Power system with AMT and hydraulic torque converter and control method of power system

A hydraulic torque converter and power system technology, which is applied in the power system with AMT and hydraulic torque converter and its control field, can solve the problems of insufficient stability of power output, so as to improve stability, improve braking effect, The effect of improving shift performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

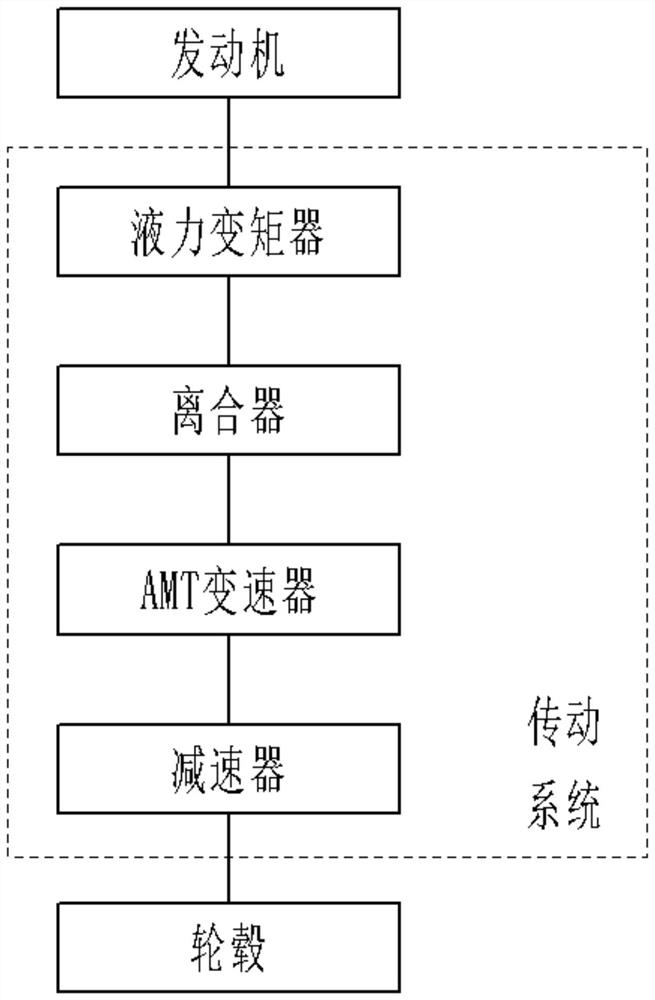

[0032] Such as figure 1 As shown, a power system with an AMT and a torque converter includes an engine and a hub, the engine drives the hub through a transmission system, and the transmission system includes a torque converter, a clutch, and an AMT gearbox connected in sequence and reducer, where the torque converter connects the engine to the clutch.

[0033] As described above, the present application provides a power system with an AMT and a torque converter. Compared with the prior art, the solution uses a hydraulic torque converter between the engine and the clutch. As a result, the engine and the AMT gearbox are not only rigidly connected through the clutch, but the hydraulic torque converter with separate guide wheels and turbines realizes a flexible connection between the engine and the gearbox, avoiding the AMT gearbox. Poor combination of gear speed regulation and slow combination of clutch leads to intermittent power output, driving stumbles and stalling. The pow...

Embodiment 2

[0035] The present embodiment is further limited on the basis of embodiment 1:

[0036] In order to meet the requirement that special vehicles have sufficient power sources under harsh driving conditions, the parameters of the engine and clutch are selected and set as follows: the maximum torque of the engine is greater than 2000N*m, the maximum power is greater than 330kw, and the maximum speed is less than 2500r / min; The clutch adopts a double-plate clutch, and the performance of the clutch meets: its maximum transmission torque is greater than 3000N*m, the pressing force is greater than 17000N and less than 19000N, and the separation stroke is greater than 15mm and less than 20mm.

[0037] The hydraulic torque converter is a centrifugal lock-up hydraulic torque converter, and the performance of the hydraulic torque converter satisfies: when the engine speed is less than 2200r / min, the hydraulic torque converter outputs power flexibly; when the engine speed is When it is gre...

Embodiment 3

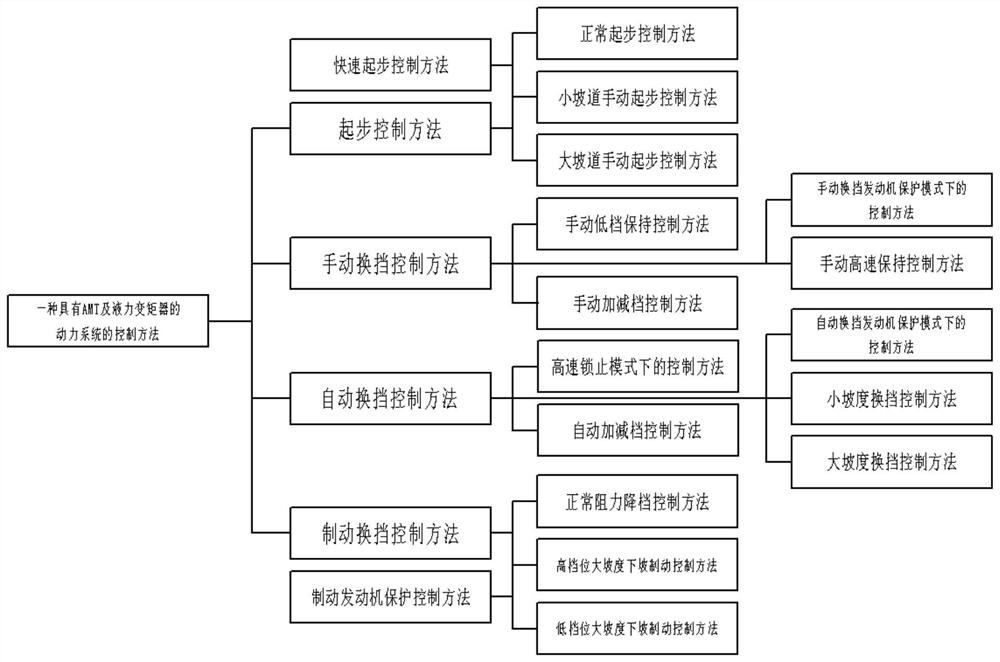

[0039] Such as figure 2As shown, the present application also provides a control method of a power system with an AMT and a hydraulic torque converter. The method is a control method based on any one of the aforementioned power systems with AMT and hydraulic torque converter; the control method includes at least one of the following methods: start control method, including fast start mode, normal start mode, Small ramp manual start mode, large ramp manual start mode; manual shift control method, including manual low gear hold mode, manual shift engine protection mode, manual upshift control method, manual high speed hold mode; automatic shift control method, Including high-speed locking mode, automatic shift engine protection mode, automatic shift mode, small slope shift mode, large slope shift mode; brake shift control method, including brake engine protection mode, normal resistance downshift mode , high-grade steep downhill braking mode, low gear steep downhill braking mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com