Interleaved Boost circuit software control method and system

A software control and circuit technology, applied in control/regulation systems, battery/fuel cell control devices, electrical components, etc., can solve problems such as output voltage oscillation, DCDC module heating, DCDC module damage, etc., to ensure safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

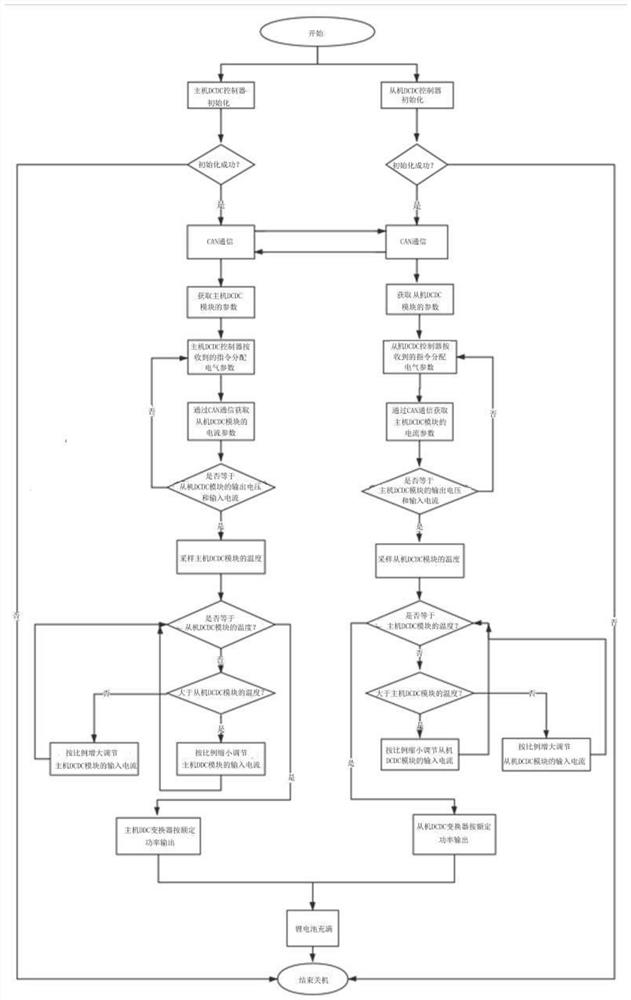

[0045] like figure 1 As shown, the present invention provides a software control method for an interleaved parallel Boost circuit,

[0046] (1) Initialize the parallel output host DCDC controller and multiple slave DCDC controllers, and perform CAN communication between the host DCDC controller and slave DCDC controllers after successful initialization to realize real-time information transmission. The vehicle control module obtains the information of the lithium battery in real time. When the lithium battery needs to be charged, the vehicle control module generates a work order and sends the work order to the hydrogen fuel cell stack and the host DCDC controller. After the hydrogen fuel cell stack receives the work order, it performs a self-inspection. If the self-inspection is successful, it generates a preparation work order and sends the preparation work order to the vehicle control module; after the host DCDC controller receives the work order, it confirms that the host D...

Embodiment 2

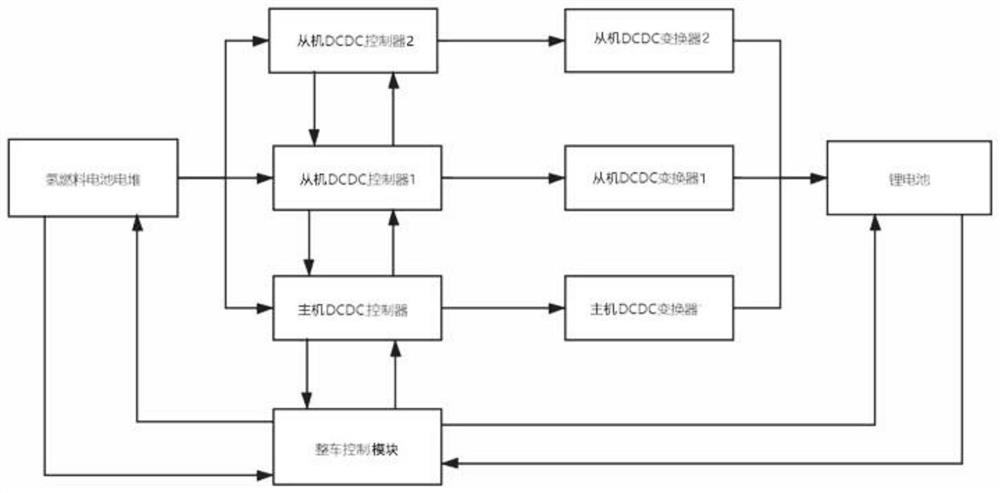

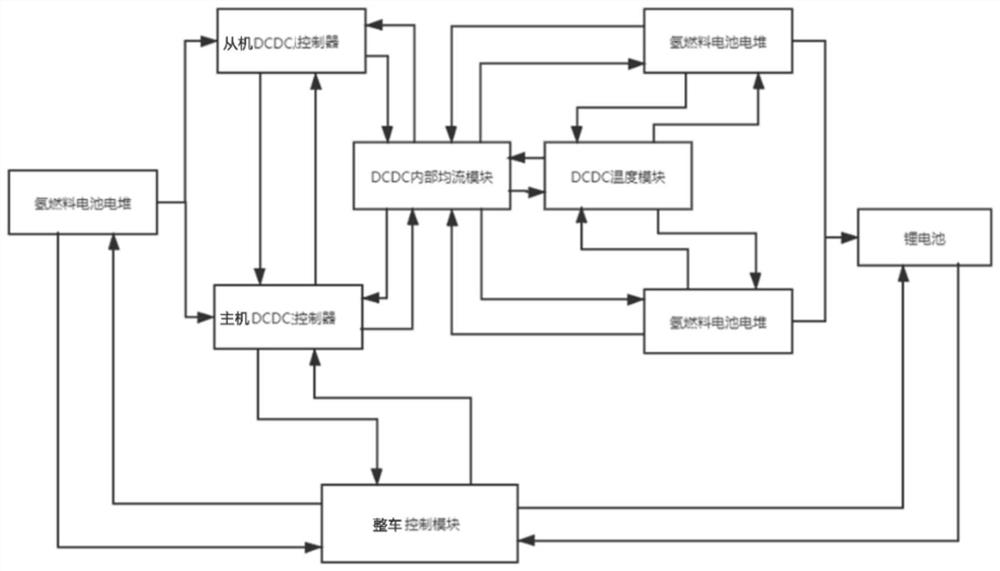

[0057] like figure 2 and 3 As shown, the present invention also provides an interleaved parallel Boost circuit software control system, including a hydrogen fuel cell stack, a vehicle control module, a lithium battery, a master DCDC module and multiple slave DCDC modules. The vehicle control module is electrically connected to the host DCDC module, the hydrogen fuel cell stack and the lithium battery through the Boost circuit, and the host DCDC module and multiple slave DCDC modules are connected in parallel between the hydrogen fuel cell stack and the lithium battery.

[0058] The host DCDC module includes a host DCDC controller, a host DCDC converter, and a host DCDC temperature module, and the slave DCDC module includes a slave DCDC controller, a slave DCDC converter, and a slave DCDC temperature module.

[0059] The host DCDC controller is electrically connected to the vehicle control module; the hydrogen fuel cell stack is electrically connected to the host DCDC control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com