Single-cylinder injection parallel double-color injection table structure

A single-cylinder, injection platform technology, applied in the field of single-cylinder injection parallel double-color injection platform structure, can solve the problems of easy oil leakage, accelerated oil deterioration, damage to hydraulic oil valves, etc., and achieve good sealing and no oil leakage life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

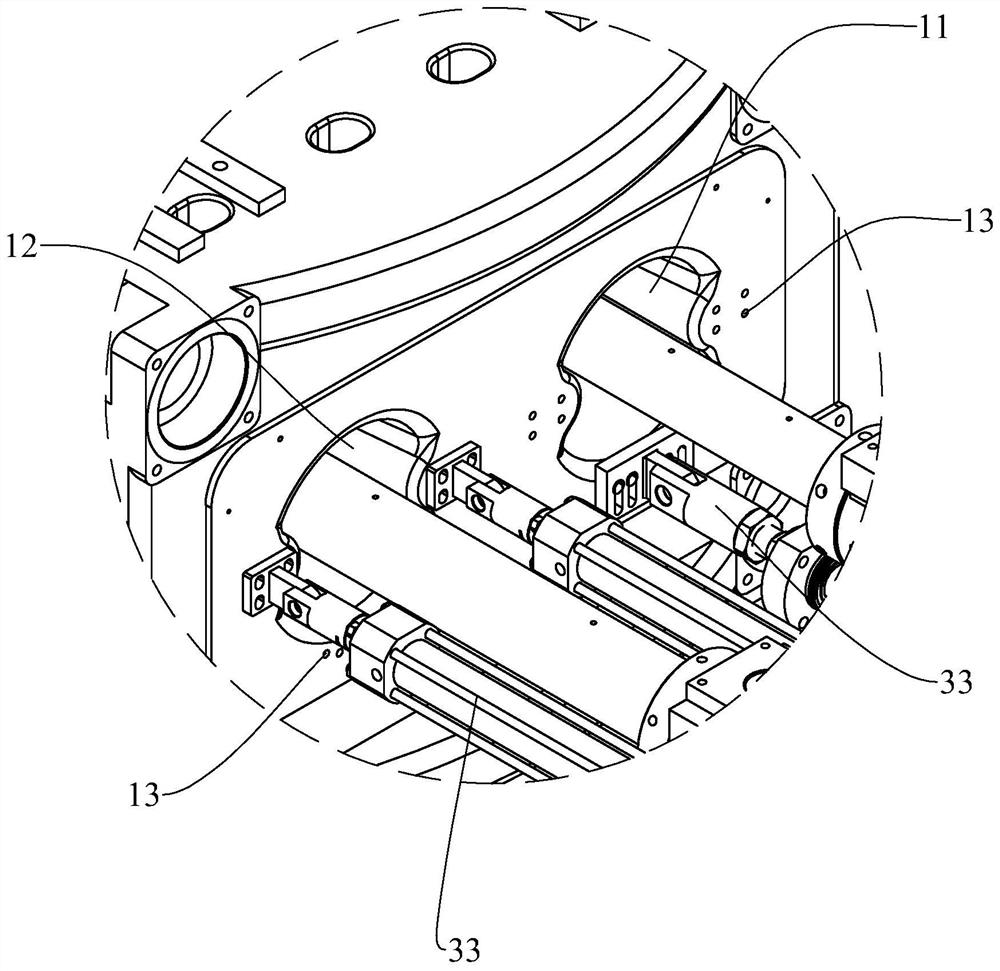

[0028] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

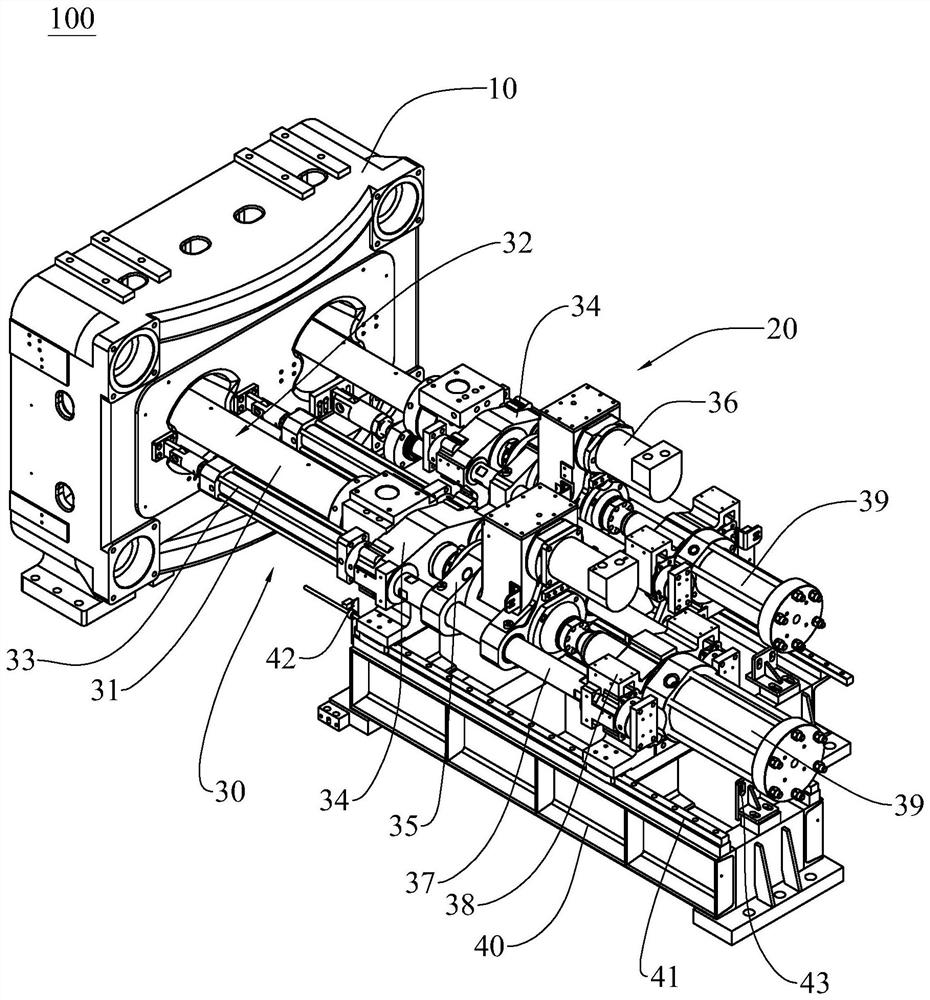

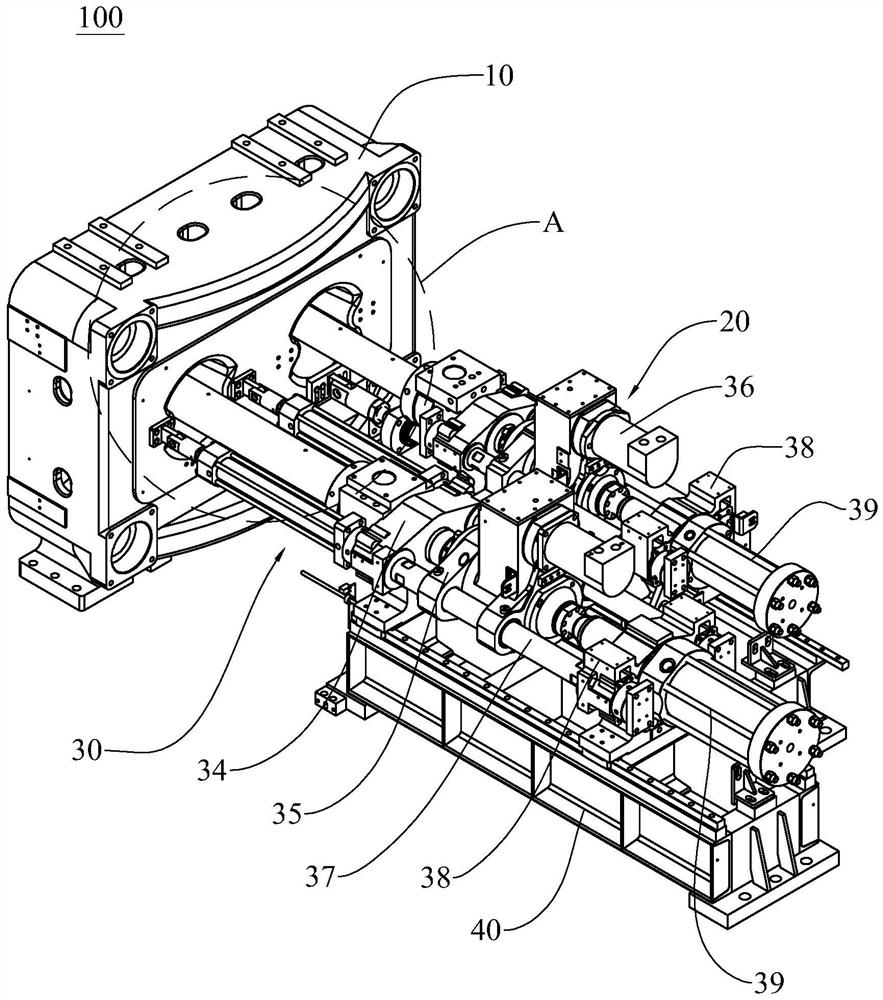

[0029] see figure 1 and figure 2 , the present invention provides a single-cylinder injection parallel two-color injection platform structure 100, which can be applied to parallel two-color injection molding machines to realize two-material two-color injection molding; it can also be applied to ordinary single-color injection molding machines. The single-cylinder injection parallel two-color injection station structure 100 includes a fixed template 10 and a first injection station 20 and / or a second injection station 30 . The first shooting station 20, the second shooting station 30, or both the first shooting station 20 and the second shooting station 30 may be provided according to actual production needs. Wherein, the installation positions of the first sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com