Anti-cracking and corrosion-resistant mortar and preparation method thereof

A corrosion-resistant and anti-cracking technology, which is applied in the field of building construction mortar, can solve problems such as cracking and corrosion damage, and achieve the effects of enhancing stability and safety, improving wear resistance, and ensuring wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The invention provides an anti-cracking and corrosion-resistant mortar, comprising: 24.60kg of cement, 16.60kg of water, 3.10kg of latex powder, 6.40kg of basalt fiber, 4.40kg of composite reinforcing agent, and 44.90kg of quartz sand; The composite reinforcing agent includes: 0.3696kg of silver nitrate, 0.4136kg of glucose, 0.3256kg of graphene oxide, 0.4752kg of polyimide fiber, 0.8272kg of hollow glass microspheres, 0.3432kg of nano-titanium dioxide , 0.0132kg of silane coupling agent KH570, 1.6324kg of epoxy resin;

[0026] The present invention also provides a preparation method of anti-cracking and corrosion-resistant mortar, the specific preparation steps are as follows:

[0027] Step 1: Weigh silver nitrate, glucose, graphene oxide, polyimide fiber, hollow glass microspheres, nano-titanium dioxide, silane in the above weight parts of cement, latex powder, basalt fiber, water, quartz sand and composite reinforcing agent Coupling agent KH570 and epoxy resin;

[...

Embodiment 2

[0034] Different from Example 1, it includes: 25.80kg of cement, 17.80kg of water, 3.50kg of latex powder, 8.20kg of basalt fiber, 5.20kg of composite reinforcement, 39.50kg of quartz sand; the composite reinforcement Calculated according to weight percentage, it includes: 0.4784kg of silver nitrate, 0.5304kg of glucose, 0.4264kg of graphene oxide, 0.5928kg of polyimide fiber, 1.0088kg of hollow glass microspheres, 0.4368kg of nano-titanium dioxide, 0.026kg of Silane coupling agent KH570, 1.7004kg of epoxy resin.

Embodiment 3

[0036] All different from Example 1-2, including: 25.20kg of cement, 17.20kg of water, 3.30kg of latex powder, 7.30kg of basalt fiber, 4.80kg of composite reinforcing agent, 42.20kg of quartz sand; The composite reinforcing agent includes: 0.4224kg of silver nitrate, 0.4704kg of glucose, 0.3744kg of graphene oxide, 0.5328kg of polyimide fiber, 0.9168kg of hollow glass microspheres, 0.3888kg of nano-titanium dioxide, 0.0192kg of silane coupling agent KH570, 1.6752kg of epoxy resin.

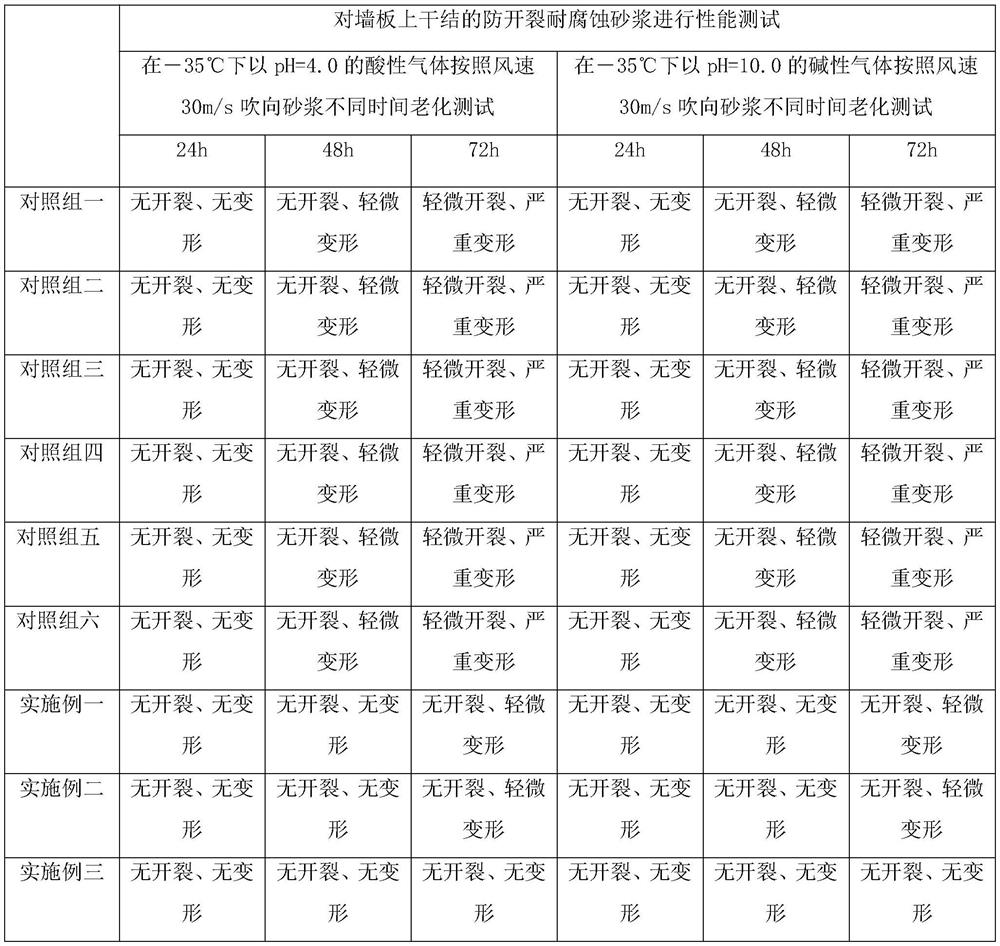

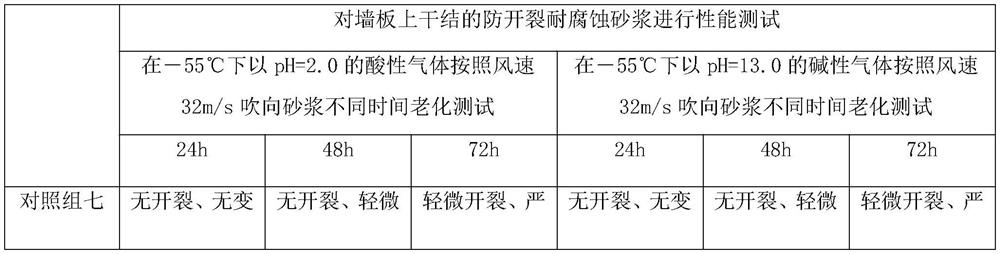

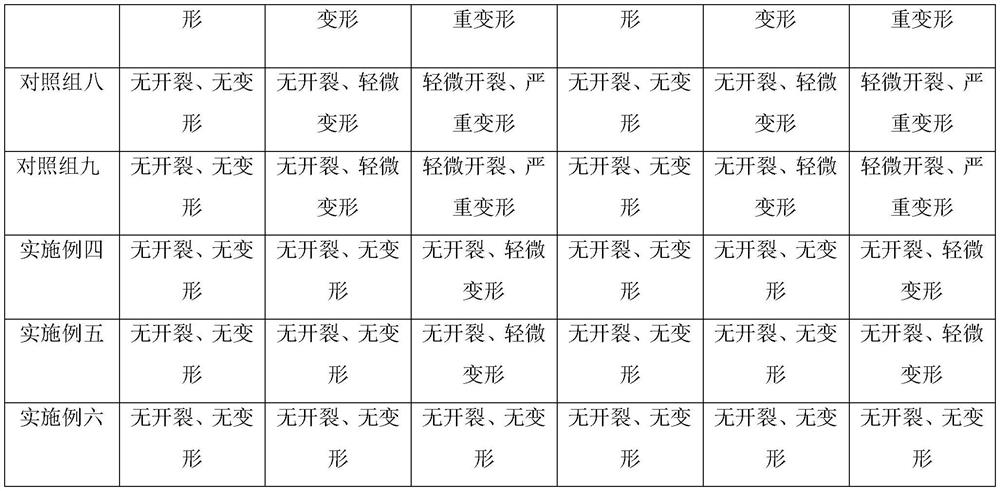

[0037] Get the anti-cracking and corrosion-resistant mortar that above-mentioned embodiment 1-3 makes and the anti-cracking and corrosion-resistant mortar of control group one, the anti-cracking and corrosion-resistant mortar of control group two, the anti-cracking and corrosion-resistant mortar of control group three, control group The anti-cracking and anti-corrosion mortar of four, the anti-cracking and anti-corrosion mortar of matching group five and the anti-cracking and anti-corrosion mortar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com