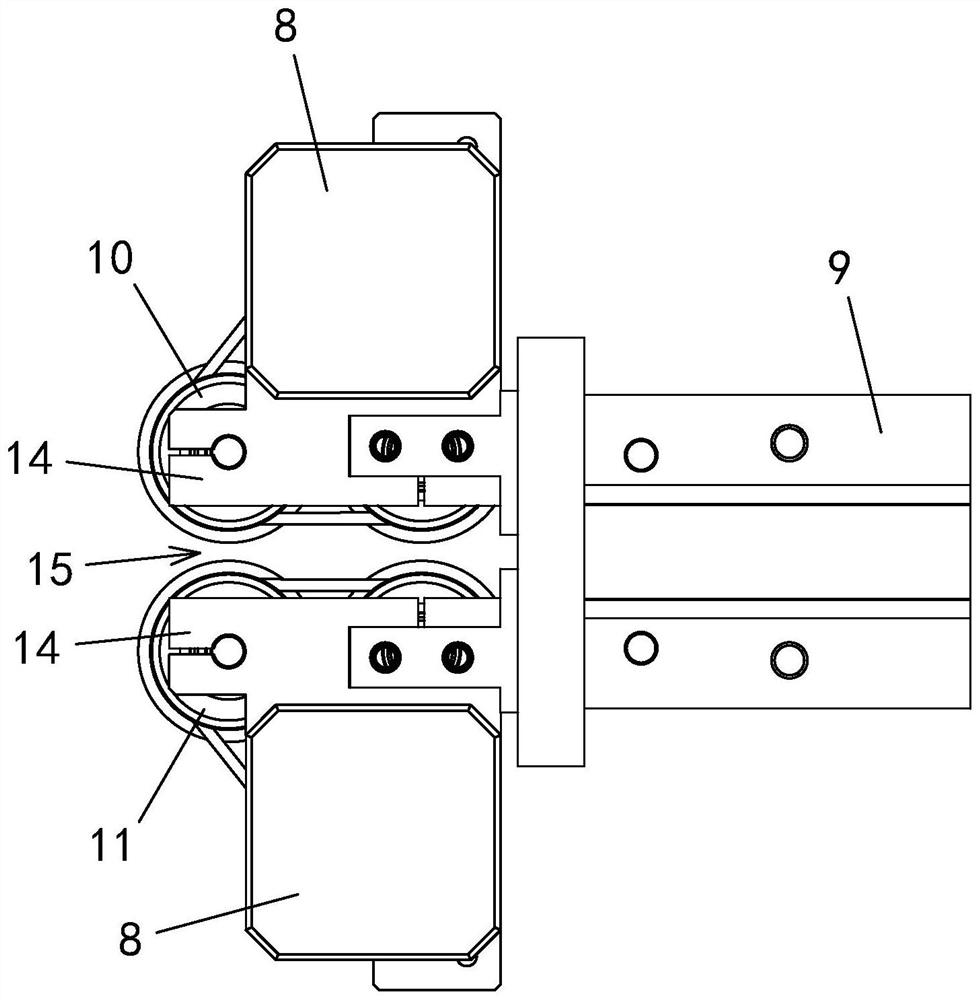

[0050]Embodiment: The following will clearly illustrate this case with drawings and detailed descriptions. After any person skilled in the art understands the embodiment of this case, he can change and modify it by the technology taught in this case without departing from the spirit of this case. with range.

[0051] The terminology used herein is for the purpose of describing particular embodiments only, and is not intended to be limiting of the present case. Singular forms such as "a", "the", "the", "this" and "the", as used herein, also include plural forms.

[0052] The terms “first” and “second” used herein do not refer to a sequence or order, nor are they used to limit the present application, but are only used to distinguish components or operations described with the same technical terms.

[0053] As used herein, "connection" or "positioning" can mean that two or more components or devices are in direct physical contact with each other, or that they are in indirect ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com