Belt clamping conveying mechanism and subpackaging machine using same

A technology of conveying mechanism and subcontracting machine, which is applied in the direction of conveyor, transportation and packaging, packaging, etc., can solve the problems of inability to achieve manual packaging, reduced friction between packaging boxes and conveyor belts, and inability to accurately control feeding, etc., to ensure stable, Prevent deviation and ensure the effect of running

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

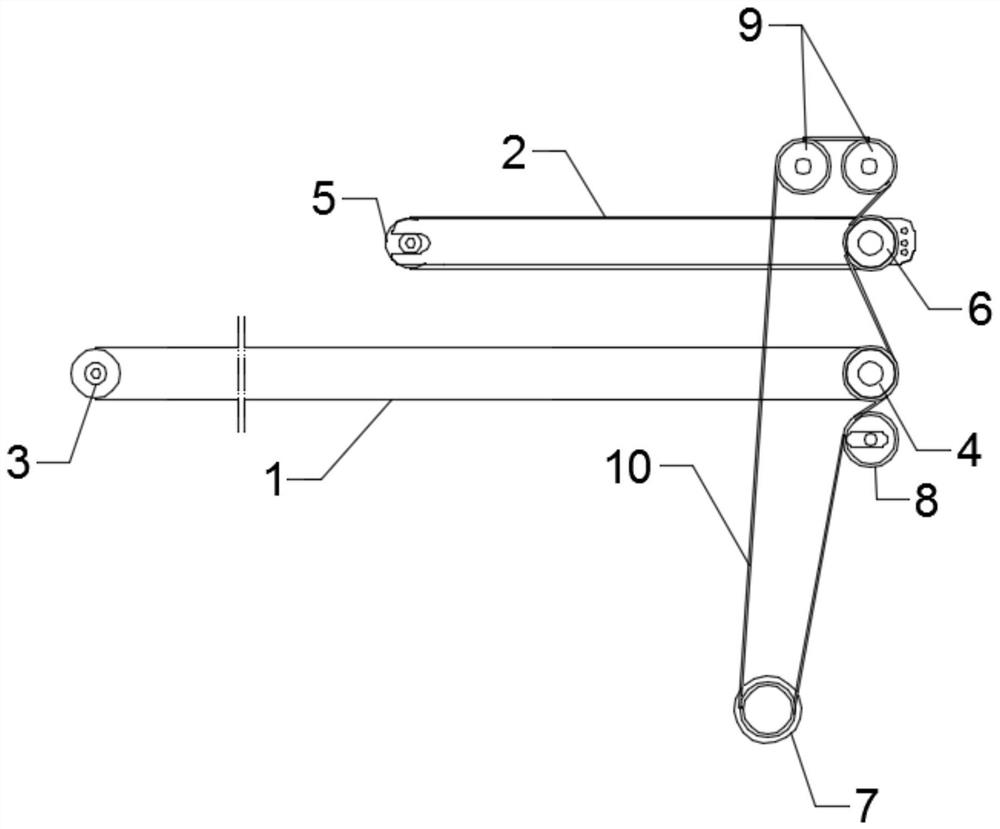

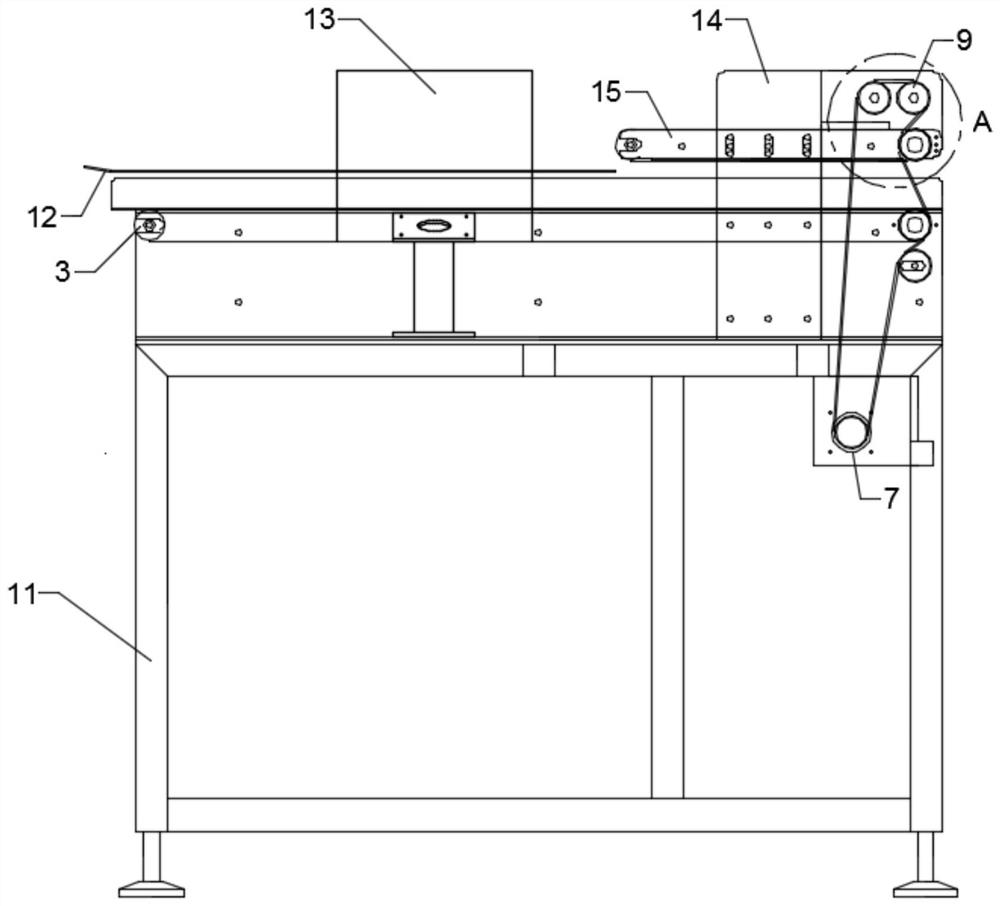

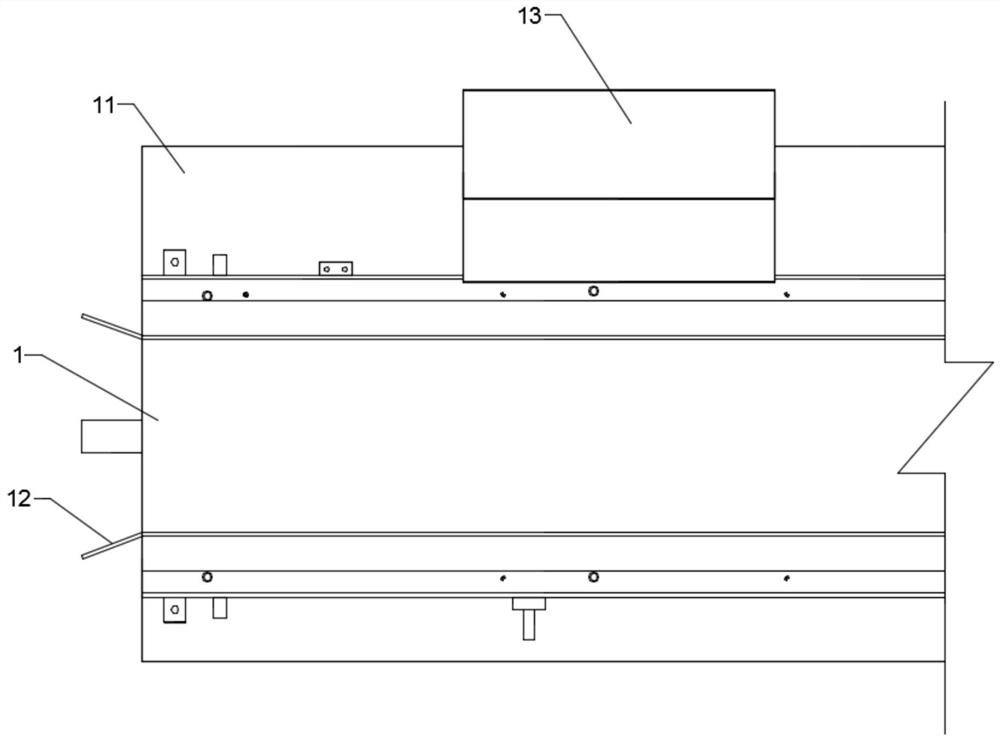

[0032] Such as Figure 1 to Figure 5As shown, the present invention discloses a belt clamping transmission mechanism. The adopted technical solution is to include a lower conveyor belt 1, an upper conveyor belt 2, a lower driven roller 3, a lower driving roller, an upper driven roller 5, an upper driving roller, Drive pulley 7, tension pulley 8 and stretching pulley 9, described lower conveyor belt 1 is sleeved on described lower driven roller 3 and described lower driving roller, and lower driving pulley 4 is housed on described lower driving roller, and described upper The conveyor belt 2 is sleeved on the upper driven roller 5 and the upper driving roller, the upper driving roller is equipped with an upper driving wheel 6, the driving wheel 7 is connected to the servo motor through a reducer, the driving wheel 7, the expansion The tightening wheel 8, the lower driving wheel 4, the upper driving wheel 6 and the stretching wheel 9 are located on the same vertical surface and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com