Turbine blade laser cladding detection device and detection method

A technology for steam turbine blades and laser cladding, applied in the field of blade processing, can solve the problems affecting the output power and service life of the unit, the steam inlet edge of the blade tip, and the blade endangering the safe operation of the unit, so as to reduce the measurement cost, release the production capacity, and ensure that the The effect of cladding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

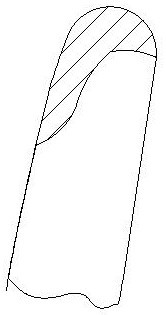

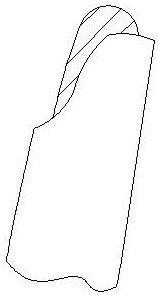

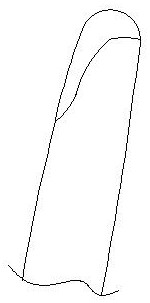

[0024] Such as Figure 4-Figure 8 A laser cladding detection device for a steam turbine blade is shown, which includes a cladding area marking line sample 1, a cladding groove shape sample 2, a cladding area clamping sample 3, a cladding area thickness sample 4, and a cladding repair welding Sample 5, when in use, can be placed on the conventional detection frame, and designed according to the shape of the actual gear height; combined with Figure 4 , the cladding zone line sample block 1 includes a sharp edge 11 for marking the inner arc surface of the blade to be processed and the back camber surface of the blade profile, and the cladding zone line sample block 1 also includes The scribed groove 13 in the middle of the sample block, the inner surface of the scribed groove is the inlet side positioning surface 12, the inlet side locating surface 12 is used to contact the inlet edge of the blade 100 to be processed, the two ends of the scribed groove 13 with sharp edges 11, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com