Numerical-control cutting machine tool for metal plate machining and using method

A technology for cutting machine tools and sheet metal, which is applied in the field of CNC cutting machine tools for sheet metal processing, can solve problems such as unusable sheets, and achieve the effect of enhancing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

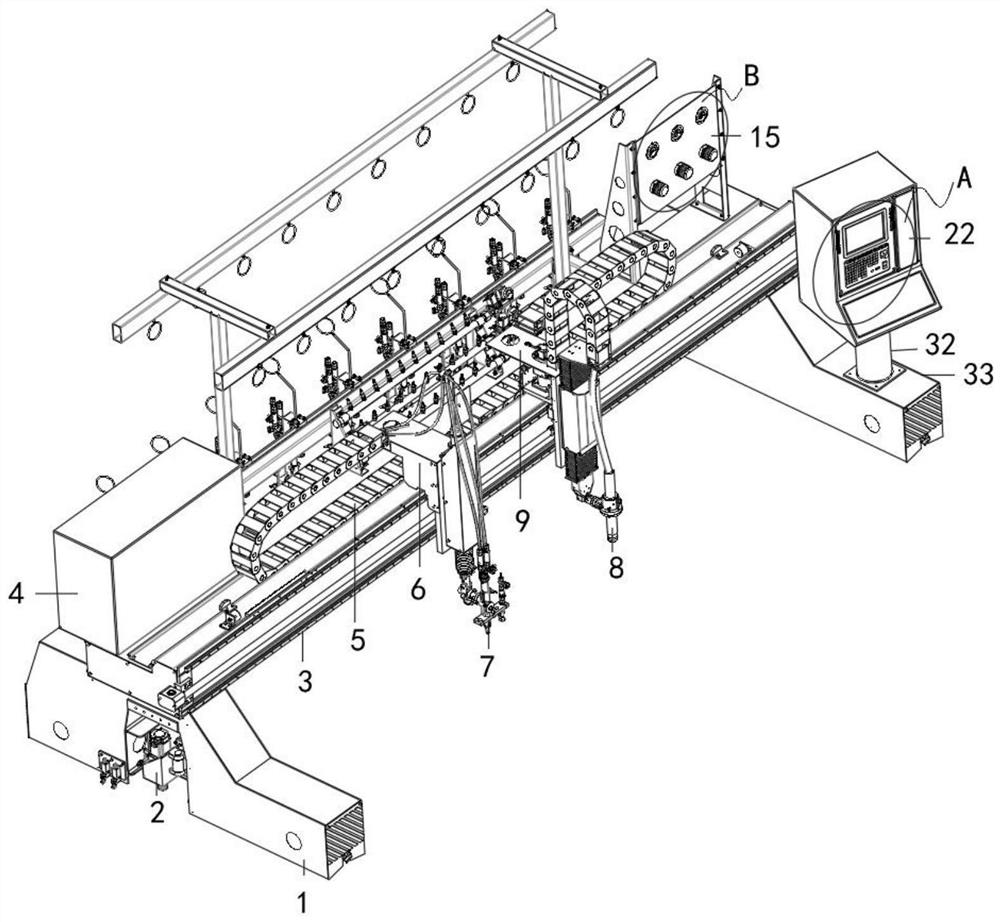

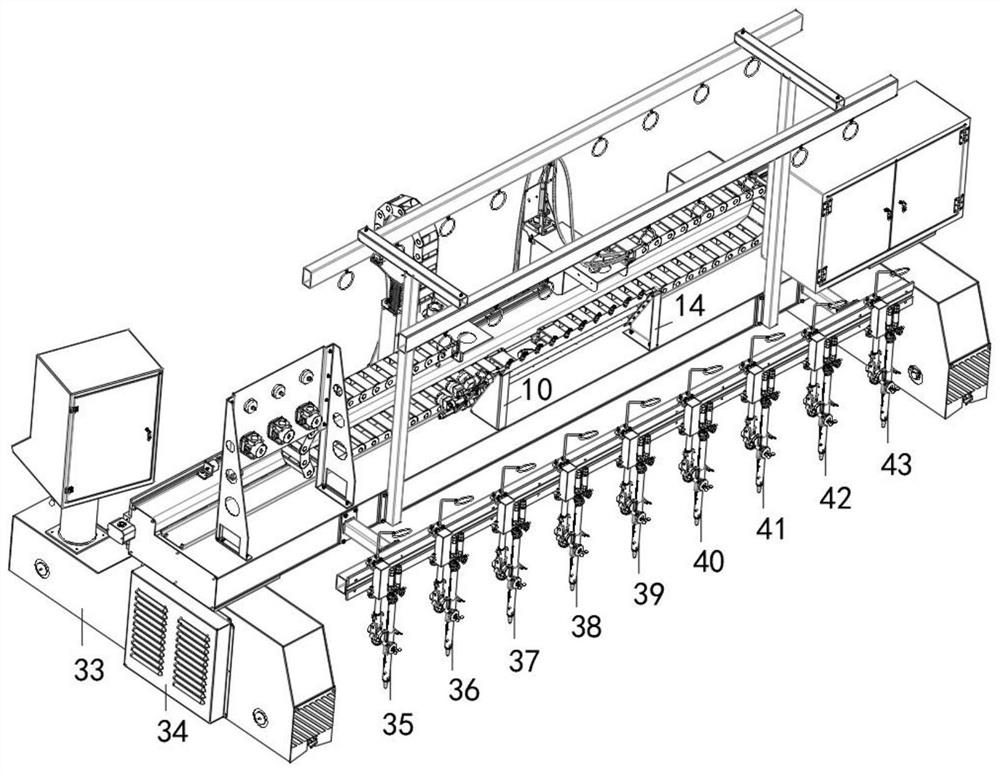

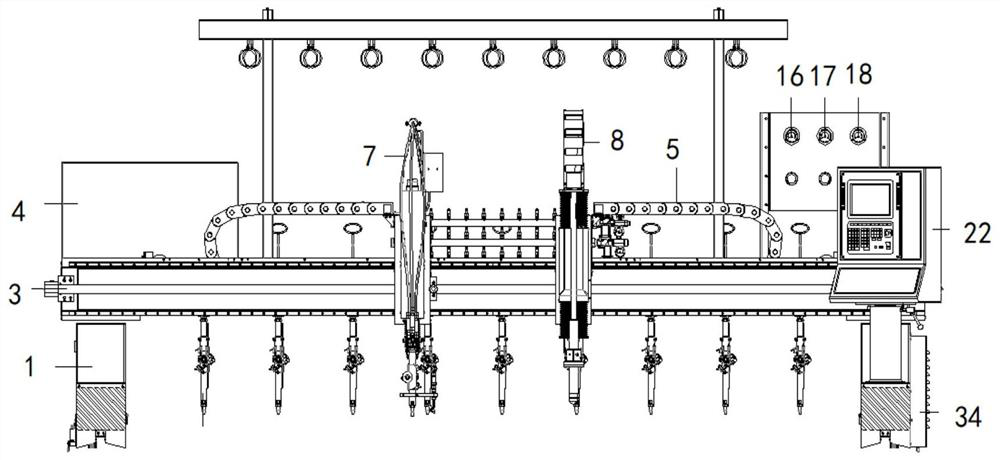

[0040] like Figure 1-10 As shown, the CNC cutting machine tool for metal plate processing includes a first base 1, a drive motor 2 is installed inside the first base 1, and a connecting frame 3 is connected to the upper end of the first base 1, and one end of the connecting frame 3 is connected to a Power supply box 4, and the power supply box 4 has played the role of power supply, so that the whole CNC cutting machine tool starts to run, the first chain 5 is installed on one side of the power supply box 4, and one end of the first chain 5 is connected with the first L-shaped connecting plate 6. One side of the first L-shaped connecting plate 6 is connected with an arc cutting mechanism 7, and one side of the arc cutting mechanism 7 is equipped with a punching mechanism 8, and the punching mechanism 8 plays a punching role, and one part of the punching mechanism 8 The side is connected with the second L-shaped connecting plate 9, the other end of the second L-shaped connectin...

Embodiment 2

[0050] The method of using a CNC cutting machine tool for metal sheet processing, the steps of the method are as follows:

[0051] Step 1: After first turning on the power, press the switch button 25 to allow the power supply box 4 to start supplying power to the inside of the CNC cutting machine tool. At this time, press the drive motor switch button 28 to allow the drive motor 2 to start running, and the drive motor 2 Starting to run will drive the vacuum cleaner 34 to start running, so that the entire CNC cutting machine tool starts running, and then take out the plate to be processed and place it directly below the arc cutting mechanism 7, and then insert the USB into the USB interface 26 to cut the shape. The graphics are transmitted to the console 22, and then the movement of the first chain 5 on the track 3002 is controlled in the chain control key 29, and the movement of the first chain 5 will drive the movement of the arc cutting mechanism 7 until the arc cutting mecha...

Embodiment 3

[0058] After first turning on the power supply, press the switch button 25 to allow the power box 4 to start supplying power to the inside of the CNC cutting machine tool. At this time, press the drive motor switch button 28 to allow the drive motor 2 to start running, and the start of the drive motor 2 will be Drive the vacuum cleaner 34 to start running, and the vacuum cleaner 34 has played the role of dust suction, and at the same time played a role in protecting the environment to a certain extent, so that the entire CNC cutting machine tool starts to run, and then the plates to be processed are taken out and placed on the arc directly below the cutting mechanism 7, then insert the USB into the USB interface 26 so that the graphics that need to be cut and shaped are transmitted to the console 22, and then control the movement of the first chain 5 on the track 3002 in the chain control key 29, and along with The movement of the first chain 5 will drive the movement of the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com