Pipe fitting feeding mechanism, tubular product machining assembly and tubular product machining machine

A technology of feeding mechanism and pipe fittings, which is applied in the direction of conveyors, conveyor objects, fixed drilling machines, etc., and can solve problems such as the stability of feeding needs to be improved, manual removal, and material blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

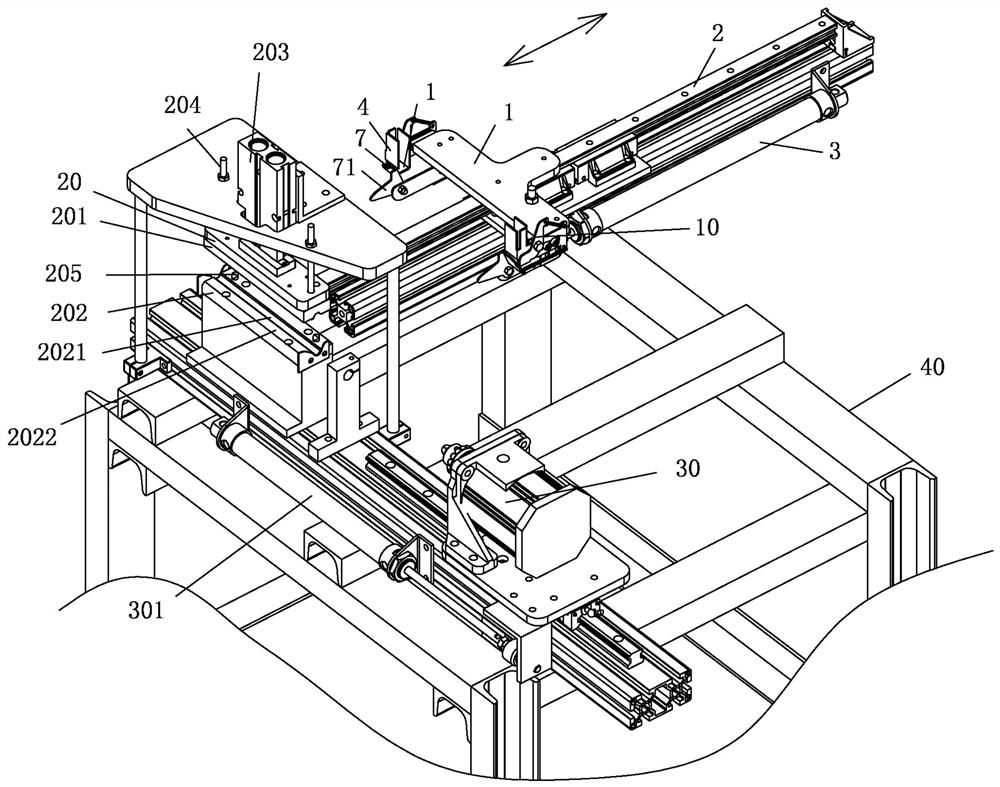

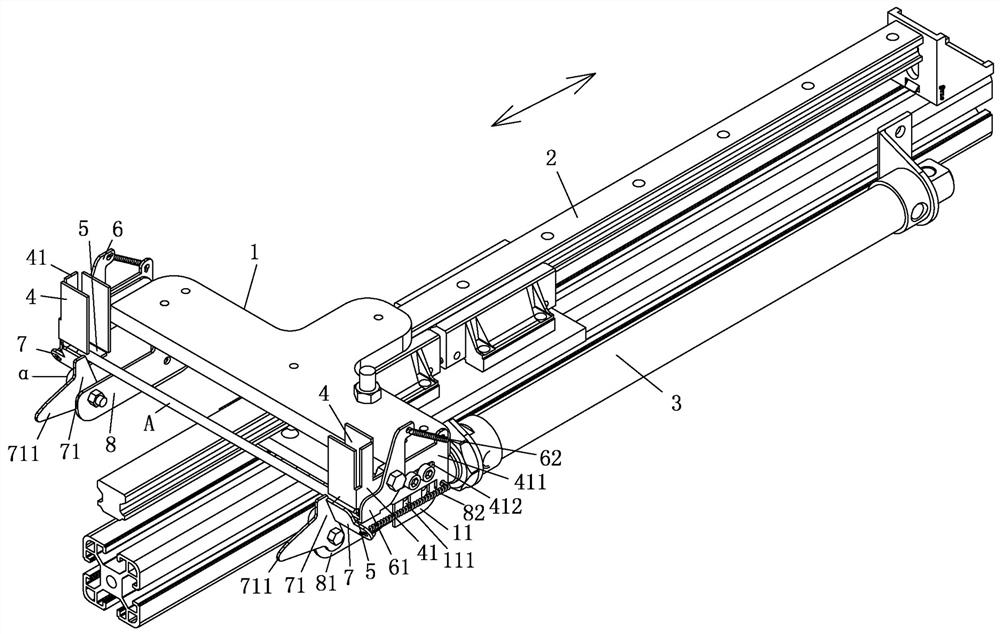

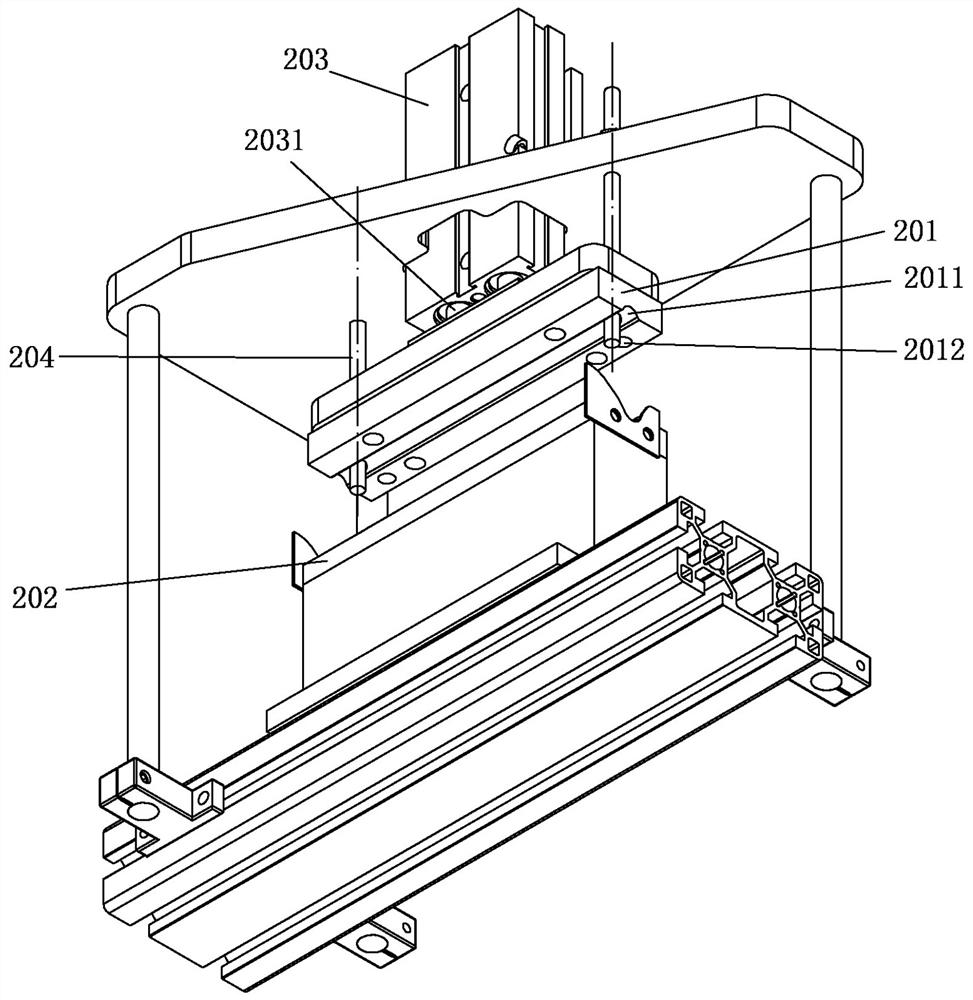

[0036] Such as Figure 1 to Figure 3 As shown, a tubular product processing assembly includes a tubular feeding mechanism 10, a fixing fixture 20 and a shaping tool. The pipe feeding mechanism 10 includes a fixed base 1 that can move horizontally and linearly reciprocatingly on the frame 40. A guide rail 2 is installed, and the bottom of the fixed seat 1 is slidably connected with the guide rail 2, and the pushing cylinder 3 driving the reciprocating motion of the fixed seat 1 is installed on the frame 40; A fixed seat side plate 11 is respectively installed on both sides parallel to the advance direction of the seat, and a guide groove 4 is respectively installed on the side where each said fixed seat side plate 11 is located, and the described guide groove 4 is a through groove and the two guide grooves 4 The notches are opposite, and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap