Method and device for supplementing molten carbonate fuel cell electrolyte

A molten carbonate and fuel cell technology, applied in molten electrolyte fuel cells, fuel cell additives, fuel cell control, etc., can solve problems such as damage to the battery structure, and achieve the effect of avoiding time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

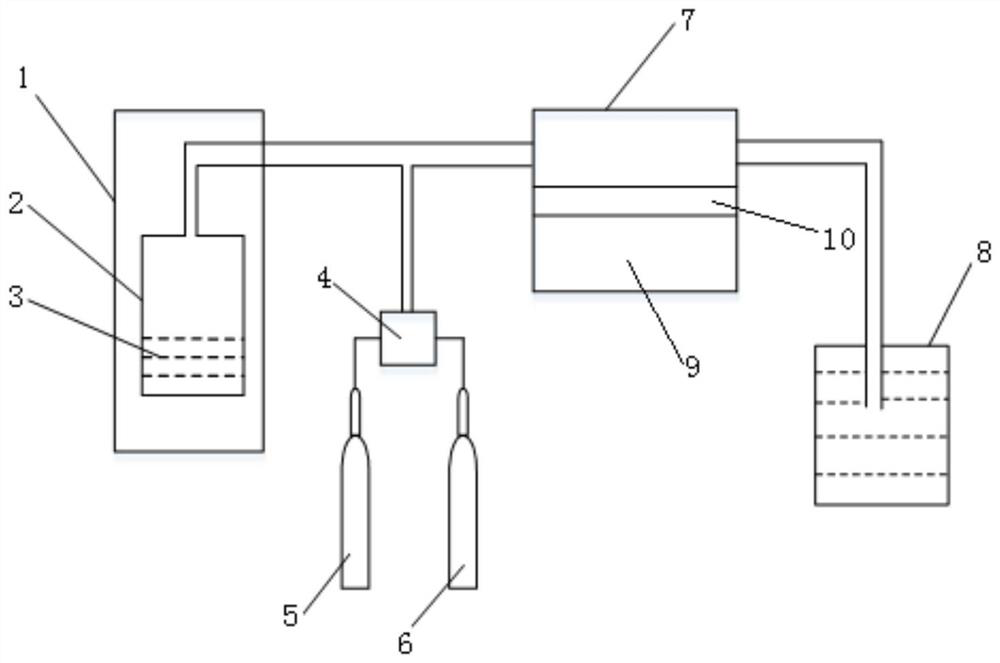

Method used

Image

Examples

Embodiment 1

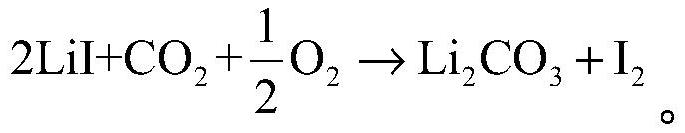

[0037] This embodiment provides a method for supplementing molten carbonate fuel cell electrolyte, the specific steps are as follows:

[0038] Heat lithium iodide to 520°C to form steam;

[0039] Carbon dioxide and oxygen are heated to 520°C, and the above steam is passed into the cathode chamber of the molten carbonate fuel cell at the same time, wherein the molar ratio of lithium iodide to carbon dioxide and oxygen is 1.8:0.9:0.3, and the reaction occurs, The flow rate of carbon dioxide and oxygen was controlled at 5L / min to generate carbonate until the electrolyte replenishment was completed.

Embodiment 2

[0041] This embodiment provides a method for supplementing molten carbonate fuel cell electrolyte, the specific steps are as follows:

[0042] Heat lithium iodide to 550°C to form steam;

[0043] Heat carbon dioxide and oxygen to 550°C, and pass the above steam into the cathode chamber of the molten carbonate fuel cell at the same time, in which the molar ratio of lithium iodide to carbon dioxide and oxygen is 2:1:0.5, and react to form carbon acid salt, wherein the flow rate of carbon dioxide and oxygen is controlled at 6L / min until the electrolyte replenishment is completed, and the unreacted raw materials and the generated halide vapor are cooled and recycled.

Embodiment 3

[0045] This embodiment provides a method for supplementing molten carbonate fuel cell electrolyte, the specific steps are as follows:

[0046] Heat lithium iodide to 600°C to form steam;

[0047] Carbon dioxide and oxygen are heated to 600°C, and the above steam is passed into the cathode chamber of the molten carbonate fuel cell at the same time, wherein the molar ratio of lithium iodide to carbon dioxide and oxygen is 2.2:1.1:0.6, and the reaction occurs to form carbon acid salt, wherein the flow rate of carbon dioxide and oxygen is controlled at 7L / min until the electrolyte replenishment is completed, and the unreacted raw materials and the generated halide vapor are cooled and recycled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com