Method for manufacturing anti-corrosion pipe fittings for superheater and pipe bending device

A manufacturing method and technology of pipe bending device, applied in the direction of pipes/pipe joints/fittings, pipeline protection, pipeline anticorrosion/rust protection, etc., can solve the problems of low cladding construction efficiency and inability to guarantee cladding quality, etc. Cladding quality, small deformation at the bending position, and the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

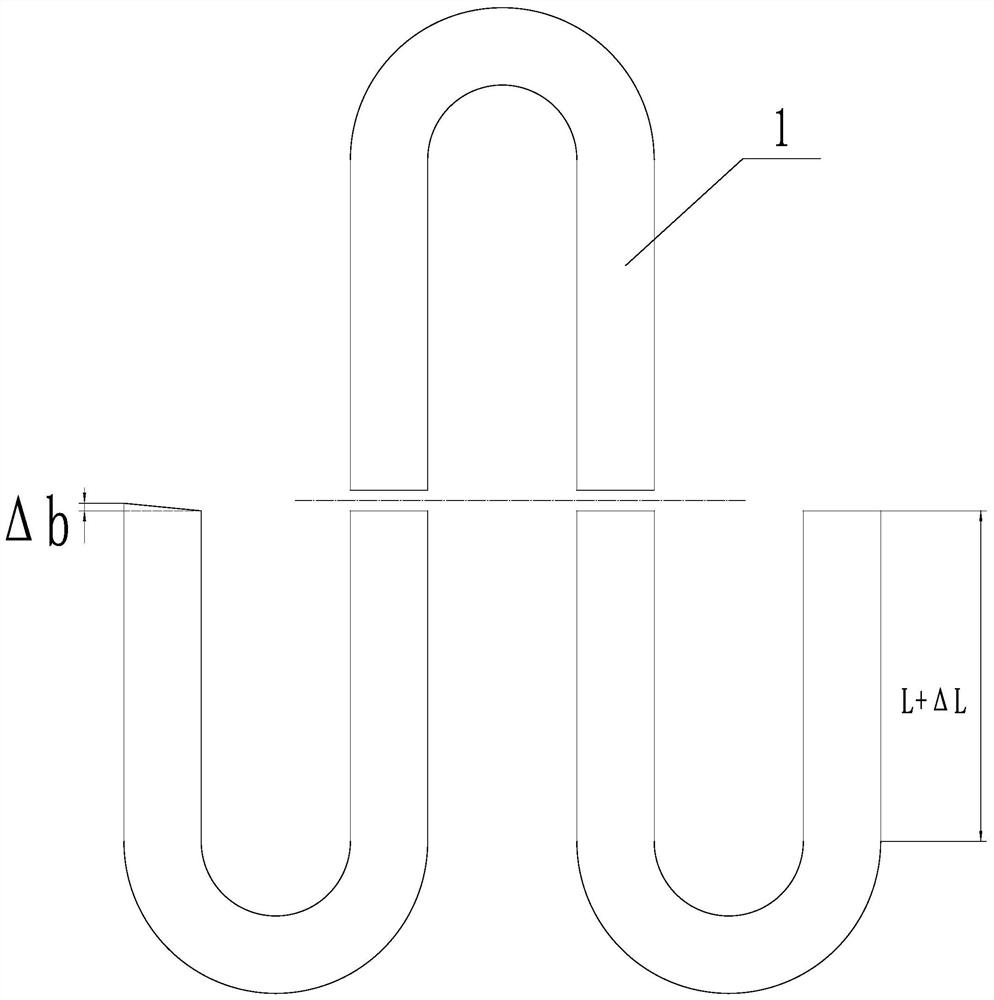

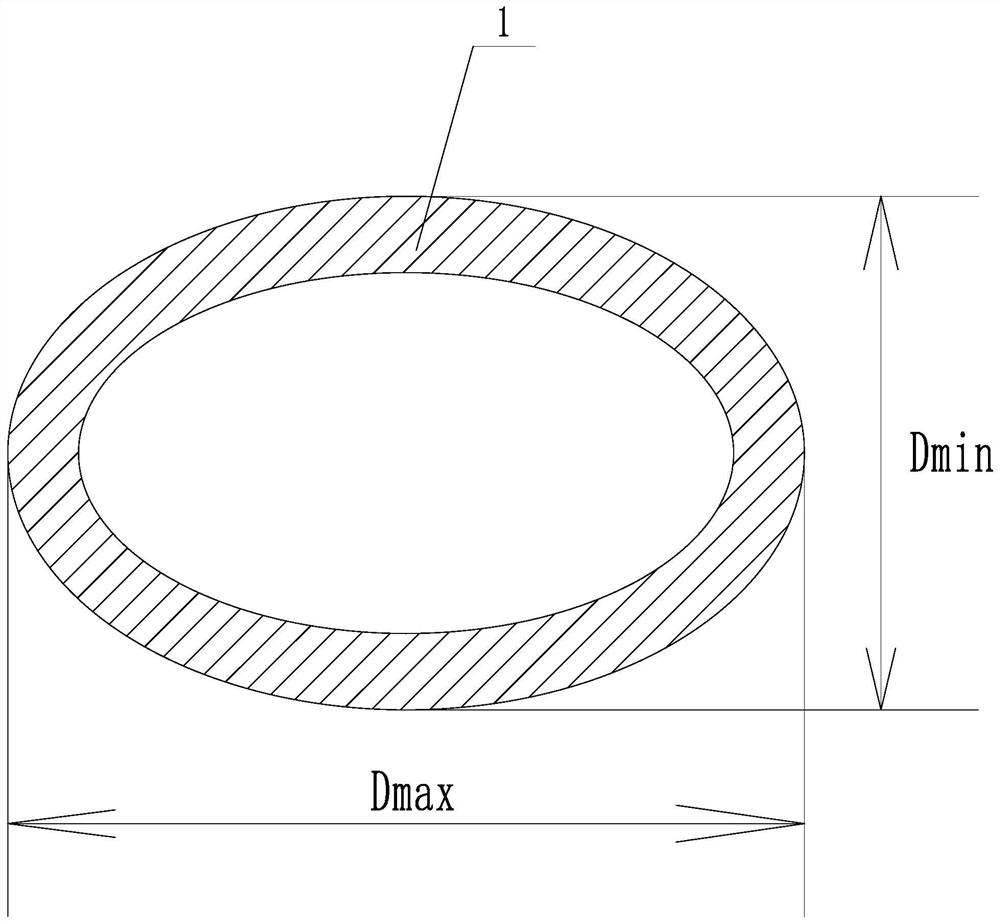

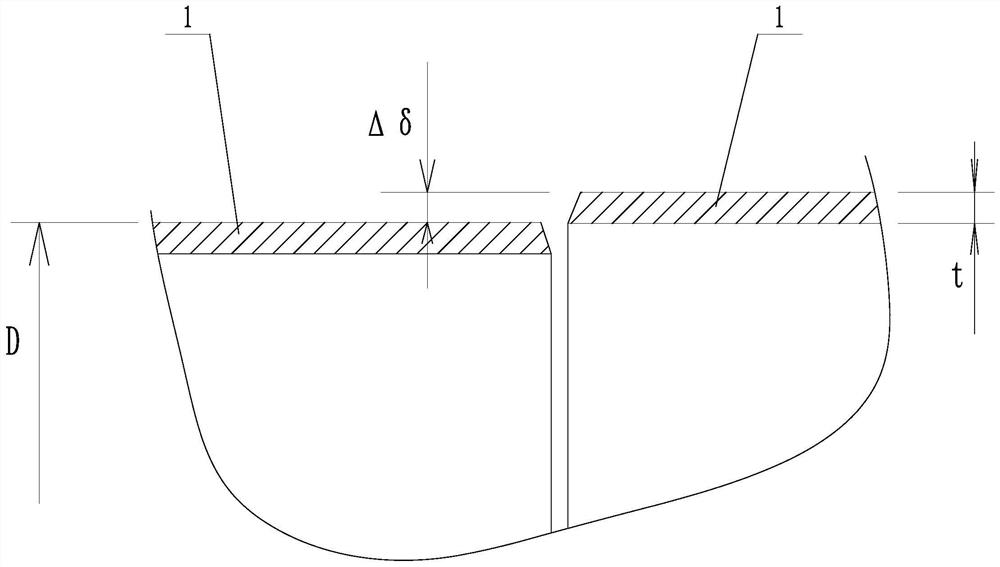

[0026] Embodiment: A kind of superheater anti-corrosion pipe fitting manufacturing method (see attached figure 1 to attach image 3 ), including the following steps: a, cladding the alloy protective layer on the surface of the pipe fitting blank; b, blanking, cutting the pipe fitting blank covered with the alloy protective layer into several bent pipe sections; c, performing bending operation on the bent pipe section ; d. Splicing the bent pipe sections 1 end-to-end in sequence to form a superheater anti-corrosion pipe fitting. The alloy protective layer is made of nickel-based alloy material.

[0027] Before blanking in step b, check the pipe fitting blank. Check that the size and material of the pipe fitting blank must be consistent with the drawing. The alloy protective layer on the surface of the pipe fitting blank must be fully covered. And cracks, block defects. Before blanking in step b, after the inspection of the blank of the pipe fitting is completed, the blank of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com