Full-automatic numerical control thread grinding machine

A thread grinding machine, fully automatic technology, applied in the direction of grinding machine parts, grinding/polishing equipment, abrasive surface adjustment devices, etc., can solve the problems of heavy relief grinding load, difficult to guarantee life and accuracy, and achieve good processing quality. , the effect of small vibration and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

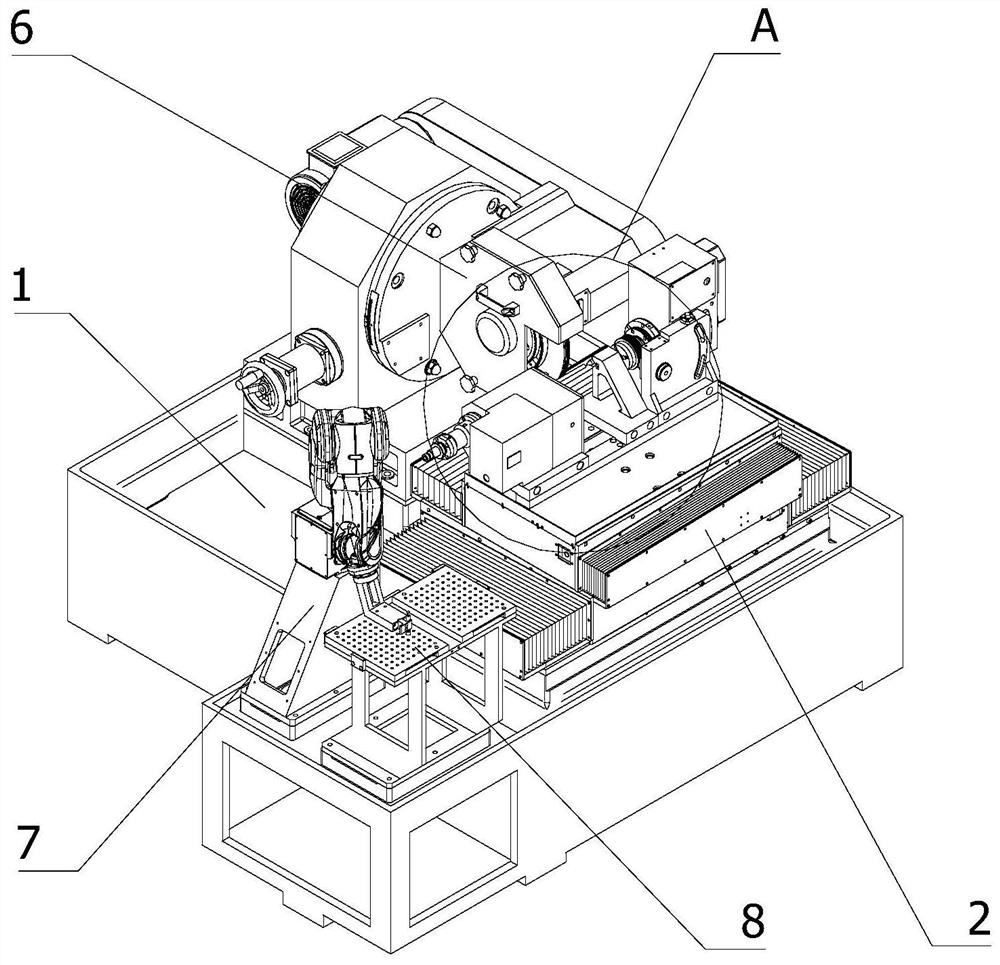

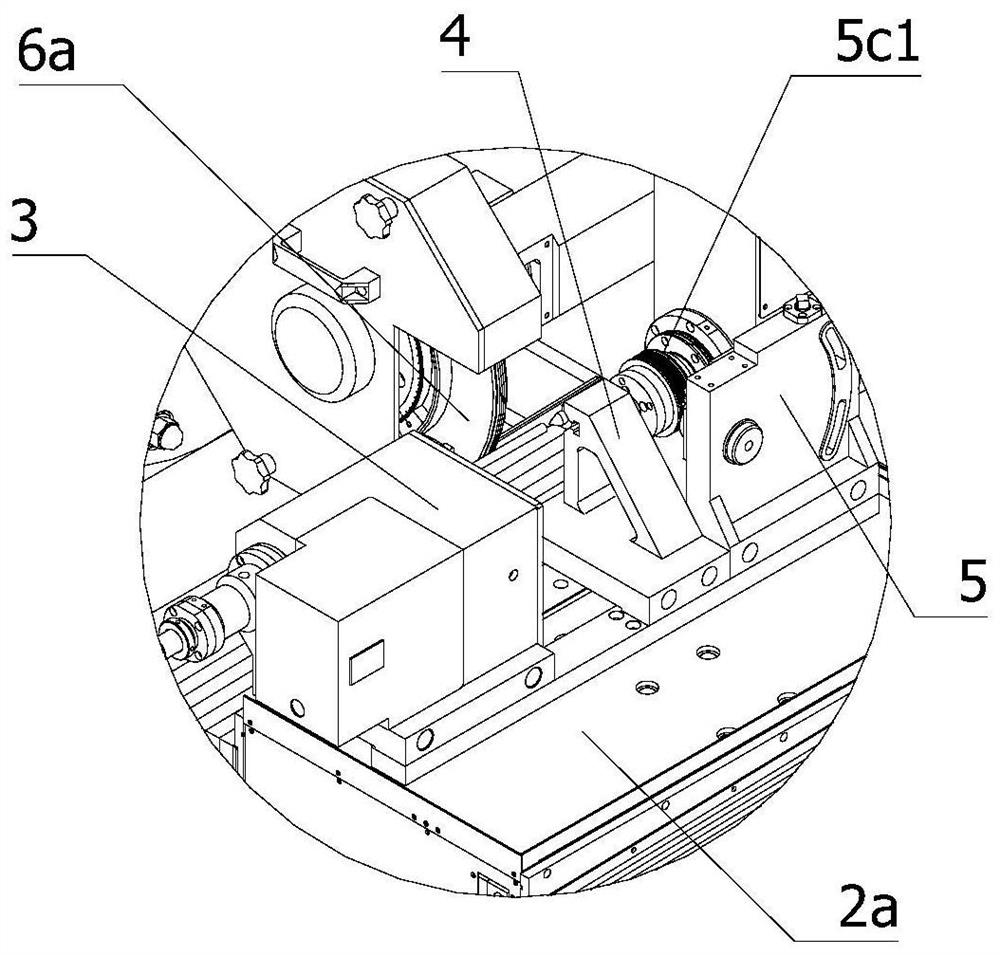

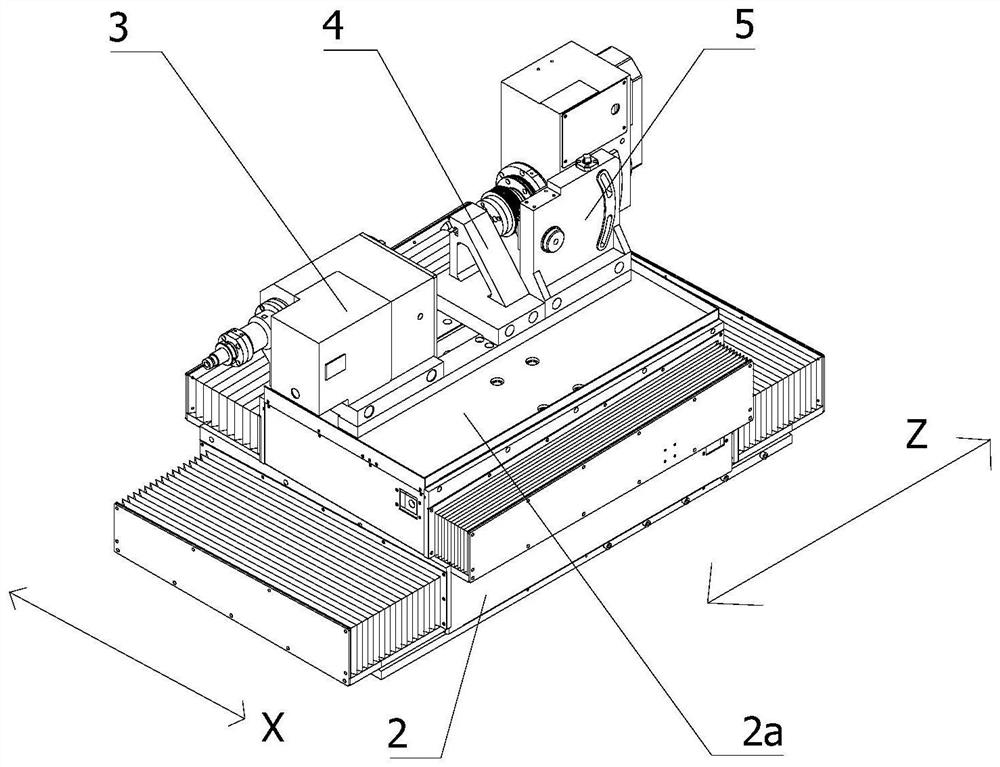

[0070] In order to solve the problem that when the grinding wheel is shoveling the workpiece, the feeding of the grinding wheel will generate large vibrations, resulting in vibration lines on the surface of the tap thread, inconsistent diameters, and the frequency of the shoveling of the grinding wheel is low, and the production speed is slow. technical issues such as figure 1 , 2 , 3, 4, 5, and 6, the following preferred technical solutions are provided:

[0071] A fully automatic CNC thread grinding machine, including a frame 1, a grinding head device 6 fixedly installed on the frame, a workpiece spindle 3 and a tailstock 4,

[0072] Grinding wheel 6a is arranged on the grinding head device 6; a movabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com