Multi-runner high-speed rotating sealing device capable of conveying hard powder

A high-speed rotating and sealing device technology, which is applied in the direction of improving process efficiency, improving energy efficiency, and additive manufacturing, and can solve problems such as the inability of the laser head to rotate, process, and limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

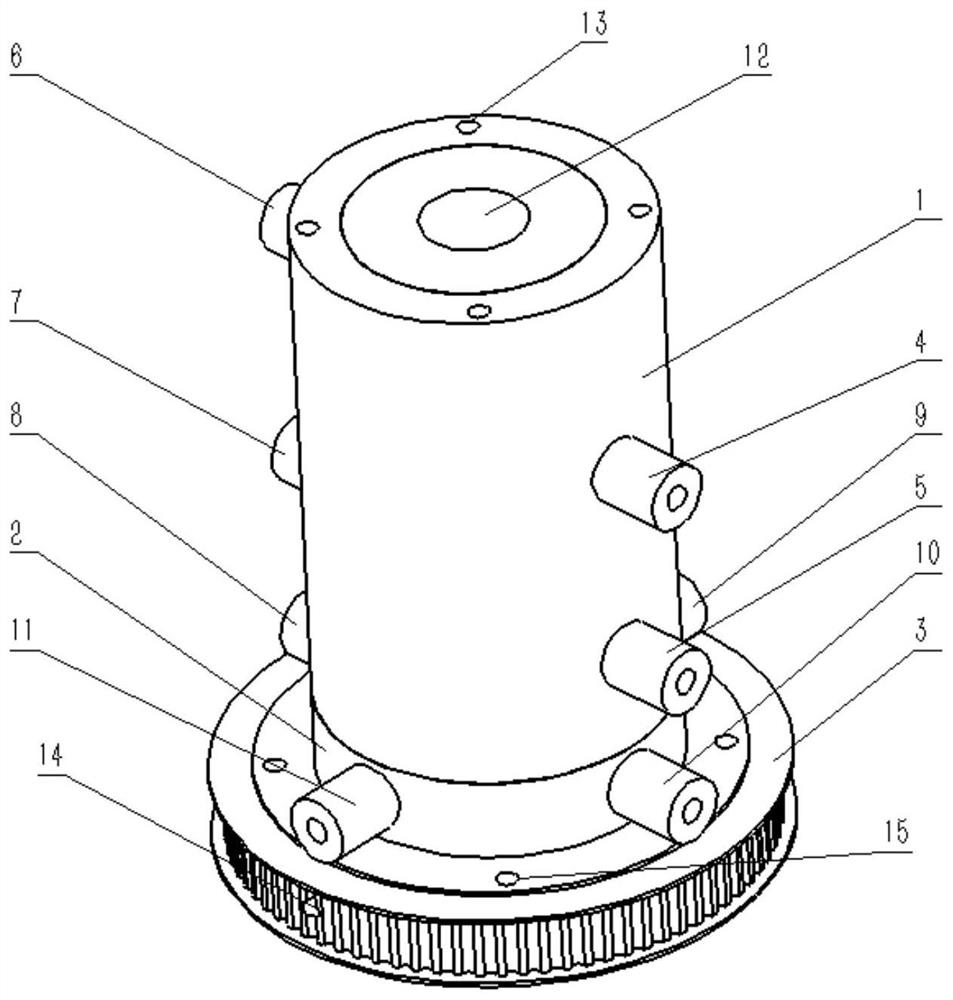

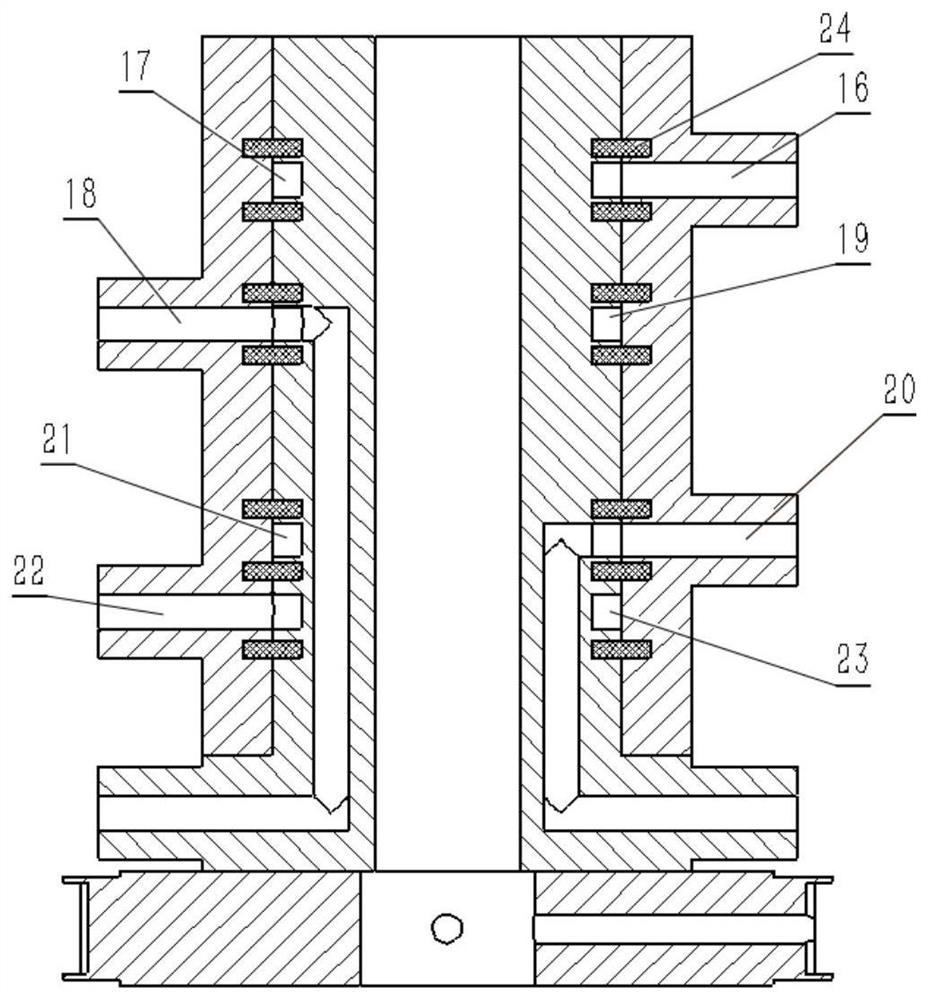

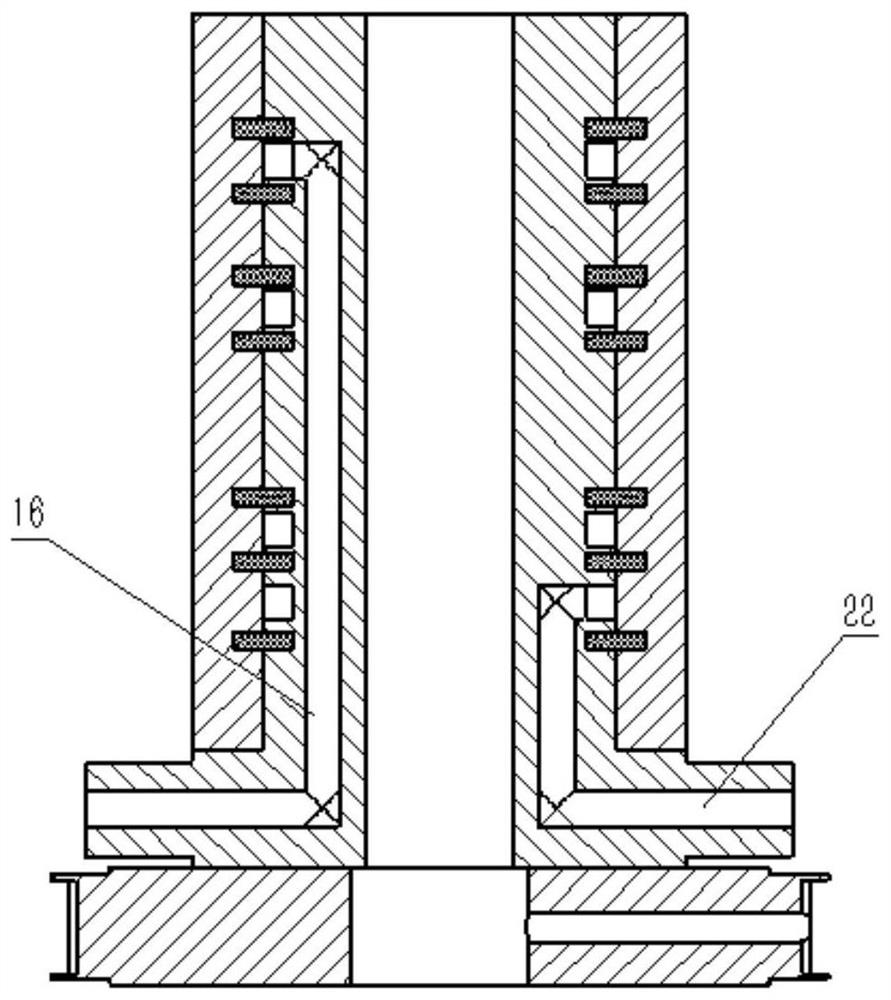

[0023] Such as 1, figure 2 As shown, the multi-channel high-speed rotary sealing device of the present invention includes a stator 1, a rotor 2, and a synchronous wheel 3 driven and rotated by a stepping motor. The stator 1 and the rotor 2 are two hollow circular shafts, the 12 laser beam channels can pass through the laser beam during laser processing, the stator 1 is fixed on the base plate through the stator fixing screw hole 13, and the rotor 2 is fixed on the step through the rotor fixing screw hole 14 On the 3 synchronous wheels rotating at high speed driven by the motor.

[0024] In the case of stator 1 and rotor 2 rotating at a relatively high speed, the laser head can achieve multi-channel, stable delivery of various substances including hard powder, mainly relying on the path design of each channel and the handover between stator 1 and rotor 2 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com