A precision numerical control machine tool for hardware processing

A precision numerical control and hardware technology, applied in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve problems such as waste of resources, collision between milling cutters and splints, and high consumption of lubricating oil, saving production costs, Smooth processing and solid-liquid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

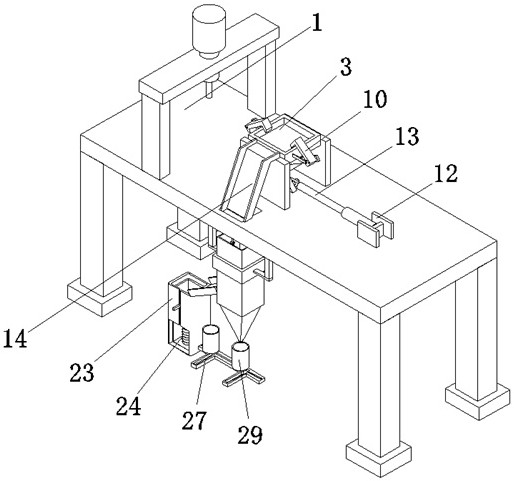

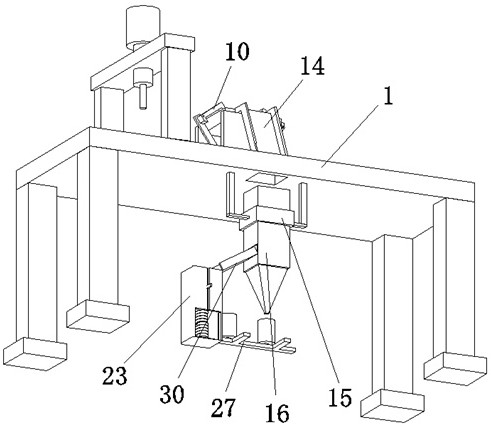

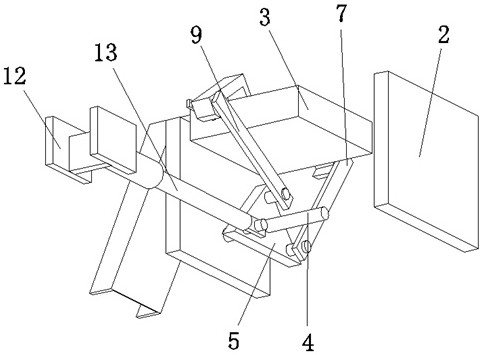

[0022] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

[0023] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7, the present invention provides a technical solution: a precision CNC machine tool for hardware processing, including a processing table 1, through the through groove opened on the front side of the upper surface of the processing table 1, the hardware debris can be easily introduced into the In the filter box 16, it plays the role of preparing for the solid-liquid separation of the metal chips condensed with the lubricating oil. A fixed table 3 is fixedly installed on the upper side, a rotating shaft 4 is movably sleeved in the middle part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com