Synthesis method of weather-resistant epoxy resin curing agent

A synthesis method and technology of cyclohexane, applied in chemical instruments and methods, preparation of amino compounds, preparation of organic compounds, etc., can solve problems such as coating failure, acid rain erosion, poor acid resistance of zinc-aluminum coatings, etc., to achieve High yield, green and simple process

Inactive Publication Date: 2021-10-12

上海库曜新材料有限公司

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the acid resistance of the zinc-aluminum coating is not good. If it is used outdoors alone, it will be corroded by acid rain and cause the coating to fail.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-9

[0048] Examples 1-9 relate to a new synthesis method of a weather-resistant epoxy resin curing agent, its composition and mass dosage are shown in Table 1 below; the yield is shown in Table 3.

[0049] Table 1

[0050]

[0051]

Embodiment 1

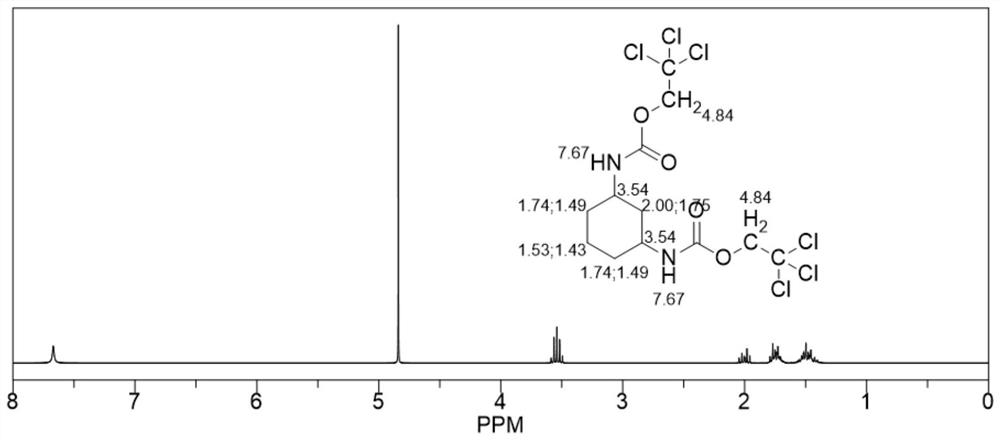

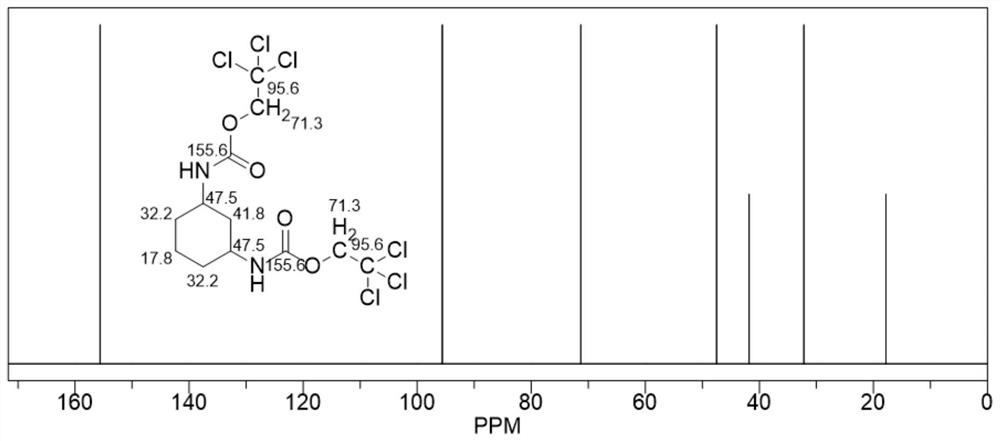

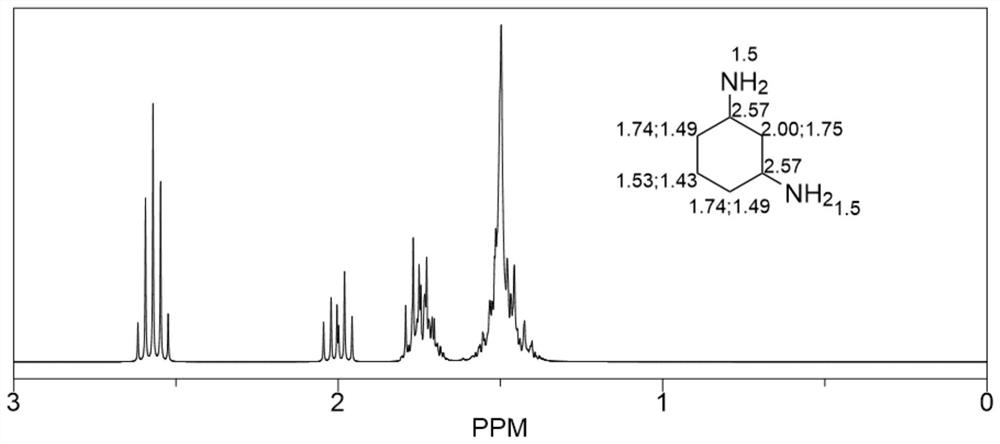

[0052] The intermediate b nuclear magnetic spectrum that embodiment 1 makes is as figure 1 , 2 Shown; product NMR spectrum as image 3 , 4 shown.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a synthesis method of a weather-resistant epoxy resin curing agent. The method comprises the following steps of: enabling cyclohexanedicarboxylic acid and azidoformic acid 2, 2, 2-trichloroethyl ester to react under the catalysis of DMAP and copper acetate to generate an intermediate b, and enabling the intermediate b to react with potassium carbonate to generate 1, 3-bis (aminomethyl) cyclohexane. According to a traditional synthesis method of 1, 3-bis (aminomethyl) cyclohexane, m-xylylenediamine (MXDA) is subjected to benzene ring hydrogenation reduction to prepare the 1, 3-bis (aminomethyl) cyclohexane. The invention provides the novel synthesis method of 1, 3-bis (aminomethyl) cyclohexane (1, 3-BAC), and the method is simple in process.

Description

technical field [0001] The present invention relates to the synthesis field of curing agent for epoxy resin, relates to a synthesis method of weather-resistant epoxy resin curing agent, in particular to a kind of 1,3-bis(aminomethyl)cyclohexane (1,3-BAC ) synthesis method. Background technique [0002] At present, the zinc-aluminum coating on the market is used as outdoor building steel, and has incomparable anti-corrosion performance of the coatings currently on the market. However, the acid resistance of the zinc-aluminum coating is not good. If it is used alone outdoors, it will be corroded by acid rain and cause the coating to fail. [0003] 1,3-bis(aminomethyl)cyclohexane (1,3-BAC) is commonly used as a curing agent for epoxy resins. It has the advantages of room temperature curing, heat resistance, water resistance, chemical resistance and weather resistance. Because of its low viscosity and good appearance after reacting with epoxy resin to form a film, it is also ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C07C209/62C07C211/36C07C269/00C07C271/24C08G59/50

CPCC07C209/62C07C269/00C08G59/5026C07C2601/14C07C271/24C07C211/36

Inventor 姚下银

Owner 上海库曜新材料有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com