Shield tunnel longitudinal joint structure in high-intensity earthquake active fault area

A technology of active faults and shield tunnels, which is applied in tunnels, tunnel linings, underground chambers, etc., can solve problems such as large shear and tension forces at longitudinal joints, complex stratum forces, and damage to longitudinal joints of shield tunnels, achieving improved The ability to resist seismic loads, increase flexibility, and easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

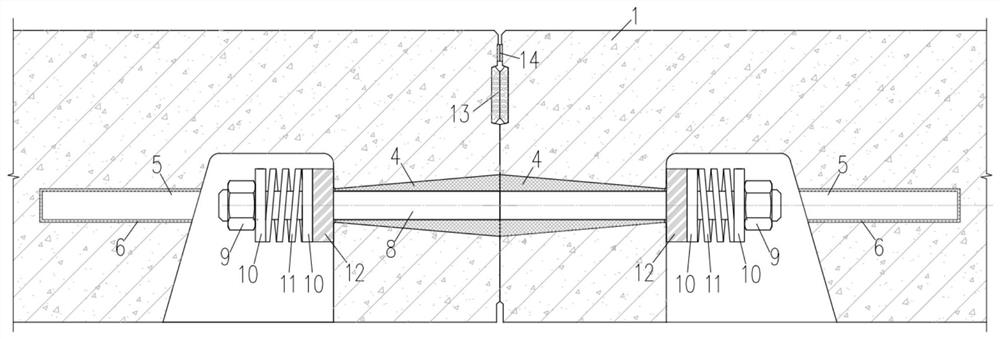

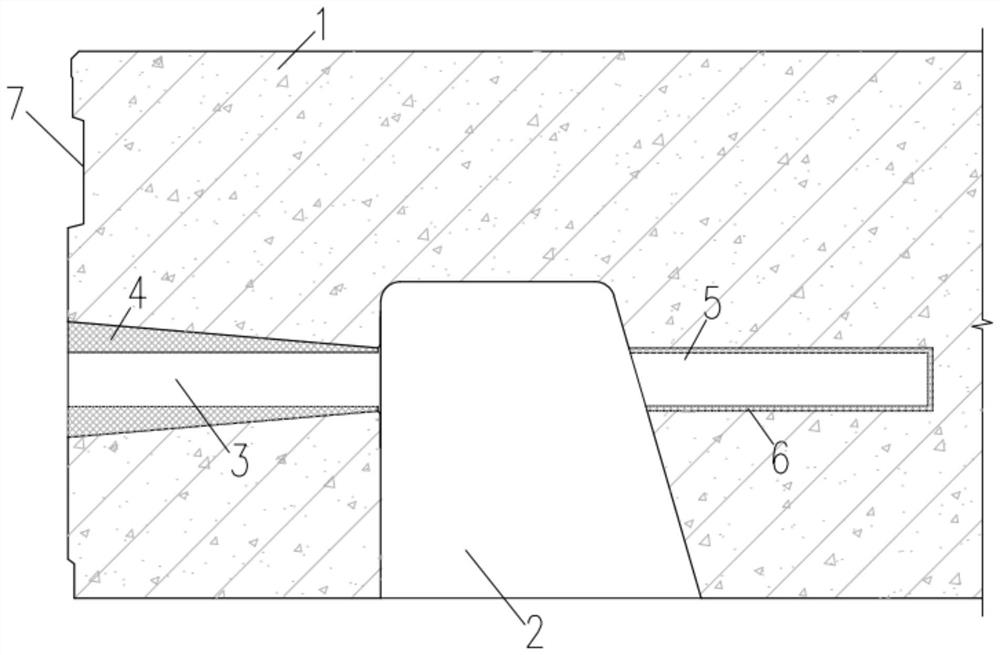

[0041] like Figure 1 to 6 , The longitudinal joint structure highly seismic active fault region tunnel, the screw 8 comprises a plurality of reinforced concrete segment 1 and disposed in parallel; each screw 8 are disposed on two adjacent reinforced concrete segment 1 between two adjacent reinforced concrete segments 1 are connected to.

[0042] Wherein each of the reinforced concrete segment 1 is provided with a tapered hole position of the screw bolt 8 from the outside are successively comprising communication 3, the bolt hole 2 and the bolt mounting the hand guide hole 5;

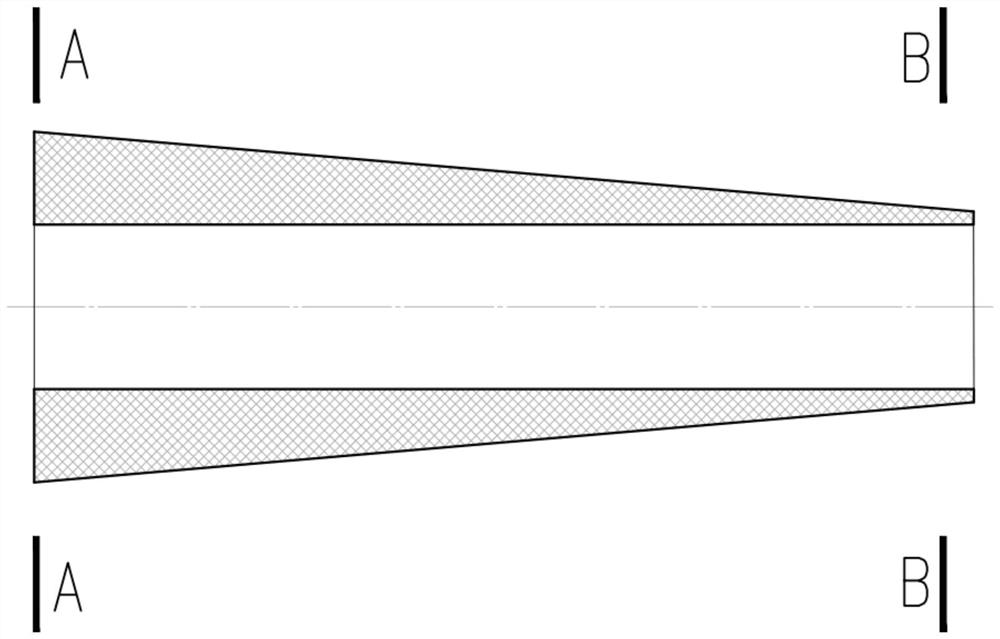

[0043] Each end of the tapered bolt holes 3 are larger than the pore diameter of the tapered bore of the other end of the aperture, the larger end of the aperture positioned adjacent to two reinforced concrete segment 1 of the connection surface, the smaller the aperture the bolt end of hand hole 2 connect;

[0044] Large aperture at one end of each of the tapered aperture of the bolt holes 3 are smaller por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com