Ammonia synthesis tower for cascade recovery of waste heat and renewable energy source ammonia synthesis system

A ammonia synthesis tower and cascaded recovery technology, which is applied in energy input, ammonia compounds, climate sustainability, etc., can solve the problems that the reaction temperature does not match the optimum temperature, the reactor temperature is uneven, and the equipment process is complex, etc., to achieve high efficiency Effects of heat transfer, high energy efficiency, and simplified process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

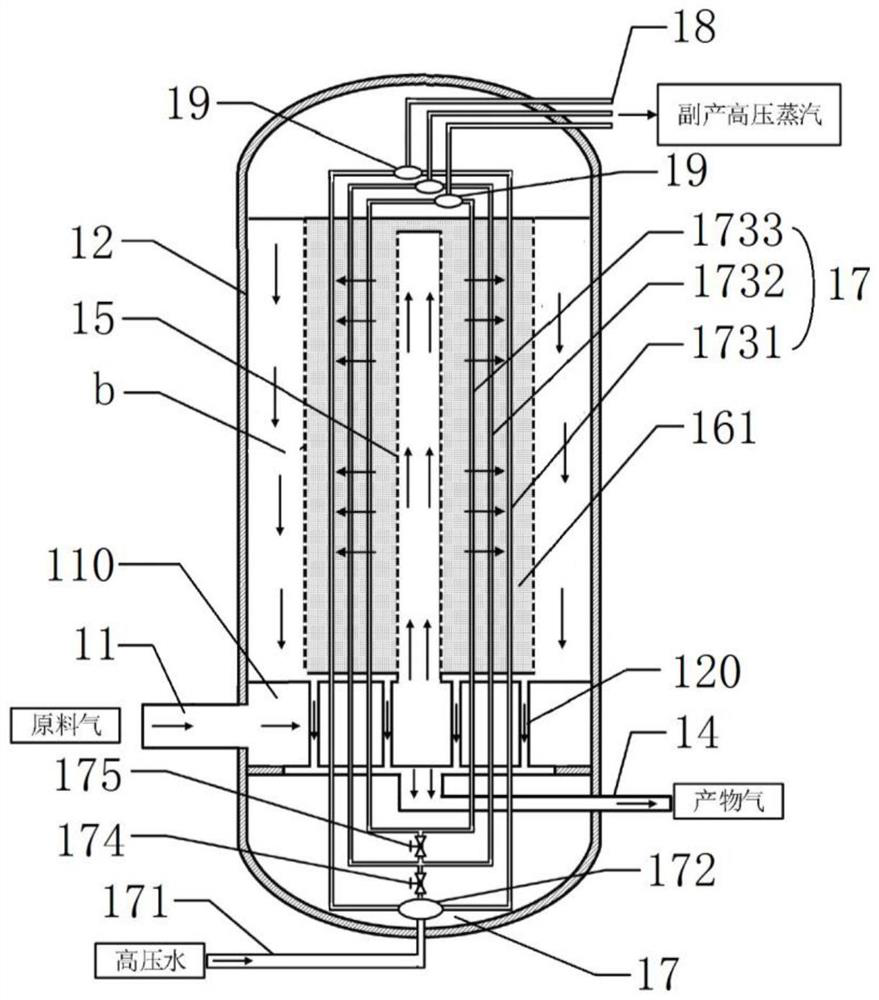

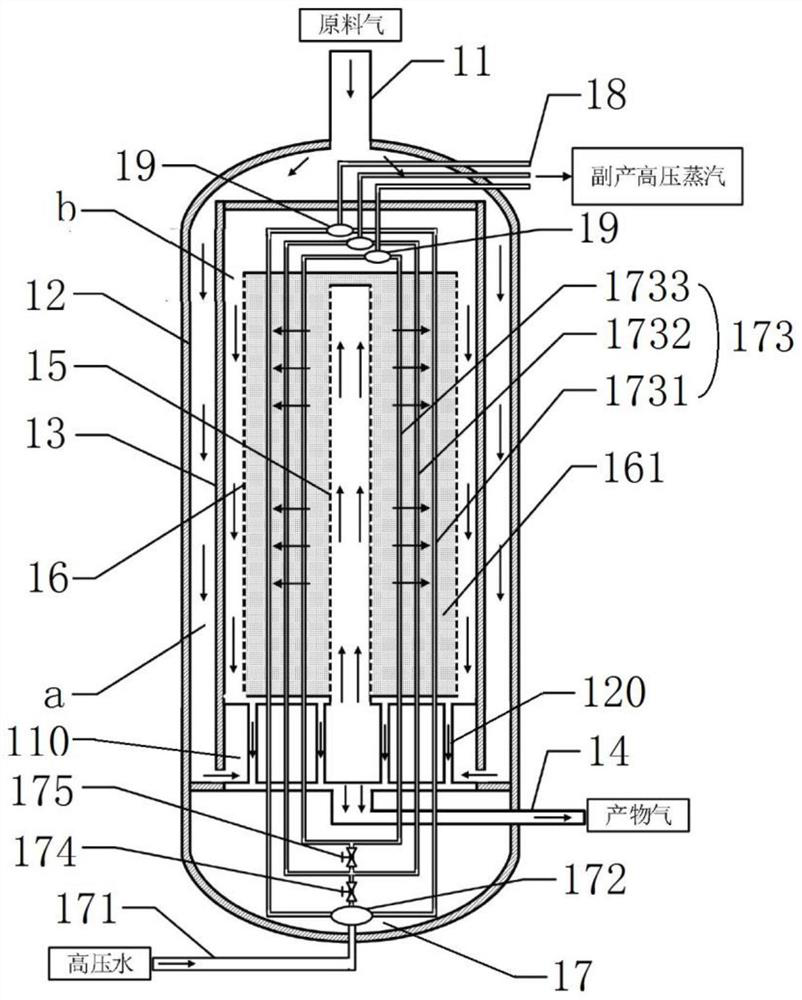

[0059] Ammonia tower level:

[0060] The volume ratio of hydrogen to nitrogen at the inlet of the raw material gas into the pipe is 2.5:1, the pressure is 10MPa, and the temperature is 25°C;

[0061] Ammonia synthesis catalyst bed, the space velocity is 5000h -1 ;

[0062] The catalyst bed outlet temperature is 400°C;

[0063] The inlet pressure of the high-pressure water in the water inlet pipe is 16.5MPa, and the temperature is 25°C;

[0064] The temperature of the high-pressure steam at the outlet of the steam pipeline is 350°C and the pressure is 16.5MPa;

[0065] The medium-pressure steam at the outlet of the steam pipeline has a temperature of 320°C and a pressure of 11MPa;

[0066] The ammonia concentration at the outlet of the product gas outlet pipe is 21.5%.

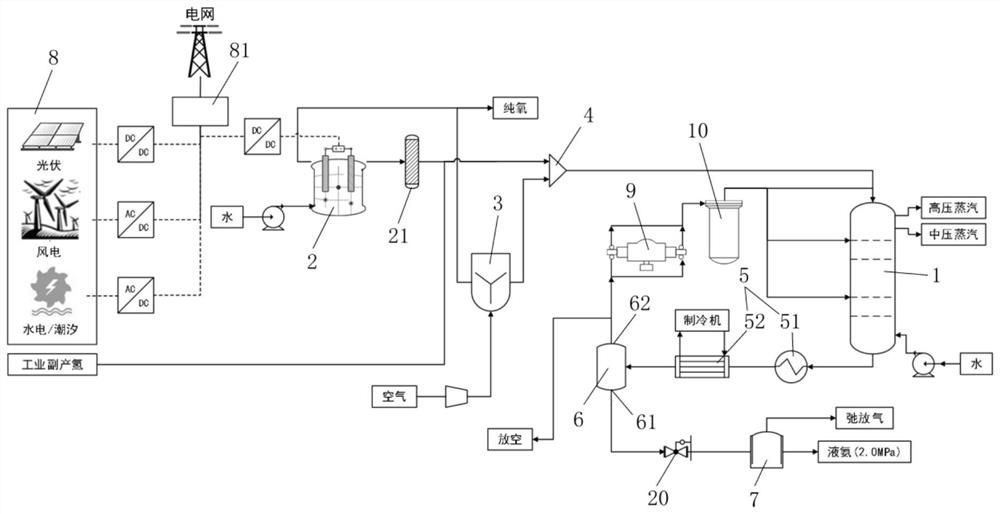

[0067] System technology level:

[0068] In the grid-connected mode, the renewable energy is connected to the grid within the capacity allowed by the grid, and the excess power is used to electrolyze wate...

Embodiment 2

[0075] Ammonia tower level:

[0076] The volume ratio of hydrogen to nitrogen at the inlet of the raw material gas into the pipe is 2.5:1, the pressure is 7MPa, and the temperature is 25°C;

[0077] Ammonia synthesis catalyst bed, the space velocity is 5000h -1 ;

[0078] The catalyst bed outlet temperature is 400°C;

[0079] The inlet pressure of the high-pressure water in the water inlet pipe is 16.5MPa, and the temperature is 25°C;

[0080] The temperature of the high-pressure steam at the outlet of the steam pipeline is 350°C and the pressure is 16.5MPa;

[0081] The medium-pressure steam at the outlet of the steam pipeline has a temperature of 320°C and a pressure of 11MPa;

[0082] The ammonia concentration at the outlet of the product gas outlet pipe is 16.8%.

[0083] System technology level:

[0084] The working pressure of the electrolyzed water device is 7.5MPa, and the working temperature is 80°C;

[0085] The hydrogen-nitrogen volume ratio of raw material g...

Embodiment 3

[0091] Ammonia tower level:

[0092] The volume ratio of hydrogen to nitrogen at the inlet of the raw material gas into the pipe is 2.5:1, the pressure is 10MPa, and the temperature is 25°C;

[0093] Ammonia synthesis catalyst bed, the space velocity is 5000h -1 ;

[0094] The catalyst bed outlet temperature is 400°C;

[0095] The inlet pressure of the high-pressure water in the water inlet pipe is 14MPa, and the temperature is 25°C;

[0096] The temperature of the high-pressure steam at the outlet of the steam pipeline is 360°C and the pressure is 14MPa;

[0097] The medium-pressure steam at the outlet of the steam pipeline has a temperature of 340°C and a pressure of 11MPa;

[0098] The temperature of the low-pressure steam at the outlet of the steam pipeline is 320°C and the pressure is 8MPa;

[0099] The ammonia concentration at the outlet of the product gas outlet pipe is 21.5%.

[0100] System technology level:

[0101] The working pressure of the electrolyzed wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com