Ship incinerator waste heat recycling system

A technology of waste heat recovery and incinerator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The implementation of the present invention will be described in detail below in conjunction with the examples of implementation, but they do not constitute a limitation of the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand.

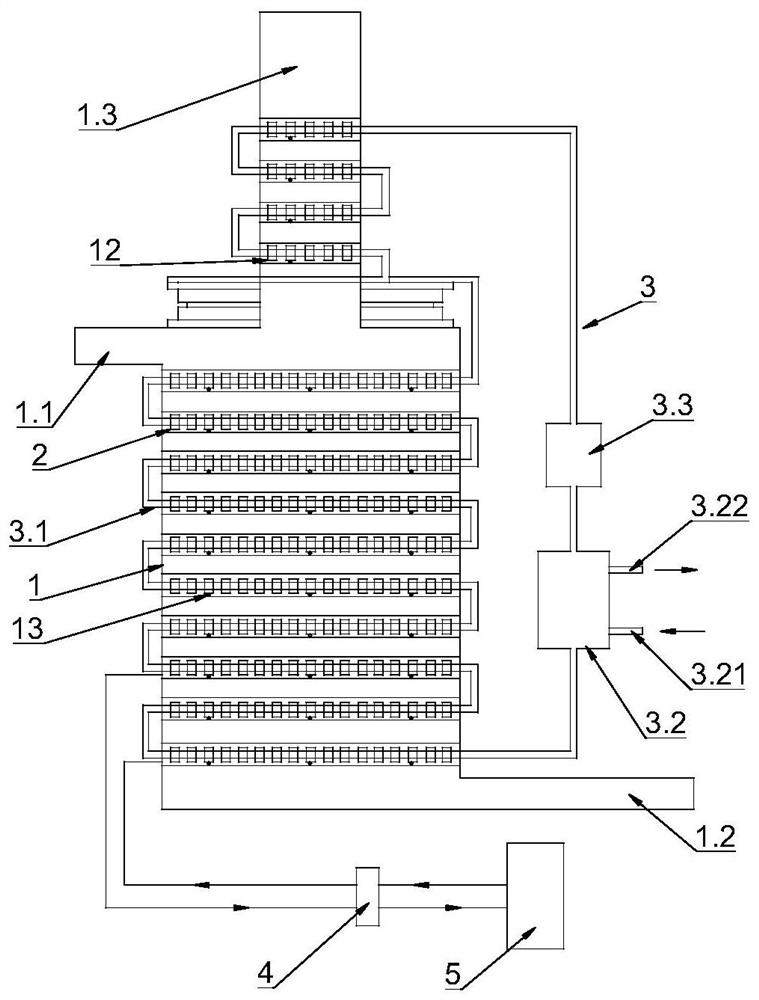

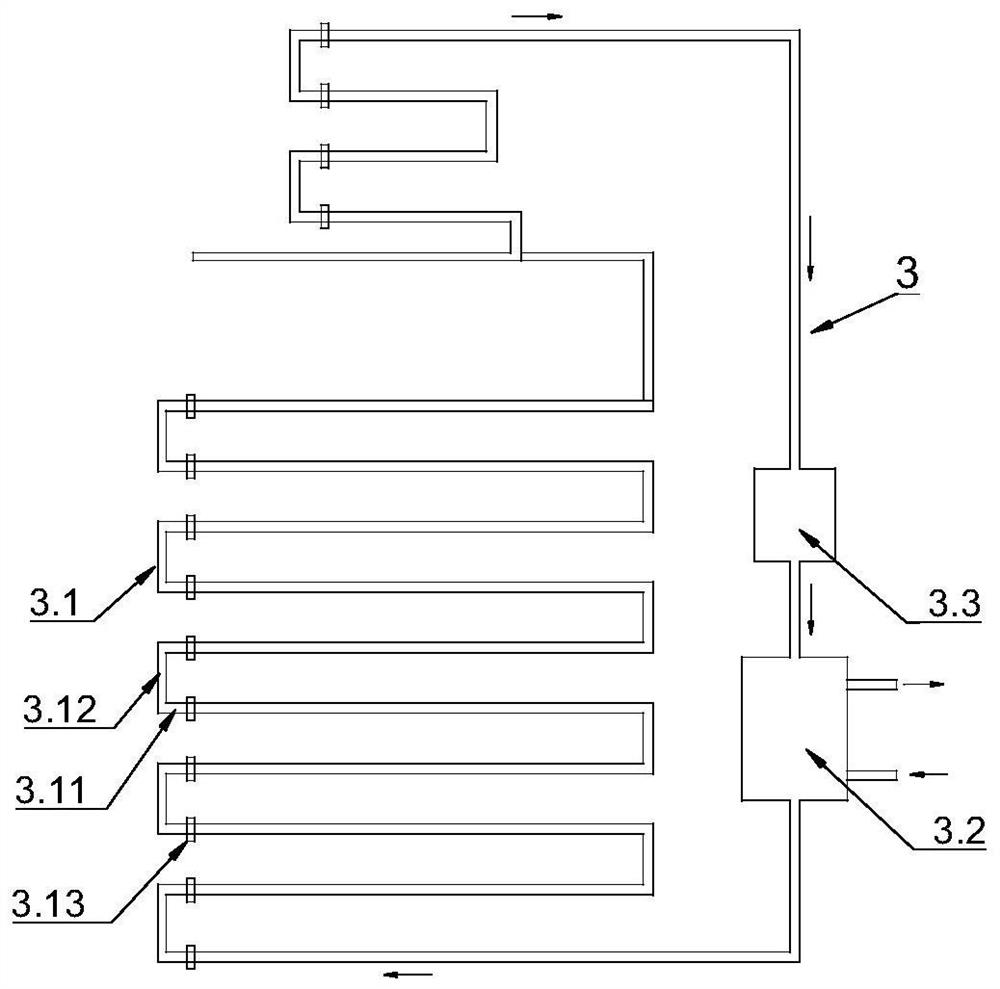

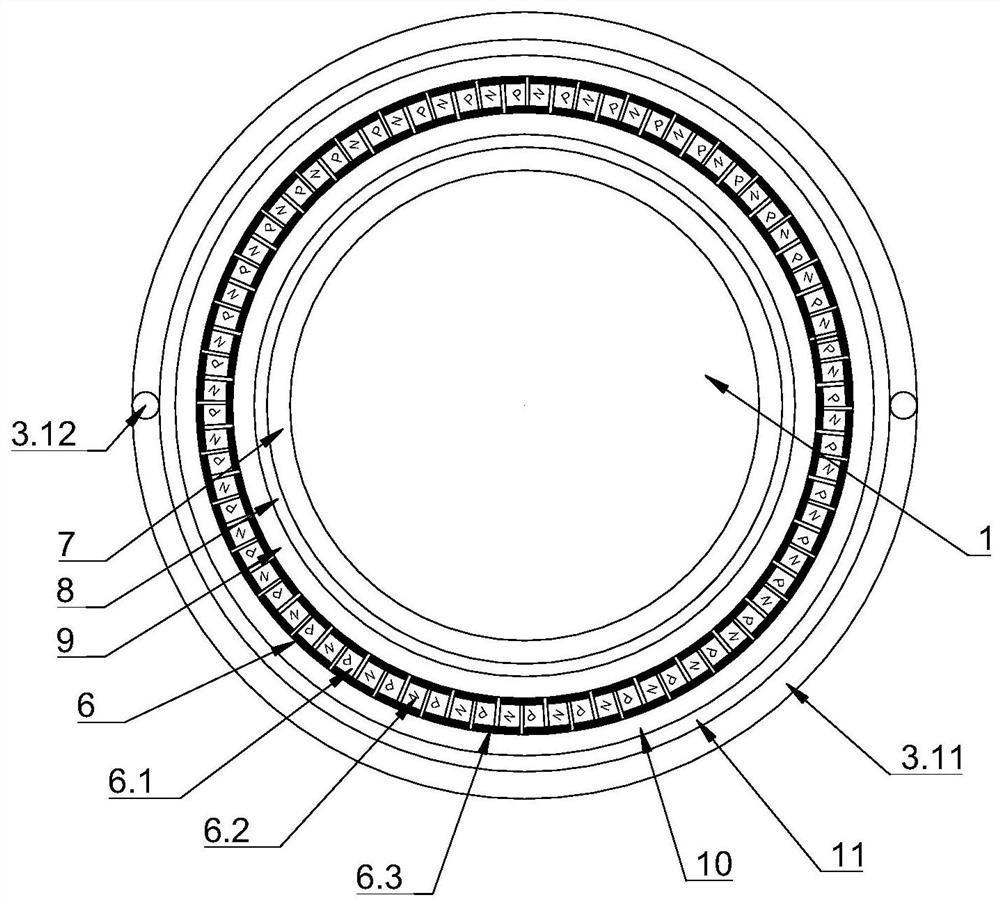

[0031] Such as figure 1 and figure 2 A ship incinerator waste heat recovery and utilization system shown is proposed for the loss of heat energy of the ship incinerator, and is used to recover the waste heat of the ship incinerator 1. The ship incinerator 1 is provided with a feed port 1.1, a discharge port 1.2 and Exhaust port 1.3, which includes thermoelectric conversion device 2, cooling water system 3, rectifier circuit 4 and storage battery 5; the furnace outer wall of ship incinerator 1 is surrounded by several thermoelectric conversion devices 2 from top to bottom, and several thermoelectric conversion devices The outer ring of the device 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com