Non-woven fabric filter material with wave type wrinkle structure

A filter material, non-woven technology, applied in the direction of dispersed particle filtration, dispersed particle separation, layered products, etc., can solve the problems of short replacement cycle, low usage rate, large resistance, etc., to improve filtration efficiency and save maintenance costs , the effect of prolonging the replacement cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

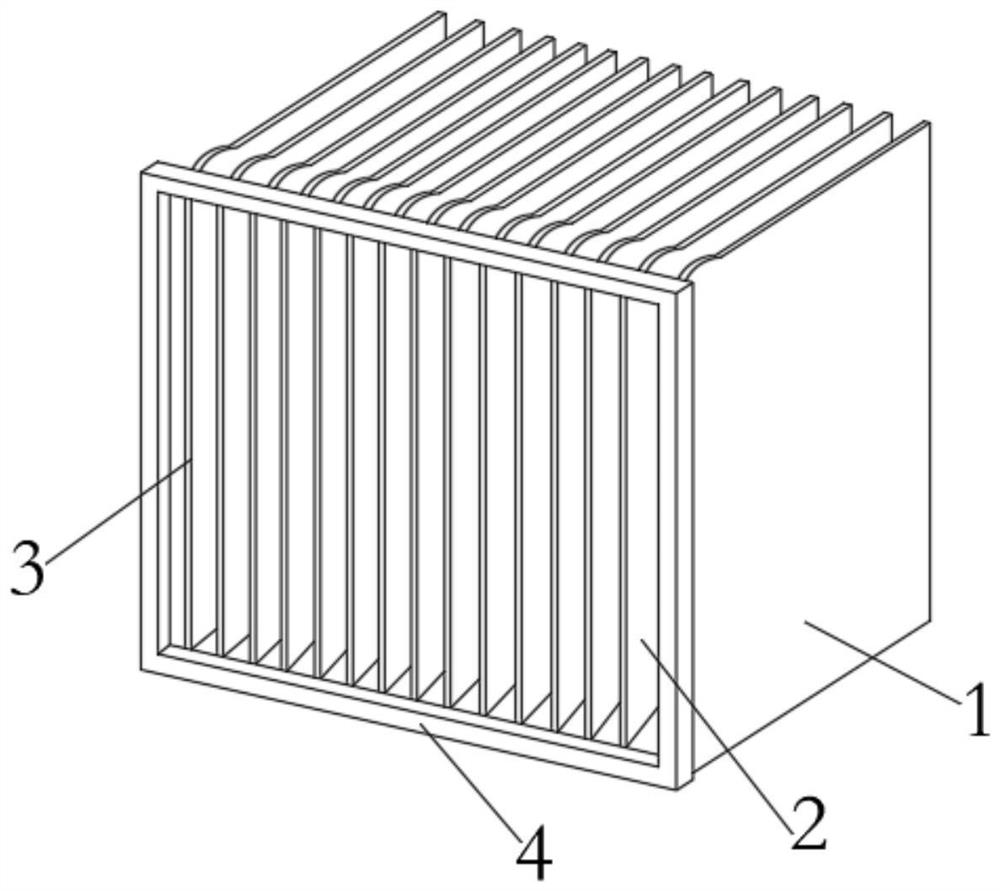

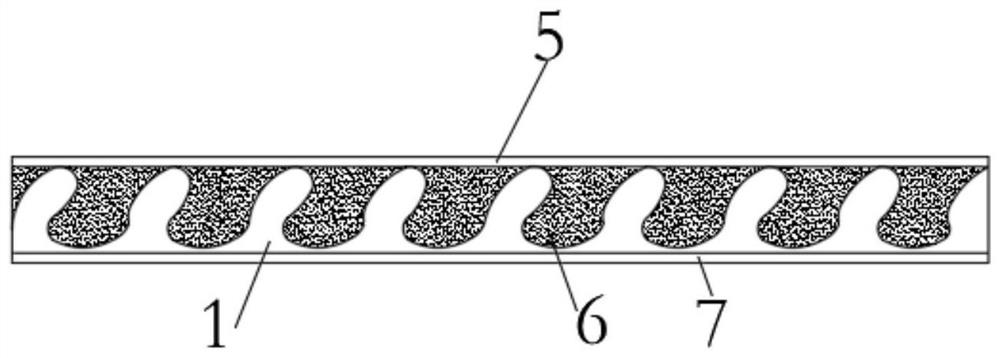

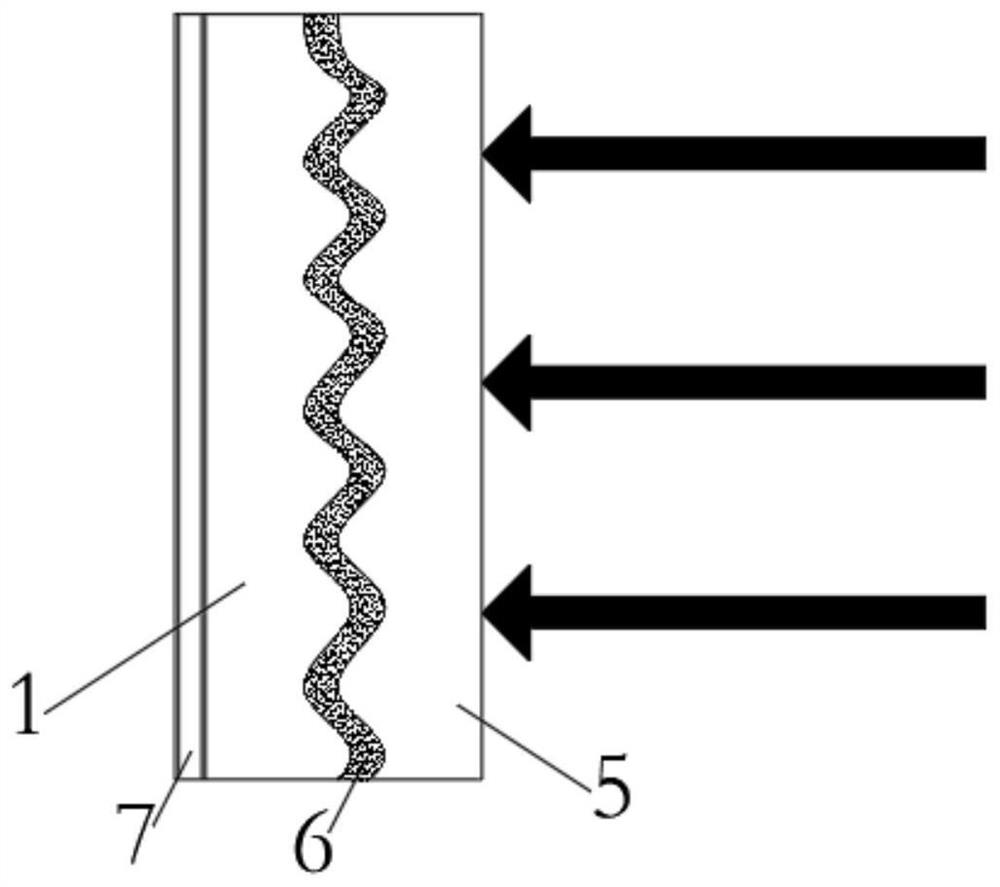

[0018] The present invention provides a technical solution: a non-woven fabric filter material with a wavy pleat structure, including a filter cloth 1 and a frame 4, the filter cloth 1 is provided with a filter port 3, and the filter cloth 1 is provided with a Filter cartridge 2, the frame 4 is fitted on the filter port 3, the inside of the filter cloth 1 is provided with a first filter layer 5, a pleated layer 6 and a second filter layer 7, and the pleated layer 6 is located on the first filter layer 5 and the second filter layer 7, the folded layer 6 is distributed in a wave shape, triple filtering, which can effectively filter the dust particles in the gas, and the filter is more thorough. resistance, but also achieve the effect of deep filtration.

[0019] As a further preferred mode of the present invention, the filter cartridges 2 are evenly distributed in the filter cloth 1, the filter cartridges 2 are independent cylinders, and the filter cartridges 2 are separated by ...

Embodiment 2

[0025] Glass fiber cotton is made of glass balls or waste glass through high-temperature melting, wire drawing, winding, weaving and other processes. When glass fiber cotton is used as a filter material, it is generally made into a plate shape and installed in the filter. When the air is filtered, the air first touches the surface of the glass fiber cotton material, because the glass fiber cotton has a filamentary structure inside, and the filaments between the filaments The arrangement is relatively tight, which can directly filter the dust particles in the air. For some small dust particles, they will be embedded in the gap between the inner filaments of the glass fiber cotton. The internal structure of the glass fiber cotton is relatively fixed, and the dust holding capacity is limited. , when the dust particles on the glass fiber cotton gather more, it is necessary to replace the glass fiber cotton as a whole.

[0026] The above-mentioned examples 1-2 respectively adopt tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com