A glass cutting and feeding system

A glass cutting and glass technology, which is applied in the field of glass cutting and feeding system, can solve the problems of broken glass plate and transmission wheel, glass broken, difficult to control, etc., and achieve the effect of desorption, avoiding fragmentation and avoiding collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

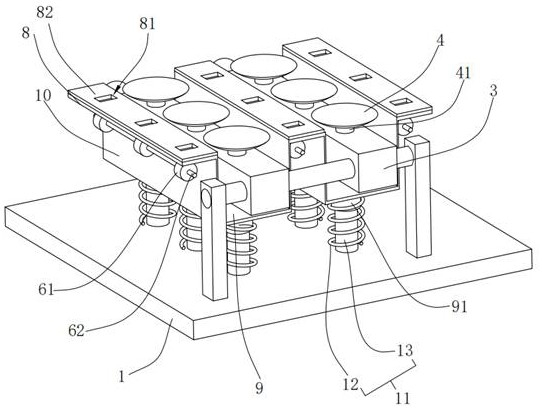

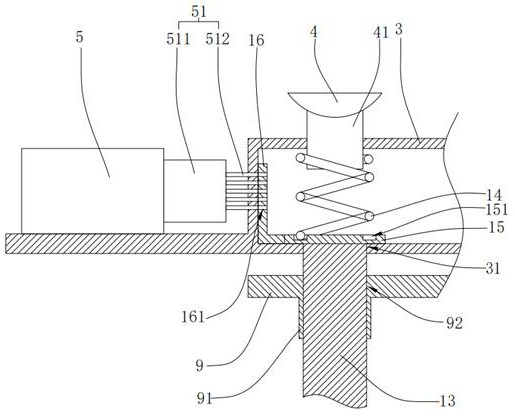

[0024] Such as figure 1 and figure 2 As shown, a glass cutting and feeding system includes a trolley 1, a glass turning mechanism and a glass transmission mechanism, wherein the structure of the trolley 1, the rotating structure in the glass turning mechanism and the glass transmission mechanism can all adopt the same structure as the prior art , so it will not be repeated in this embodiment.

[0025] Also installed on the trolley 1 is an elevating support mechanism for buffering the impact force when the glass is in contact with the transmission wheel 61. The elevating support mechanism includes a support plate 8 above the transmission shaft 62, an elevating plate 9 between the transmission shafts 62 and a supporting lifting mechanism. The elastic support assembly 11 of the plate 9, wherein the upper end of the support plate 8 is pasted with a layer of sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com