Square wave circulating liquid cooling device for strip-shaped flexible circuit board

A flexible circuit board, flexible circuit technology, applied in the direction of cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc. problem, to achieve a good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

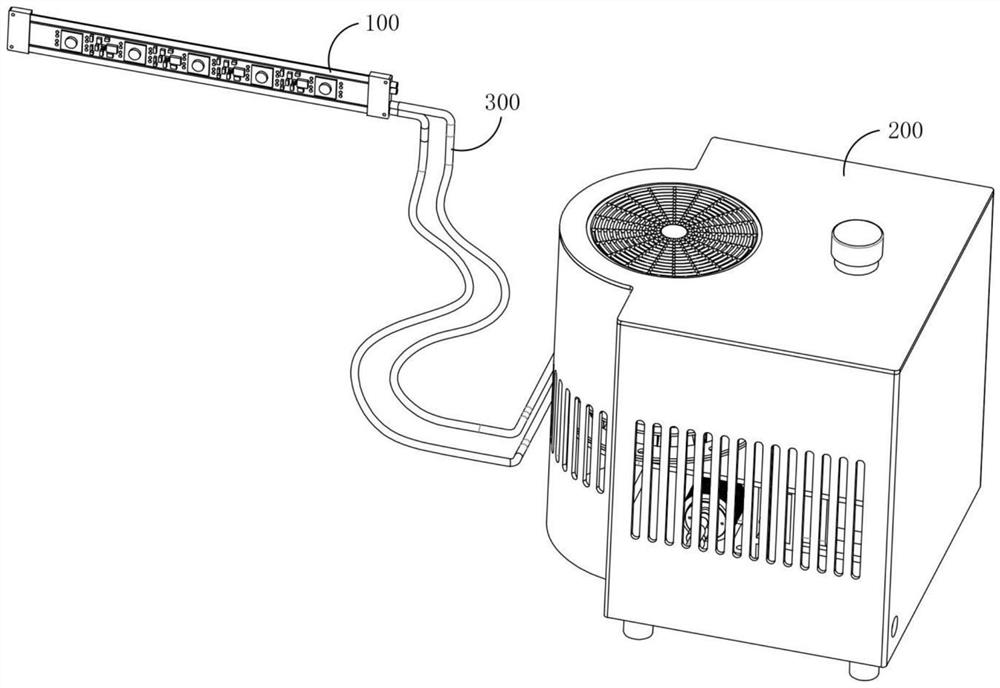

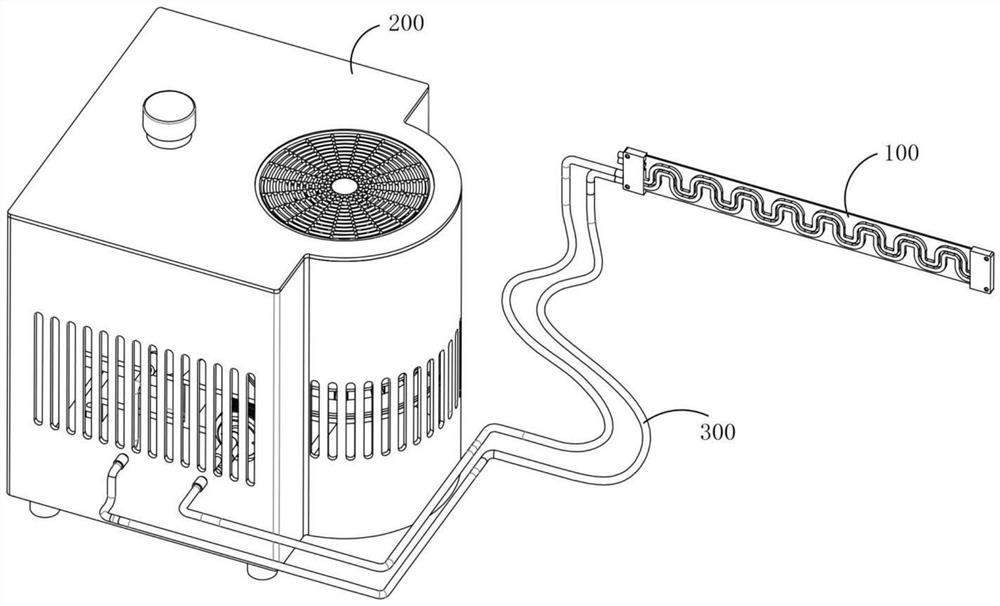

[0071] Such as Figure 1-2 , 8-9, a strip-shaped flexible circuit board square wave circulating liquid cooling device, which includes a cooling mechanism 100 and a cooling liquid supply device 200, wherein the cooling mechanism 100 is attached to the back of the flexible circuit board and adopts cooling The liquid cooling method cools the flexible circuit board. The cooling liquid required for cooling the cooling mechanism 100 is provided by the cooling liquid supply device 200 .

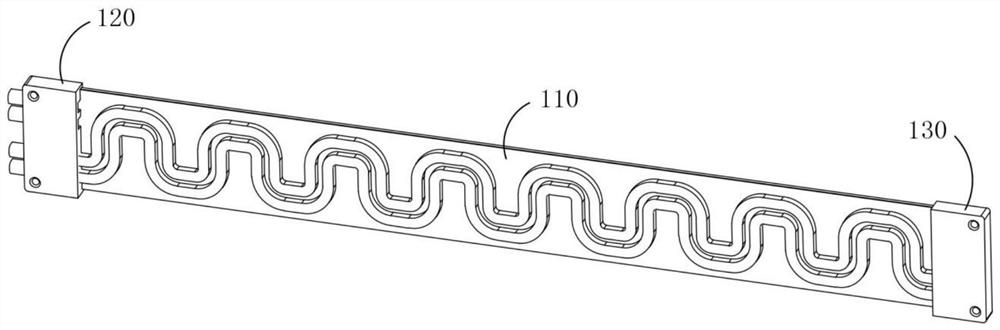

[0072] Such as Figure 4-6 As shown, the cooling mechanism 100 includes a cooling component 110 and a connection head a120 and a connection head b130 respectively dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com