Planetary gear train type grinding machine capable of realizing direction-changing speed adjustment

A planetary gear train and planetary gear technology, which is used in grinding machines, grinding workpiece supports, grinding drive devices, etc., can solve the problems of high spindle speed, insufficient compact mechanism, and difficult to operate, and achieve high transmission power and simple structure. , the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

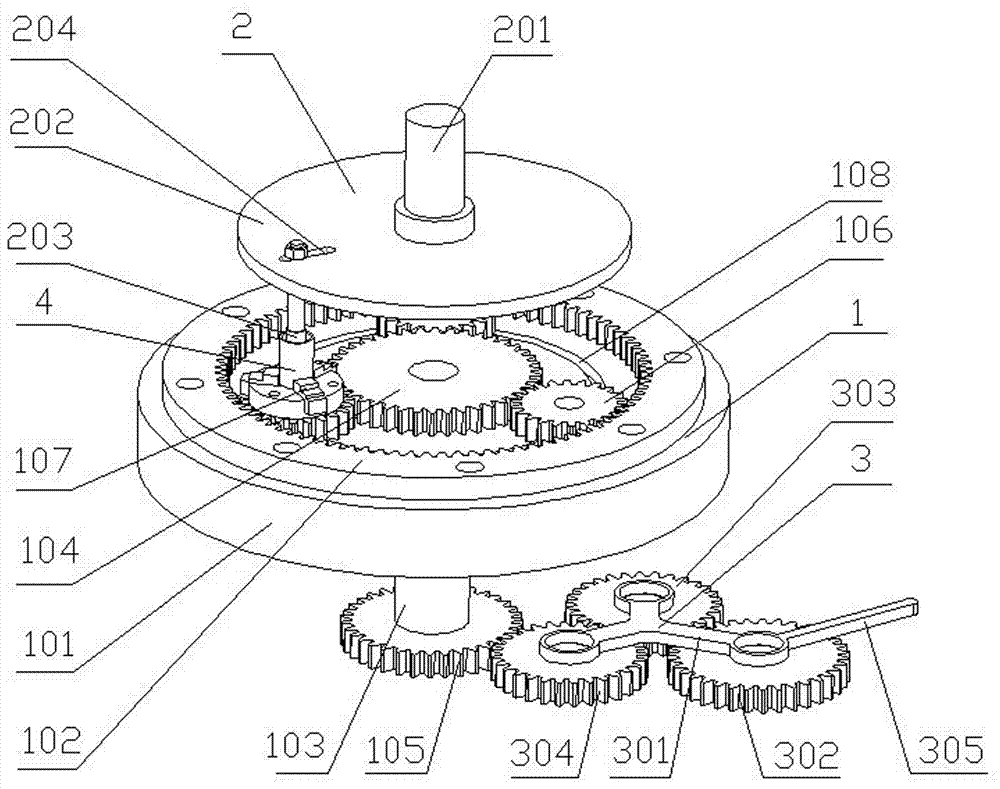

[0018] Such as figure 1 As shown, a planetary gear train grinding machine with variable direction and speed regulation of the present invention includes a frame and a planetary gear train mechanism 1 , a grinding mechanism 2 and a direction changing drive mechanism 3 arranged on the frame.

[0019] The planetary gear mechanism 1 includes a workbench 101 fixed on a frame. A ring gear 102 and a sun gear shaft 103 are provided on the workbench 101 . The inner ring gear 102 is fixedly connected with the workbench 101, and the center of the inner ring gear 102 is provided with a shaft hole on the workbench 101, and the sun gear shaft 103 is rotatably installed in the shaft hole through a bearing, and its two ends are respectively exposed to the working table. Both sides of Taiwan 101. A first sun gear 104 is fixed on an end of the sun gear shaft 103 close to the ring gear 102 , and a second sun gear 105 is fixed on an end of the sun gear shaft 103 away from the ring gear 102 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com