Laminated transformer type power combiner and series-parallel hybrid power combining structure

A power combiner and transformer-type technology, which is applied in the field of laminated transformer-type power combiners and series-parallel hybrid power combining structures, can solve the problems of low power combining efficiency, improve coupling coefficient, improve power combining efficiency, reduce Effect of Power Combining Loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

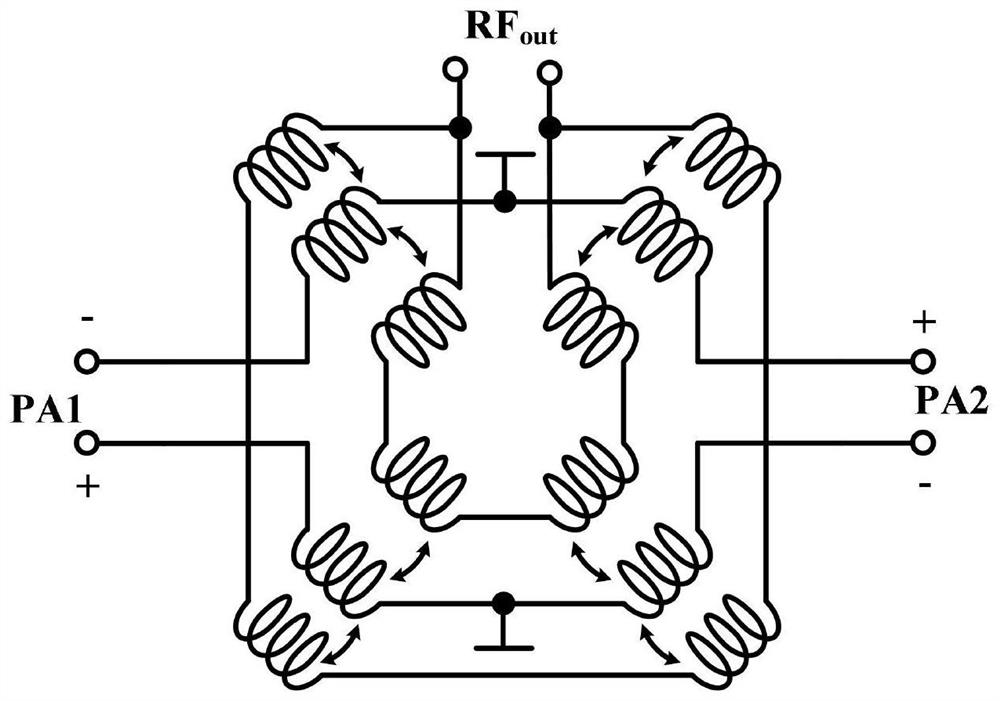

[0043] An embodiment of the present invention provides a laminated transformer type power combiner, the combiner includes a laminated transformer, the transformer has three layers of coils, the first layer coil and the third layer coil include four identical windings, the first layer The coil and the third-layer coil are connected in parallel, and the parallel connection is connected to the output terminal; the second-layer coil includes two symmetrical first half-turns and second half-turns, and each half-turn includes two identical windings, and the windings can pass through Distributed inductance connection or direct connection (directly connected together by elongating the two ends of the winding), two symmetrical half circles are respectively coupled with the first layer coil and the third layer coil; the two ends of the first half circle respectively connect the positive pole of the first differential power amplifier output terminal and the negative pole of the second dif...

Embodiment 2

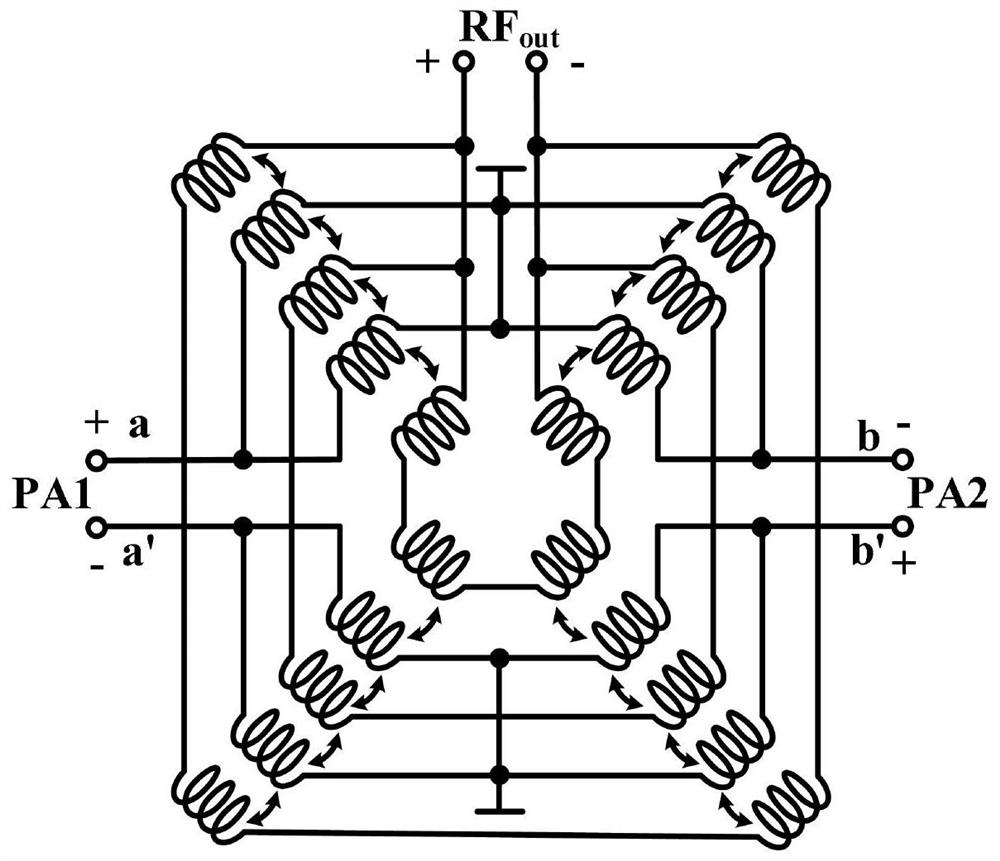

[0047] An embodiment of the present invention provides a laminated transformer-type power combiner, including a laminated transformer, wherein: the laminated transformer includes 2N-1 layer coils, where N is a natural number greater than 2; odd-numbered layer coils are connected in parallel, and Connect the output terminal; the occasional layer coils include two symmetrical first half circles and second half circles, and the two symmetrical half circles are respectively coupled to the adjacent two-layer odd-numbered layer coils; the first half circles of different even-numbered layers Connect in parallel to form connection end a and connection end b, and connect the second half-turns of different even-numbered layers in parallel to form connection end a' and connection end b'; two symmetrical half-turns are respectively coupled with two adjacent odd-numbered layer coils The connecting end a and the connecting end b are respectively connected to the positive pole of the output e...

Embodiment 3

[0050] An embodiment of the present invention provides a series-parallel hybrid power combiner structure, including a T-type parallel combiner, and two or more laminated transformer-type power combiners in Embodiment 1 or Embodiment 2, wherein the T-type The parallel combiner includes two or more sets of coupled lines with loading capacitors connected in parallel; the in-phase output ports of the coupled lines are connected to each other, and the input ports are independent of each other; the output terminals of the laminated transformer type power combiner are connected to the Input port connection of T-parallel synthesizer.

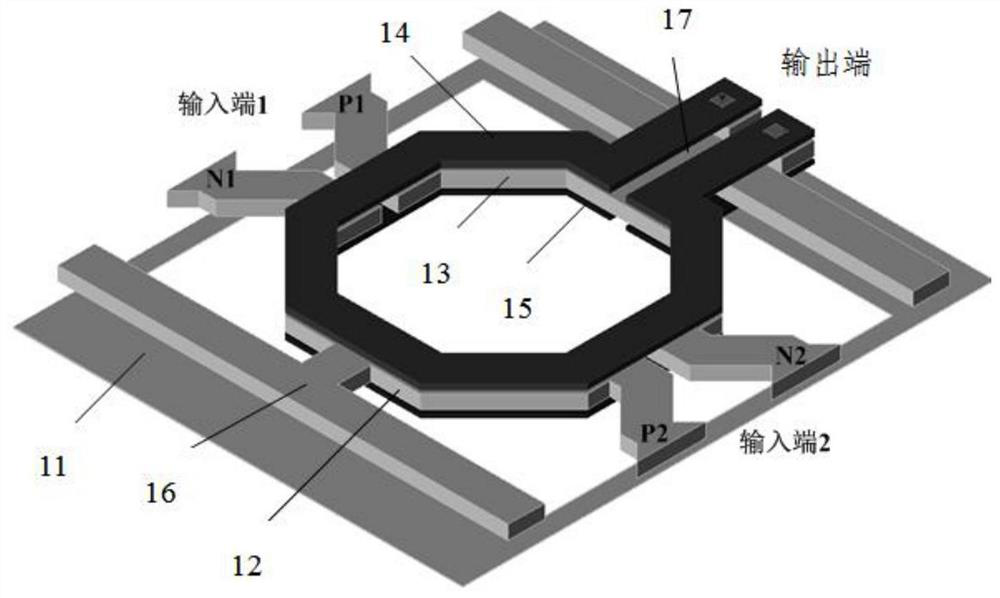

[0051] When the laminated transformer power combiner is the combiner in Embodiment 1, and the T-type parallel combiner includes two sets of coupled lines connected in parallel, the schematic diagram of the series-parallel hybrid power combiner structure is as follows Figure 4 As shown, the three-dimensional model diagram is shown in Figure 5 shown in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com