Magnetic stirring high-temperature and high-pressure oil gas fluid sample preparation device and sample preparation method

A magnetic stirring, high temperature and high pressure technology, applied in the direction of sampling, instruments, scientific instruments, etc., can solve the problems of potential safety hazards, affecting operation, large space occupation, etc., achieve novel structural design, reduce power consumption, and occupy an area small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

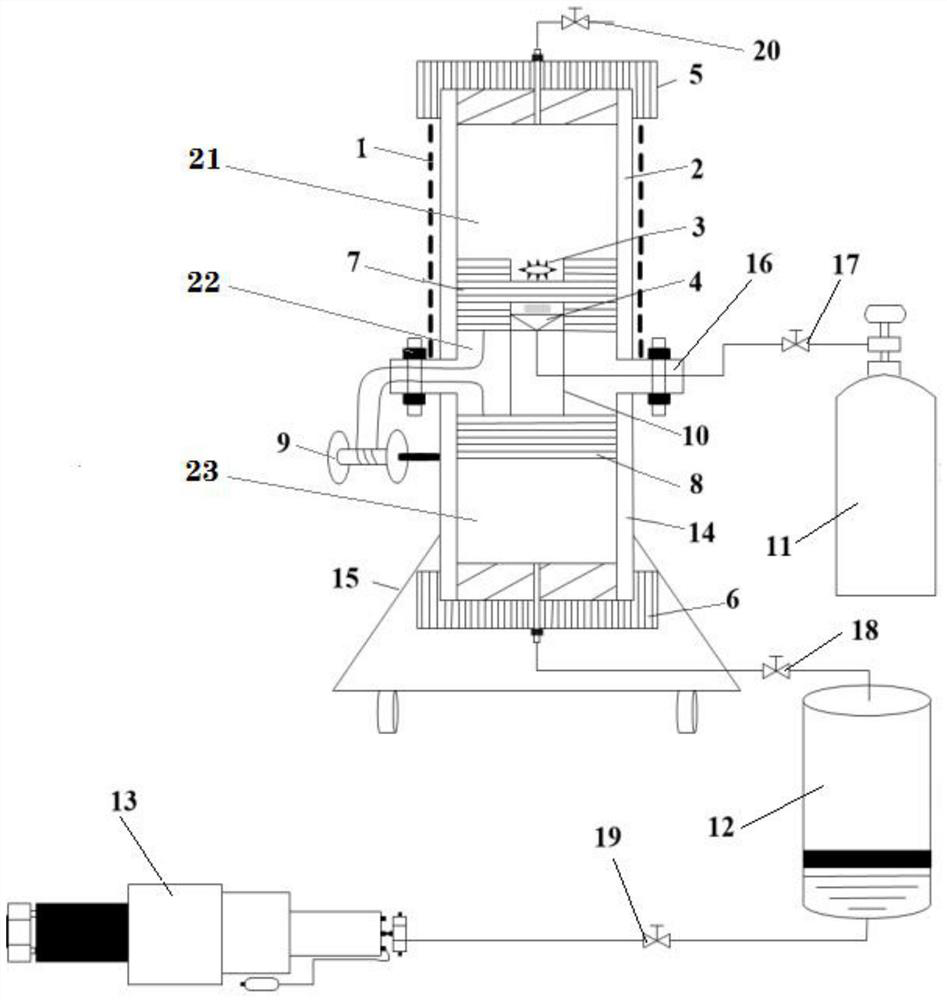

[0028] like figure 1 As shown, a magnetically stirred high-temperature and high-pressure oil-gas fluid sampler includes a heating jacket 1, a high-pressure chamber with magnetic stirring, an external gas cylinder 11, an intermediate container 12, and a high-pressure gas pump 13. The interior of the high-pressure chamber is provided with three The chambers are, from top to bottom, the first chamber 21, the second chamber 22 and the third chamber 23. The first chamber 21 is provided with pipelines for sample input and sample preparation and transfer out. The third chamber 23 communicates with the top of the intermediate container 12 through a pipeline, and the bottom of the intermediate container 12 communicates with the high-pressure gas pump 13 through a pipeline; the heating jacket 1 is wrapped in the first chamber 21 The outer periphery of the first chamber 21 is provided with a magnetic stirrer 3, and an air motor 4 is arranged below the magnetic stirrer 3, and the air moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com