Acrylic copolymer coagulant and method for preparing graft copolymer using same

A technology of acrylic copolymer and coagulant, applied in the field of acrylic copolymer coagulant, can solve the problems of deterioration of impact strength and surface gloss characteristics of ABS graft copolymer, decrease in productivity, etc., to improve latex stability, processability and appearance Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] 2. Preparation of Acrylic Copolymer Coagulant

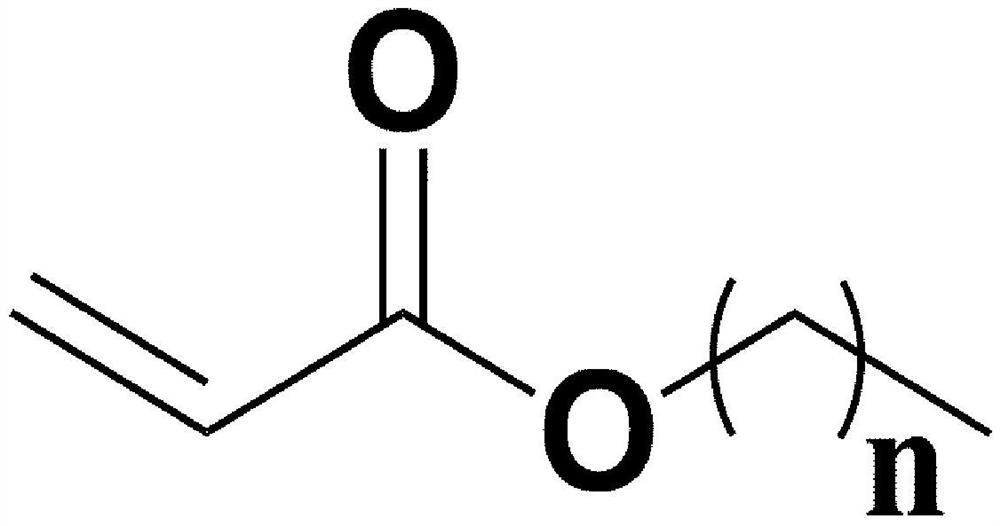

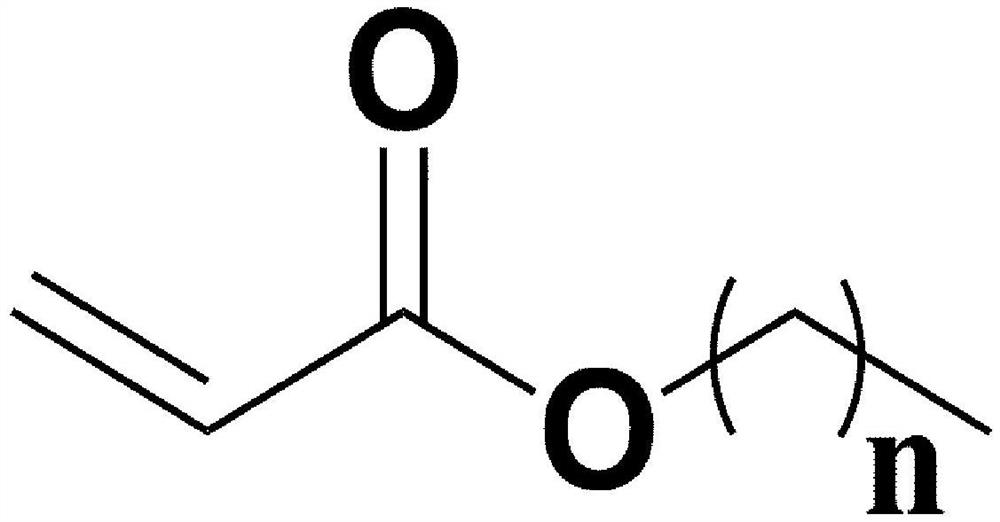

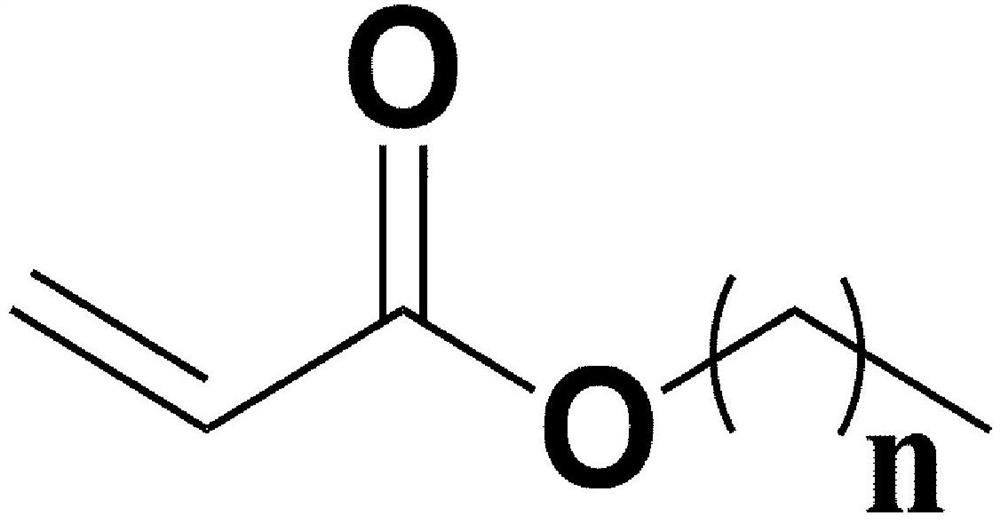

[0068] The acrylic copolymer coagulant according to one embodiment of the present invention can be produced by a method comprising: providing a polymerization solution containing a monomer mixture containing a carboxylic acid monomer and an acrylic monomer represented by Chemical Formula 1, and a first emulsifier; and adding the first emulsifier into a reactor, and then performing polymerization while continuously feeding the polymerization solution.

[0069] The content of the carboxylic acid monomer unit in the monomer mixture may be the same as the content of the carboxylic acid monomer unit in the acrylic copolymer coagulant.

[0070] Meanwhile, the total amount of the first emulsifier and the second emulsifier may be 0.2 to 0.6 parts by weight or 0.3 to 0.5 parts by weight relative to 100 parts by weight of the monomer mixture. When the above range is satisfied, the average particle diameter of the acrylic copolymer ...

experiment example 1

[0105] The properties of the acrylic copolymer coagulants of Examples and Comparative Examples were evaluated by the methods described below, and the results are shown in the table.

[0106] (1) Average particle diameter (nm): Measured by a dynamic light scattering method using a Nicomp 380HPL instrument (manufactured by Nicomp).

[0107] (2) Weight-average molecular weight (g / mol): acrylic acid copolymer coagulant latex was dissolved in tetrahydrofuran (THF) with a concentration of 2 mg / ml, stirred for 12 hours, and filtered through a 45nm polytetrafluoroethylene filter, Measured by gel permeation chromatography (GPC) analysis.

[0108] (3) Polymerization conversion rate (%): By drying 1 g of acrylic copolymer coagulant latex in an oven set at 135° C. for 20 minutes, measure the solid content, and then divide the measured solid content by the theoretical solid content (target TSC) to determine.

experiment example 2

[0110] The physical properties of the second butadiene rubber polymer latexes of Examples and Comparative Examples were measured by the methods described below, and the results are shown in the table.

[0111] (4) Aggregation phenomenon: When the measured amount (ppm) of aggregates is 30,000 ppm or more, or when phase separation is visually observed during stirring of the second butadiene rubber polymer latex, it is determined that aggregation occurs .

[0112] (5) Average particle diameter (nm): Measured by a dynamic light scattering method using a Nicomp 380HPL instrument (manufactured by Nicomp).

[0113] (6) Particle size distribution: Measured by a dynamic light scattering method using a Nicomp 380HPL instrument (manufactured by Nicomp).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com