A linear grinding machine for anilox roll body

An anilox roller and grinding machine technology, which is applied in the field of mechanical processing, can solve problems such as difficulty in controlling the grinding amount of the roller body, uncontrollable grinding efficiency, clogging of the grinding roller and the grinding material of the roller body, etc., so as to improve the grinding efficiency and grinding accuracy , to avoid the reduction of grinding efficiency and the reduction of grinding precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

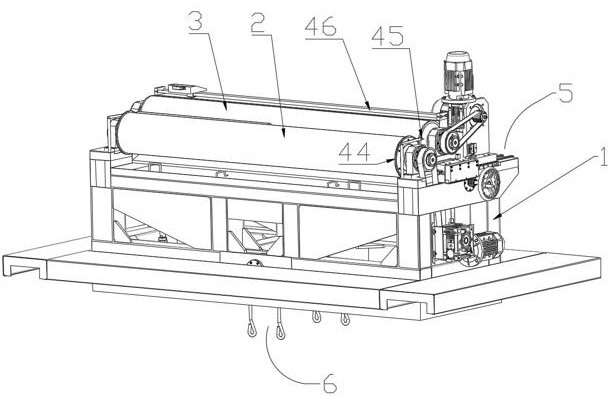

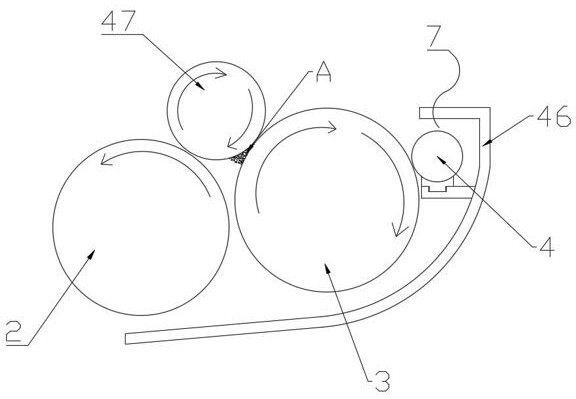

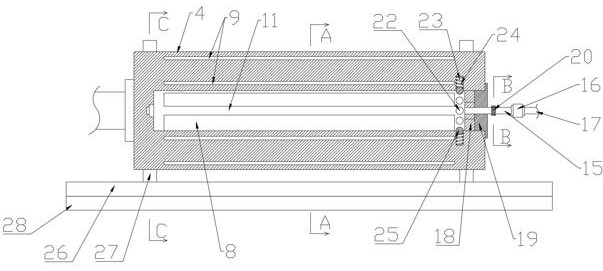

[0036] Embodiment: the present invention provides technical scheme: as Figure 1~2 , a linear grinding machine for an anilox roll body, comprising a frame 1, a load-bearing roll 2, a grinding roll 3, and a rubber-leveling roller 4 are arranged on the upper end of the frame 1, and the load-bearing roll 2, the grinding roll 3, and the rubber-leveling roll 4 are uniformly Connected to the frame 1 through bearing rotation, the load-bearing roller 2 is used to bear the weight of the roller body 47 to be processed, and drives the roller body 47 to rotate, and the surface of the grinding roller 3 is coated with abrasive material, which is used for grinding the roller body 47 and uniform glue Roller 4 is used for auxiliary grinding. Bearing roller 2, grinding roller 3 and cot roller 4 are all driven by motors to rotate. Bearing roller 2 and cot roller 4 are respectively located on both sides of grinding roller 3. Bearing roller 2 is lower than grinding roller 3. , so that the weight o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com