Simulation method for contact dynamic characteristics of high-speed and heavy-duty ball bearings in liquid rocket engines

A liquid rocket, dynamic characteristics technology, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve problems such as increased vibration, difficult solution convergence, and reduced rotor system accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

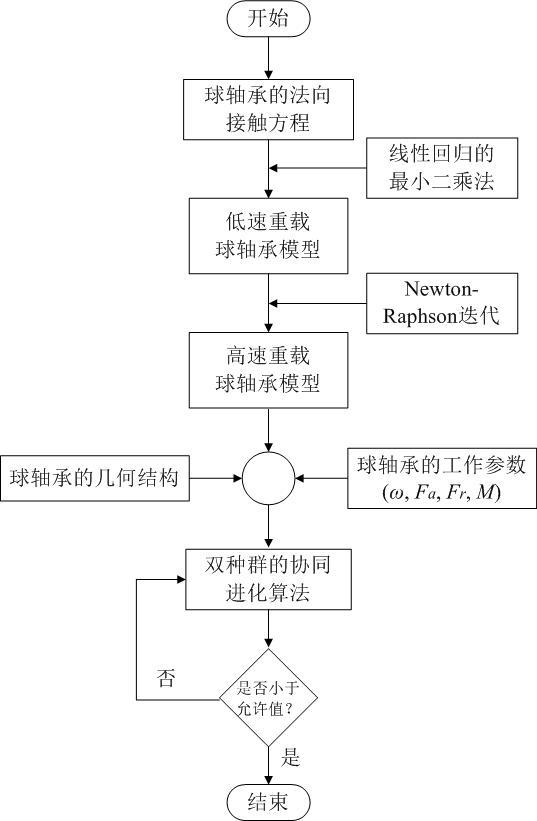

[0075] like figure 1 As shown, this embodiment provides a method for simulating the contact dynamic characteristics of a high-speed, heavy-duty ball bearing of a liquid rocket engine. The simulation process is executed on matlab, and specifically includes the following steps:

[0076] Step 1: Establish the equation of the normal contact problem based on the Hertz theory of semi-infinite length space, and then combine the least square method of linear regression to perform simplified calculations to obtain the contact normal stress of the ball bearing;

[0077] Among them, the simplified normal contact problem equation is as follows:

[0078] (1)

[0079] In the formula:

[0080] (2)

[0081] (3)

[0082] (4)

[0083] (10)

[0084] (11)

[0085] in: a is the semi-major axis of the contact ellipse, b is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com