Processing technology of fast-brewing cold-brewing seasoning tea

A processing technology and technology for flavored tea, applied in the field of quick-brewing cold-brewing flavored tea processing technology, can solve the problems of inconvenient drinking, long time, poor drinking palatability, etc., and achieve fast brewing speed, improved dissolution, and bright soup color Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

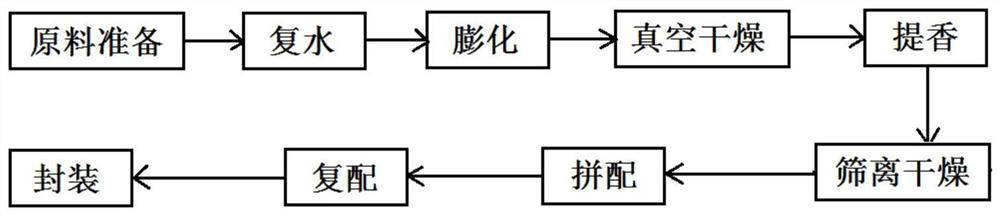

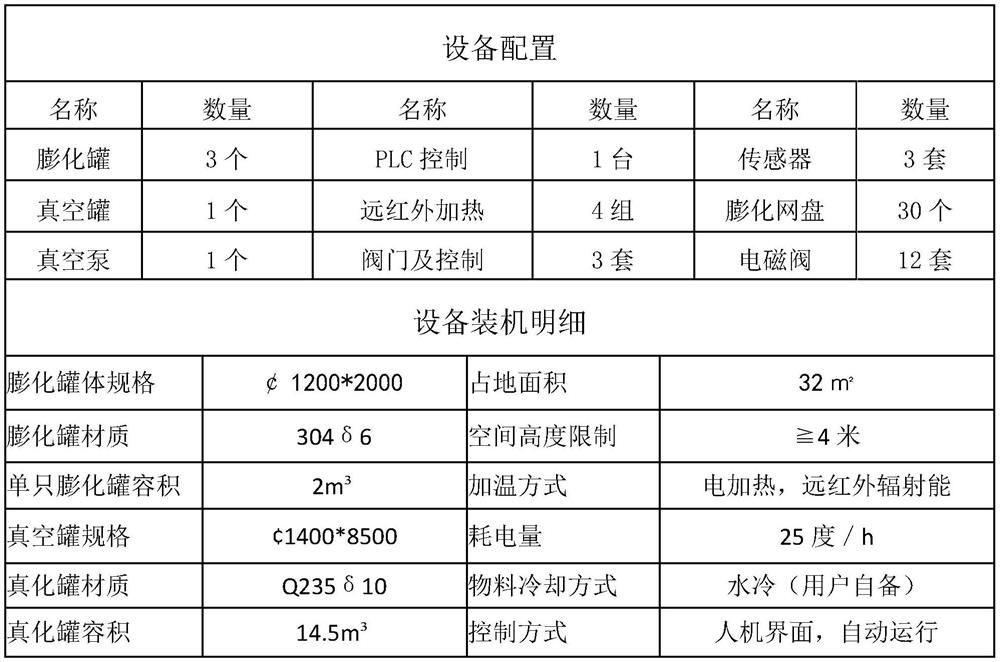

Method used

Image

Examples

experiment example 1

[0053] Experimental Example 1: Pineapple Rose Oolong Tea

[0054] Rehydration: Oolong tea rehydration to 35%;

[0055] Expansion: pressurized conditions: temperature 75°C, time 1h; puffed conditions: pressure: 250kPa, temperature: 95°C, time 5min;

[0056] Vacuum drying conditions: temperature: 60°C, vacuum rate 70%, time 2h, dry to moisture content 10%-15%;

[0057] Dice the fresh fruit and pre-cool: Peel and dice the fresh pineapple, put it in the freezer at -20°C for 2 hours for later use, and refrigerate the fresh rose petals at 4°C for later use;

[0058] Stirring: Oolong tea, pre-cooled fresh diced pineapple, and fresh rose petals are fully mixed according to the mass ratio of 2:3:1, put into a fragrant bag, and seal.

[0059] Titian: Place in the fragrance room to enhance the fragrance. Conditions for fragrance: 25°C, 1h, 40°C, 2h, 60°C, 2h, and then put the fragrance bag in a 4°C refrigerator for 12h to fully integrate the aroma in the material adsorption.

[0060]...

experiment example 2

[0063] Experimental example 2: Osmanthus orange white tea

[0064] Rehydration: White tea rehydrates to 30%.

[0065] Expansion: pressurized conditions: temperature 65°C, time 1h; puffed conditions: pressure: 250kPa, temperature: 95°C, time 3min;

[0066] Vacuum drying conditions: temperature: 60°C, vacuum rate 70%, time 2h, dry to moisture content 10%-15%;

[0067] Fresh fruit dicing and pre-cooling: After washing the oranges, cut them into cubes together with the peel, and put them in a refrigerator at -20°C for 2 hours for later use. Refrigerate fresh osmanthus flowers at 4°C for later use;

[0068] Stirring: White tea, pre-cooled fresh diced oranges, and fresh osmanthus are fully mixed according to the mass ratio of 2:1:0.2, put into a fragrant bag, and seal.

[0069] Titian: Place in the fragrance room to enhance the fragrance. Conditions for fragrance: 25°C, 1h, 40°C, 2h, 60°C, 2h, and then put the fragrance bag in a 4°C refrigerator for 12h to fully integrate the arom...

experiment example 3

[0074] Experimental Example 3: White Peach Jasmine Green Tea

[0075] Rehydration: Green tea rehydration to 30%.

[0076] Expansion: pressurized conditions: temperature 65°C, time 1h; puffed conditions: pressure: 250kPa, temperature: 95°C, time 3min;

[0077] Vacuum drying conditions: temperature: 60°C, vacuum rate 70%, time 2h, dry to moisture content 10%-15%;

[0078] Fresh fruit dicing and pre-cooling: Ripe peaches are washed and diced, placed in a refrigerator at -20°C for 2 hours for later use, and fresh jasmine flowers are refrigerated at 4°C for later use;

[0079] Stirring: Green tea, pre-cooled fresh peach dices, and fresh jasmine are fully mixed according to the mass ratio of 2:1:1, put into a fragrance bag, and seal.

[0080] Titian: Place in the fragrance room to enhance the fragrance. Conditions for fragrance: 25°C, 1h, 40°C, 2h, 60°C, 2h, and then put the fragrance bag in a 4°C refrigerator for 12h to fully integrate the aroma in the material adsorption.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com