Mung bean paste tobacco tar and preparation method thereof

A technology for mung bean paste and mung bean, which is applied in the directions of tobacco, tobacco processing, application, etc., can solve the problems of low mung bean aroma reduction degree, difficult to meet the needs of smokers, etc., and achieves the effect of enhancing the sense of satisfaction and improving the reduction degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

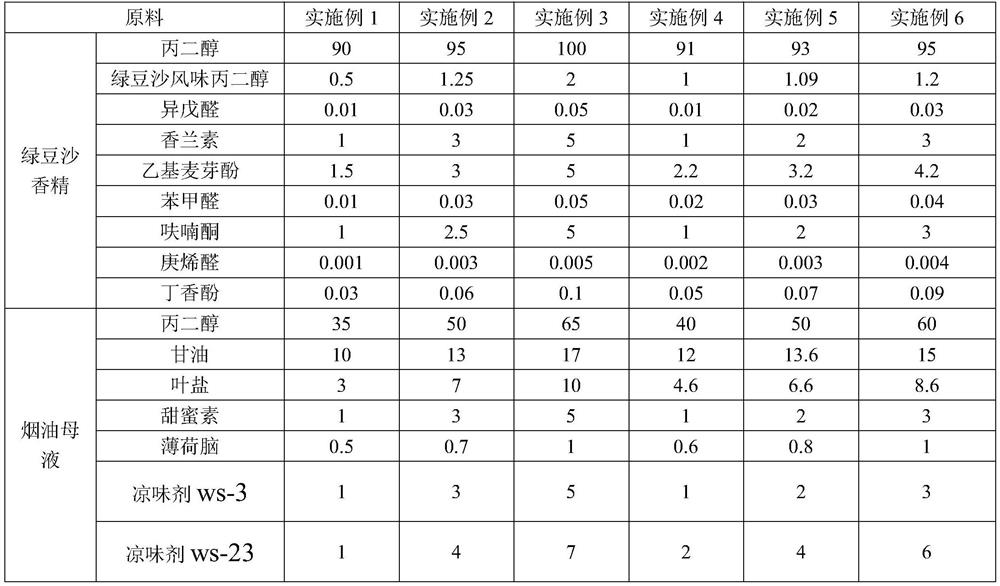

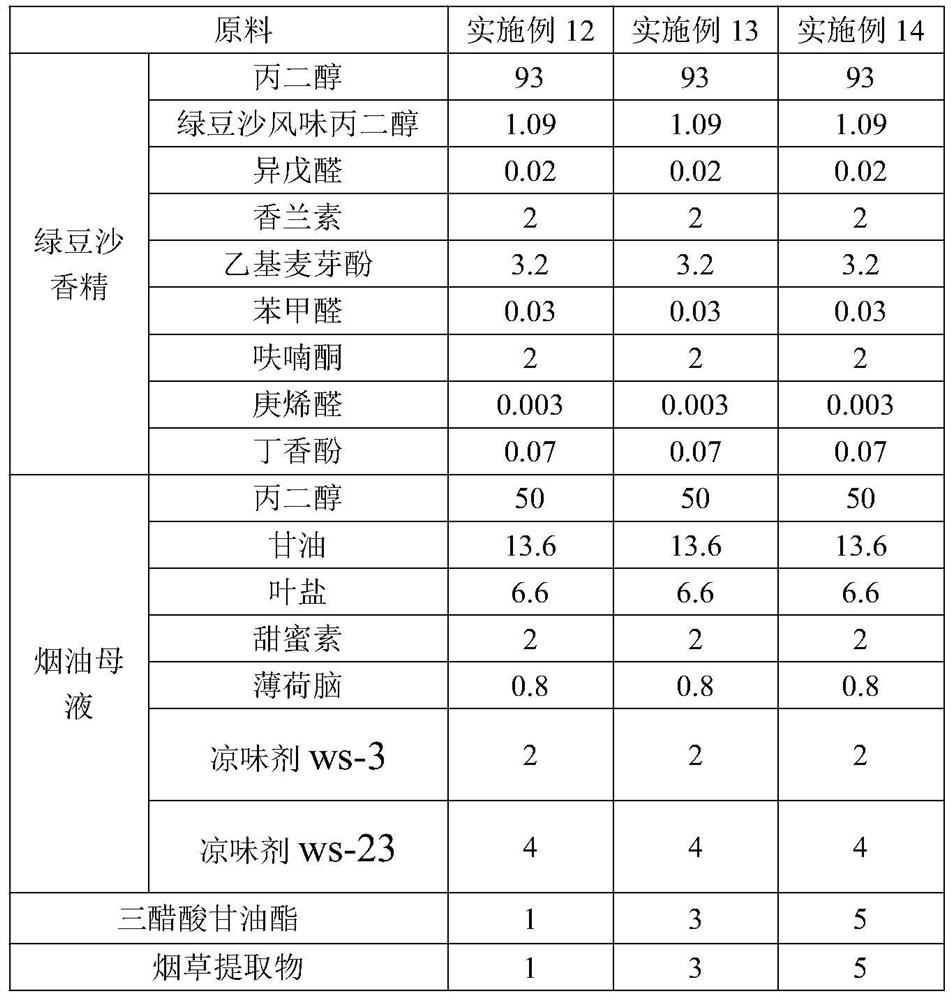

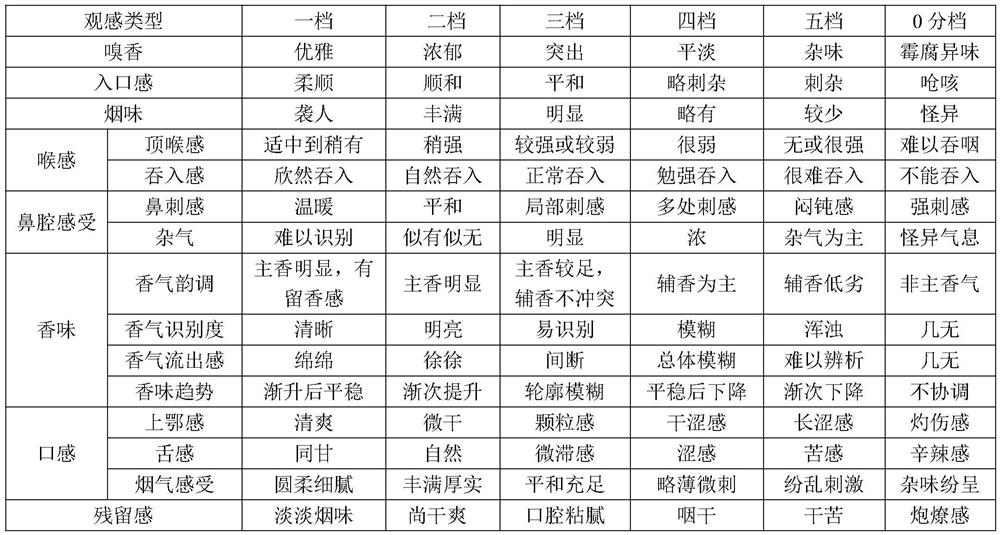

Examples

preparation example 1

[0044] A mung bean paste flavor propylene glycol, which is prepared by the following method:

[0045] S1: crush 90g mung beans, and collect mung bean puree;

[0046] S2: Mix mung bean paste with 630ml of phosphate buffer solution with a pH of 8, raise the temperature to 50°C, add 0.9ml of bromelain, and enzymatically hydrolyze the mung bean paste for 1.5 hours;

[0047] S3: The enzymatically hydrolyzed mung bean puree was inactivated at 85° C. for 8 minutes, then cooled, and centrifuged at 3000 r / min for 10 minutes to obtain a supernatant that was the mung bean enzymatic hydrolyzate.

[0048] S4: Mix 100g of mung bean enzymatic hydrolysis solution, 50ml of glucose and 15ml of phosphate buffer, mix and stir evenly, and react at 90°C for 15min, then add 3ml of propylene glycol for extraction, and take an organic solvent after separation to obtain mung bean Sand flavored propylene glycol.

preparation example 2

[0050] A mung bean paste flavor propylene glycol, which is prepared by the following method:

[0051] S1: crush 100g mung beans, and collect mung bean paste;

[0052] S2: Mix mung bean paste with 850ml of phosphate buffer solution with a pH of 8.2, raise the temperature to 55°C, add 1.5ml of bromelain, and enzymatically hydrolyze the mung bean paste for 2 hours;

[0053] S3: The mung bean paste after enzymolysis was inactivated at 90°C for 12 minutes, then cooled, and centrifuged at 4000r / min for 15 minutes to obtain a supernatant that was the mung bean enzymatic hydrolysis solution.

[0054] S4: Mix 100g of mung bean enzymatic hydrolysis solution, 50ml of glucose and 20ml of phosphate buffer and stir evenly, and react at 110°C for 20min, then add 5ml of propylene glycol for extraction, and take an organic solvent after separation to obtain mung bean Sand flavored propylene glycol.

preparation example 3

[0056] A mung bean paste flavor propylene glycol, which is prepared by the following method:

[0057] S1: crush 110g mung beans, and collect mung bean paste;

[0058] S2: Mix mung bean paste with 1100ml of phosphate buffer solution with a pH of 8.5, raise the temperature to 60°C, add 2ml of bromelain, and enzymolyze the mung bean paste for 2.5 hours;

[0059] S3: The enzymatically hydrolyzed mung bean puree was inactivated at 95°C for 15 minutes, then cooled, and centrifuged at 5000r / min for 205min, and the obtained supernatant was the mung bean enzymatic hydrolyzate.

[0060] S4: Mix 100g of mung bean enzymatic hydrolysis solution, 50ml of glucose and 25ml of phosphate buffer, mix and stir evenly, and react at 120°C for 25min, then add 7ml of propylene glycol for extraction, and take an organic solvent after separation to obtain mung bean Sand flavored propylene glycol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com