Towel compressing equipment

A technology of equipment and towels, applied in the direction of presses, textiles and papermaking, manufacturing tools, etc., can solve the problems of unfavorable continuous production, low production efficiency, high comprehensive cost, improve product competitiveness, reduce labor costs, and reduce manual operations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

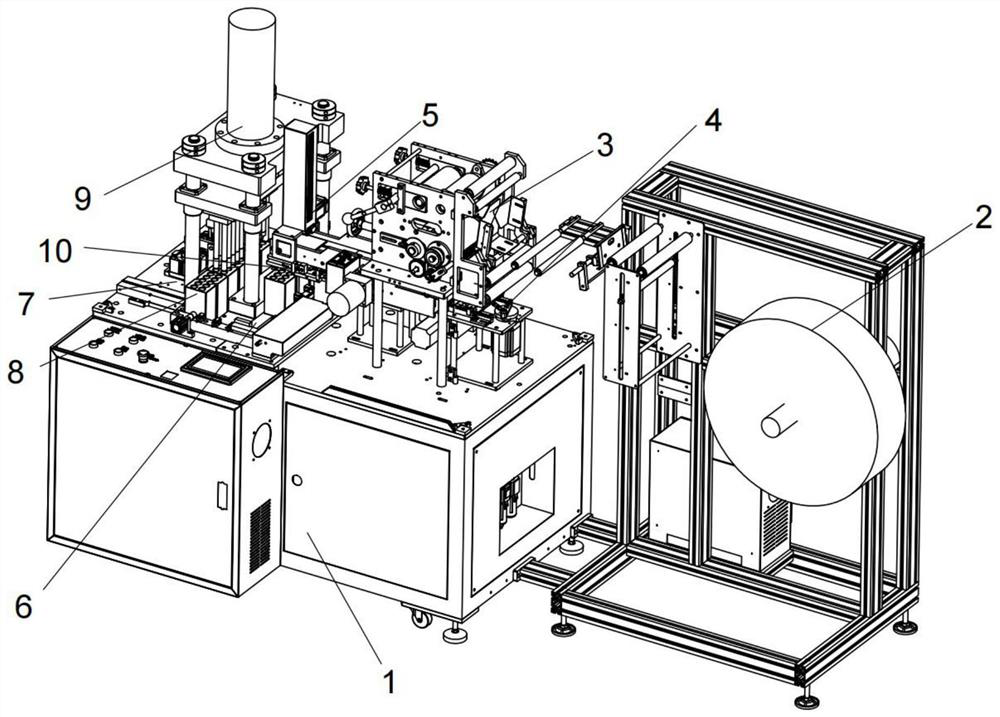

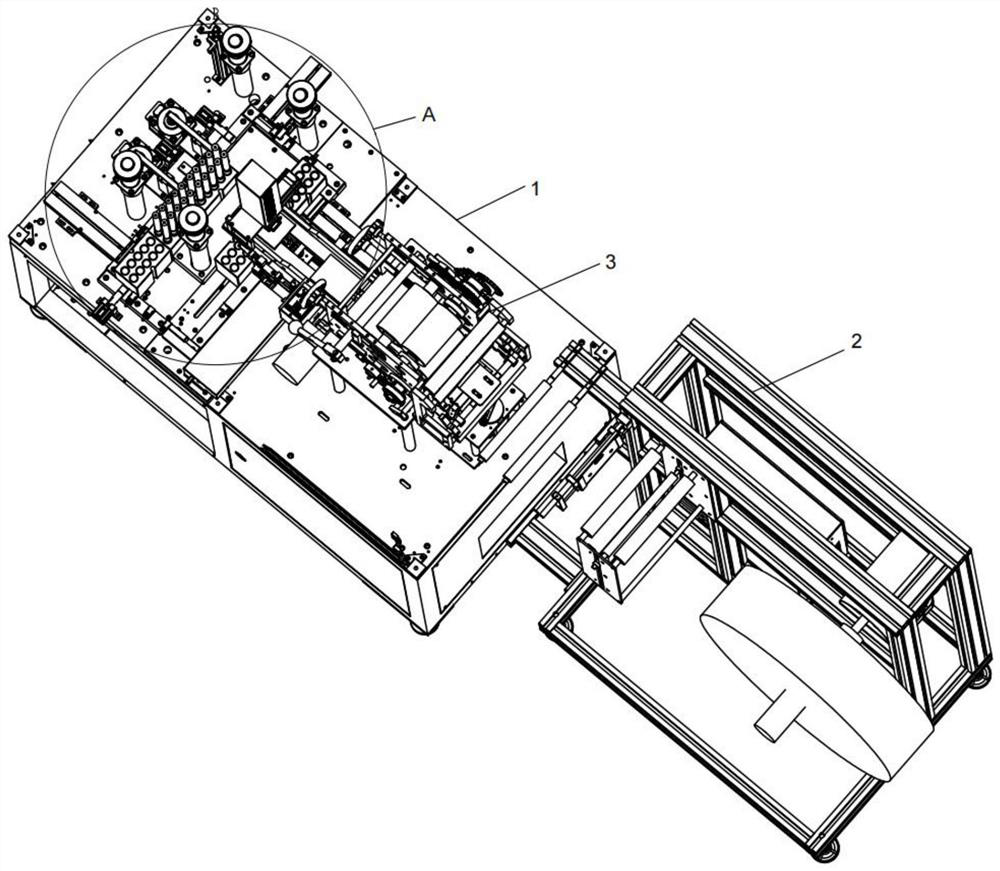

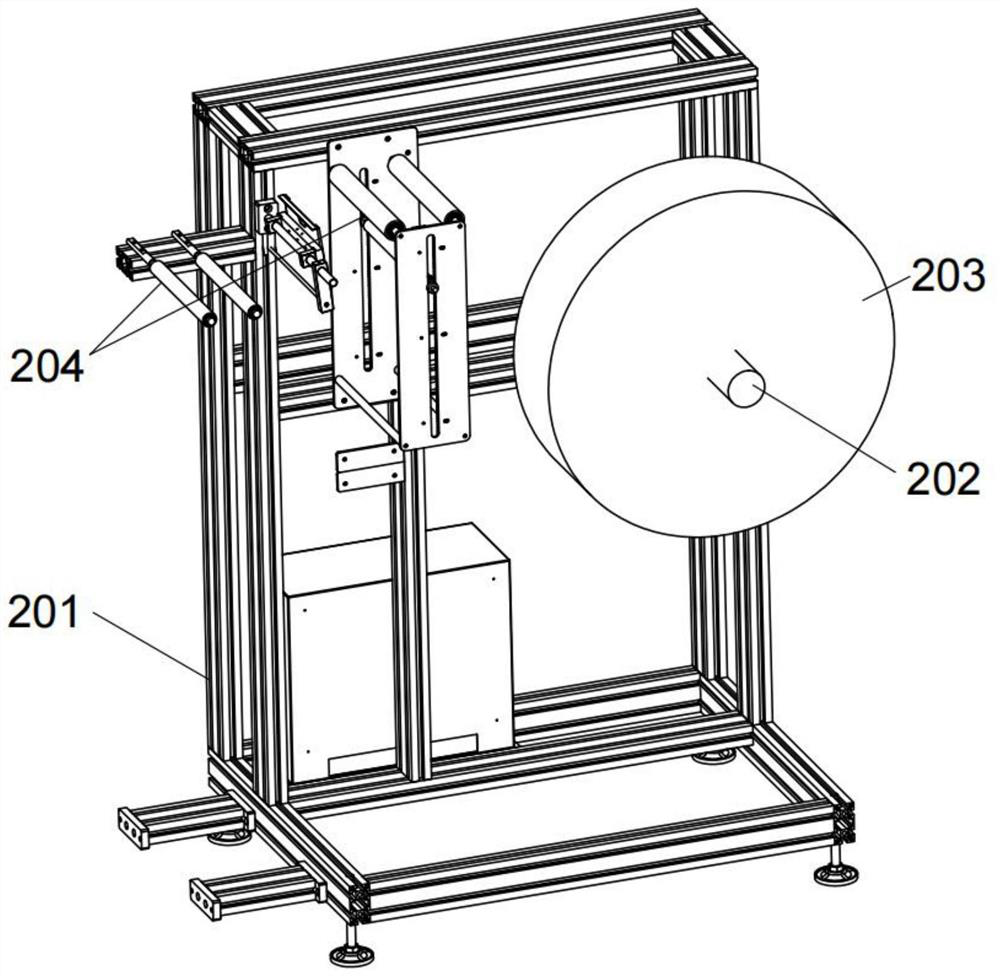

[0036] see Figure 1-Figure 9 , a kind of compressed towel equipment, comprising a general control cabinet 1, a cloth conveying mechanism 2 is fixedly installed on the right side of the general control cabinet 1, a rolling cutting mechanism 3 is fixedly installed on the left side of the cloth conveying mechanism 2, the rolling The bottom of the cutting mechanism 3 is fixedly equipped with a cloth folding conveying mechanism 4, and the left side of the cloth folding conveying mechanism 4 is movably installed with a cloth punching mechanism 5, and the bottom of the cloth punching mechanism 5 is provided with a toggle mechanism 6 A mold return mechanism 7 is fixedly installed on the left side of the toggle mechanism 6, and a plurality of compression molds 8 are movable on the top of the mold return mechanism 7, and a compression mechanism 9 is fixedly installed on the left side of the top of the mold return mechanism 7. .

[0037] see Figure 1-Figure 3 , the cloth conveying me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com