Liquid crystal elastomer and preparation method thereof and liquid crystal driving element

A technology of liquid crystal elastomers and liquid crystal monomers, applied in liquid crystal materials, chemical instruments and methods, etc., can solve the problems of inability to further elongate, large energy consumption, severe conditions, etc., and achieve excellent stability and high driving stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a preparation method of a liquid crystal elastomer, which comprises the step (a) of obtaining a liquid crystal elastomer through polymerization reaction of a liquid crystal monomer, a chain extender and a crosslinking agent.

[0024] In step (a), the liquid crystal monomer is selected from double-ended acrylate liquid crystal monomers. In some embodiments, both ends of the main chain of the double-ended acrylate liquid crystal monomer are acrylate groups. In some embodiments, preferably, the liquid crystal monomer is selected from compounds described in formula (I).

[0025]

[0026] In formula (I), R 1 , R 2 , R 3 , R 4 independently represent hydrogen or methyl, R 5 and R 6 Each independently represents a C3-C6 alkylene group.

[0027] In some embodiments, R 1 , R 2 , R 3 , R 4 One or more of them represent a methyl group. Optionally, R 1 , R 2 , R 3 , R 4 One of them represents a methyl group, and the rest represent hydrogen....

Embodiment 1

[0060] At 25°C, 0.8 mmol of liquid crystal monomer RM257, 0.6 mmol of chain extender 2,2'-(1,2-ethylenedioxy)diethanethiol and 0.1 mmol of crosslinking agent tetrakis(3-mercapto Propionate) pentaerythritol ester was added to dichloromethane to obtain a mixed solution. The total mass fraction of liquid crystal monomer, chain extender and crosslinking agent in the mixed solution is 20wt%. Based on the total mass of the liquid crystal monomer, the chain extender and the crosslinking agent in the mixed solution, 1 wt% of the catalyst dipropylamine was added to the mixed solution. The mixed solution containing the catalyst was poured into a polytetrafluoroethylene mold, and polymerized at 25° C. for 12 hours. After the reaction, the polymer is released from the mold to obtain a liquid crystal elastomer.

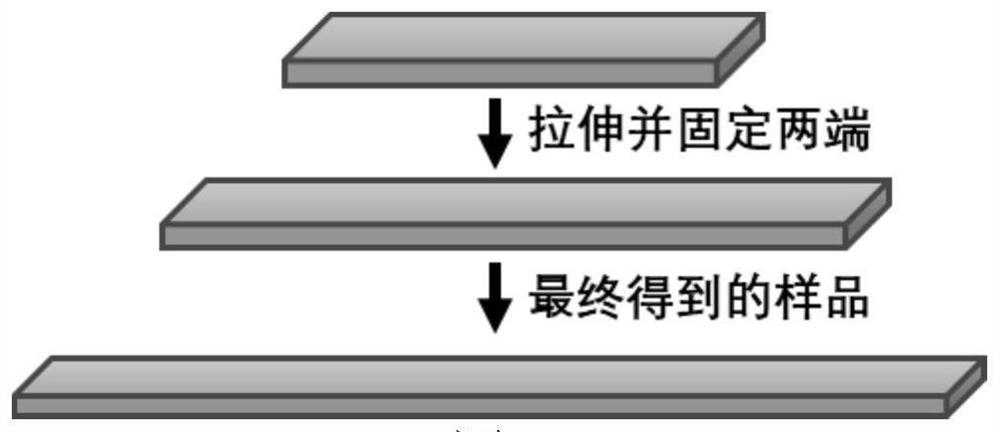

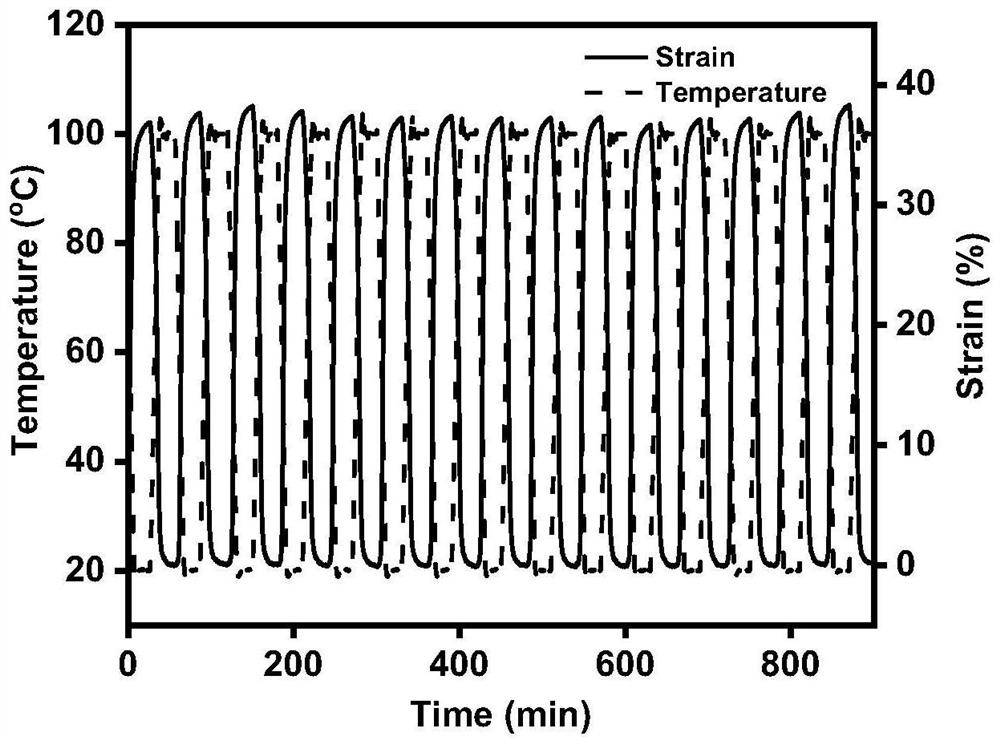

[0061] refer to figure 1 , the liquid crystal elastomer was cut into strips with a length of 15mm, a width of 1.5mm, and a thickness of 0.12mm, and uniaxially stretched along t...

Embodiment 2

[0064]At 25°C, 0.8 mmol of liquid crystal monomer RM257, 0.6 mmol of chain extender 2,2'-(1,2-ethylenedioxy)diethanethiol and 0.1 mmol of crosslinking agent tetrakis(3-mercapto Propionate) pentaerythritol ester was added to dichloromethane to obtain a mixed solution. The total mass fraction of liquid crystal monomer, chain extender and crosslinking agent in the mixed solution is 20wt%. Based on the total mass of the liquid crystal monomer, the chain extender and the crosslinking agent in the mixed solution, 1 wt% of the catalyst dipropylamine was added to the mixed solution. The mixed solution containing the catalyst was poured into a polytetrafluoroethylene mold, and polymerized at 25° C. for 12 hours. After the reaction, the polymer is released from the mold to obtain a liquid crystal elastomer.

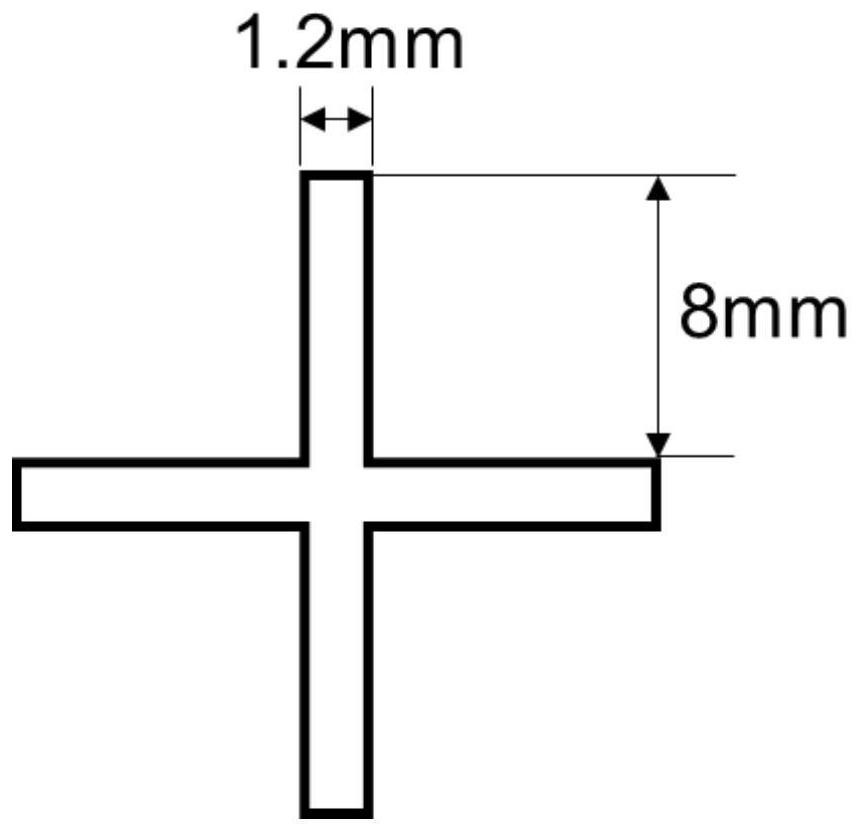

[0065] Cut the liquid crystal elastomer with a thickness of 0.15mm as image 3 In the cruciform shape shown, the four arms are equal in size, each 8mm long and 1.2mm wide. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com